Composite floor

A composite floor and composite board technology, applied in the field of building decoration materials, can solve problems such as surface hardness, lack of wear resistance, insufficient comfort of the reinforced floor, and complex production process of surface paint, so as to achieve high wear resistance and precious protection. Colorful effects of trees and decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

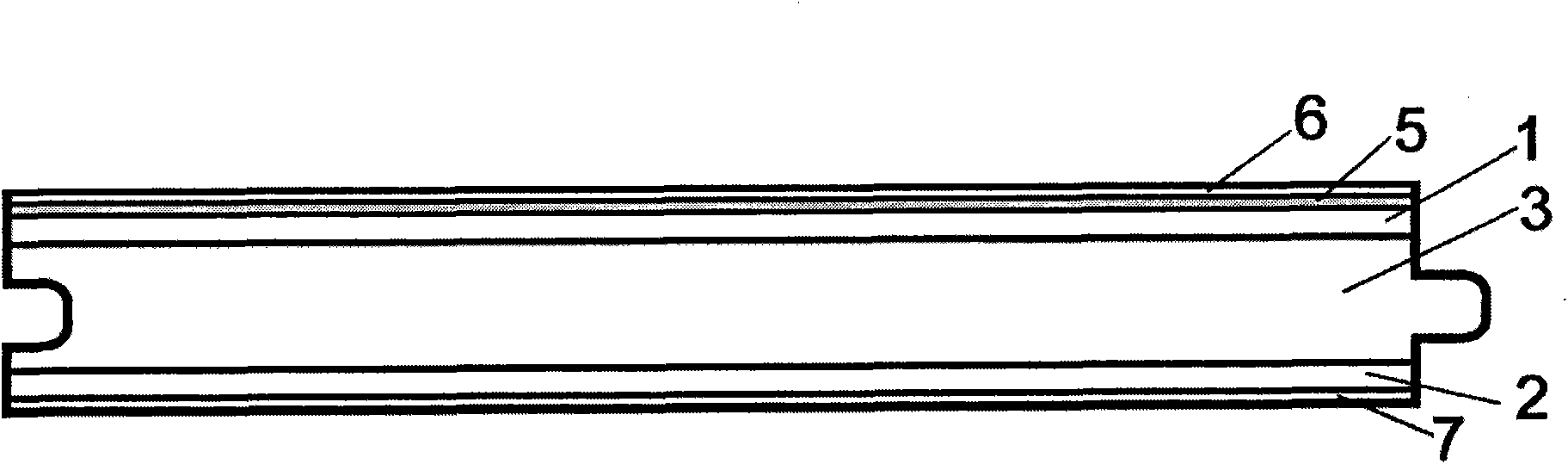

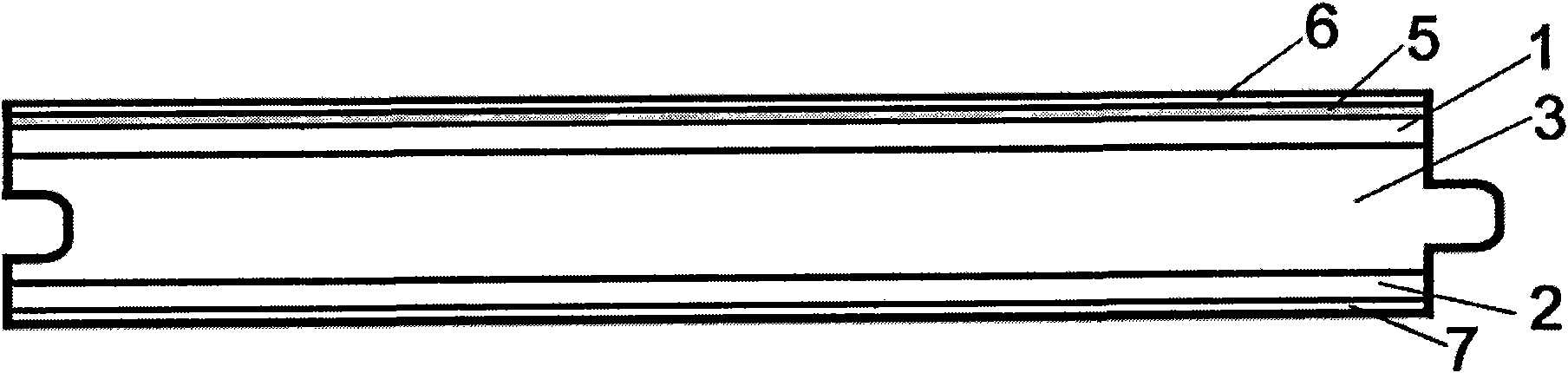

[0024] Such as figure 1 As shown, a compound flooring includes a first density board 1 , a multi-layer solid wood composite board 3 and a second density board 2 . The first density board 1, the multi-layer solid wood composite board 3, and the second density board 2 are sequentially bonded and hot-pressed by an adhesive to form a whole.

[0025] The upper part of the first density board 1 is provided with a decorative finish layer 5, and the decorative finish layer 5 is wood grain paper. The surface of the decorative finish layer 5 is provided with an aluminum oxide wear-resistant layer 6 .

[0026] The wood grains of the adjacent solid wood single-layer boards of the multi-layer solid wood composite board 3 are staggered vertically and horizontally, and the interlayers are bonded and hot-pressed with an adhesive to form a whole.

[0027] The lower bottom surface of the second density board 2 is provided with a balance paper 7, which can maintain the balance of the floor, an...

Embodiment 2

[0029] The difference between this embodiment and the first embodiment is that: the lower bottom surface of the second density board 2 is provided with an aluminum-plastic composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com