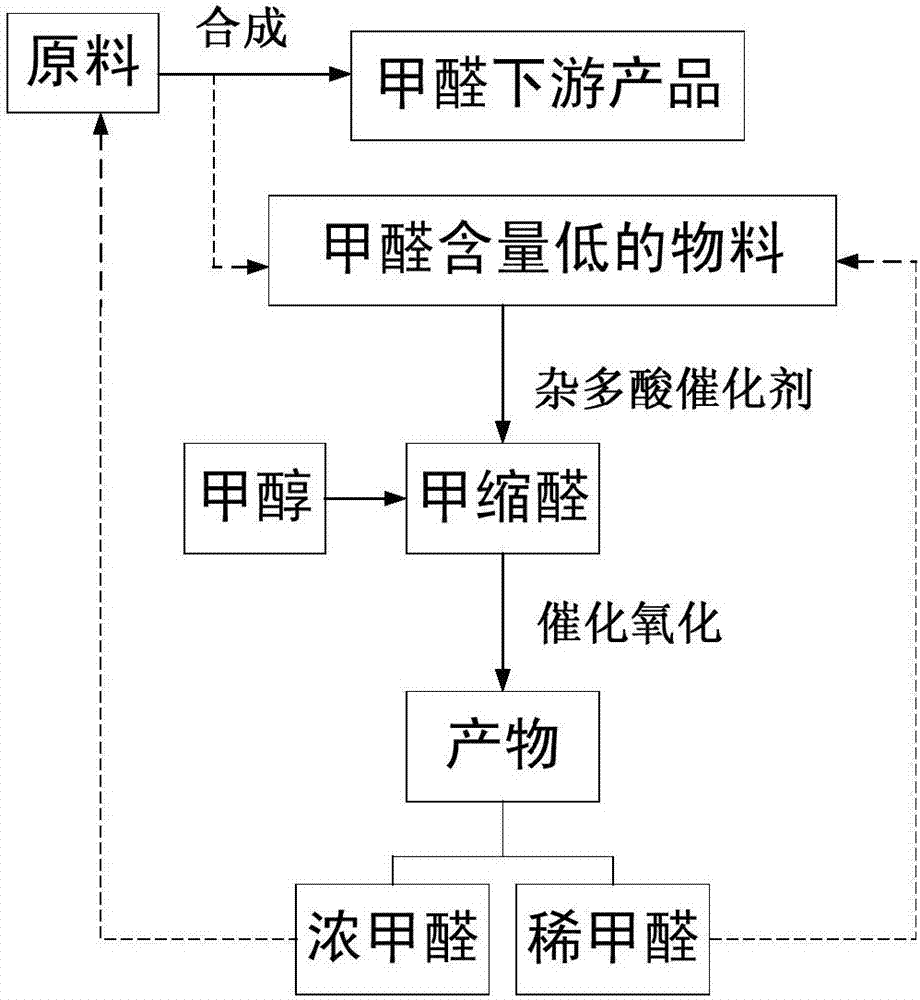

Method for preparing concentrated formaldehyde from low-formaldehyde-content materials

A formaldehyde content, concentrated formaldehyde technology, applied in the field of preparation of concentrated formaldehyde, can solve the problems of reducing formaldehyde, formaldehyde is easy to oxidize, corrode equipment, etc., and achieve the effect of simple preparation process, easy industrialization, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

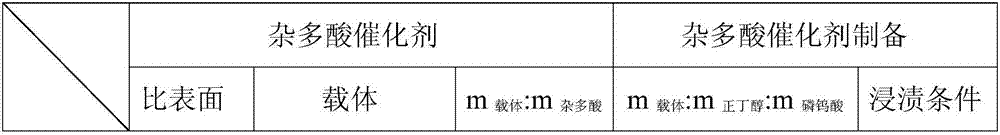

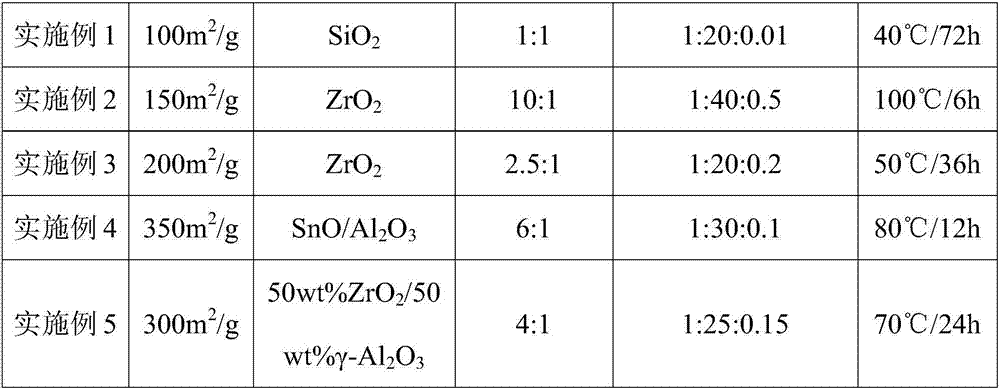

Examples

Embodiment 1

[0051] 1) Collect the intermediate product in the process of producing polyoxymethylene dimethyl ether, wherein the concentration of formaldehyde is 5wt%, add methanol to the intermediate product, wherein the volume ratio of methanol to the intermediate product is 0.2:1, and then add the loaded Phosphotungstic acid catalyst, made into slurry, stirred and reacted to obtain methylal; wherein, the relevant parameters and preparation conditions of the catalyst catalyst are shown in Table 1, and the mass ratio of the added catalyst to the intermediate product is 0.5:1;

[0052] 2) Under the oxygen partial pressure of 0.2 and 320°C, the methylal obtained in step 1) is catalyzed and oxidized under the action of iron molybdate, molybdenum trioxide and catalytic promoter, and the product is collected. The relevant parameters of the catalyst are shown in Table 2, which are spherical particles with a diameter of 1 mm.

Embodiment 2

[0056] 1) Collect the intermediate product in the process of producing paraformaldehyde, wherein the concentration of formaldehyde is 25wt%, add methanol to the intermediate product, wherein the volume ratio of methanol to the intermediate product is 0.8:1, then add the loaded phosphotungstic acid catalyst , making a slurry, stirring reaction to obtain methylal; wherein, the relevant parameters and preparation conditions of the catalyst catalyst are as shown in Table 1, and the mass ratio of adding the catalyst to the intermediate product is 1.2:1;

[0057] 2) Catalytic oxidation of the methylal obtained in step 1) under the action of iron molybdate, molybdenum trioxide and catalytic promoter under the oxygen partial pressure of 0.5 and 350° C. to collect the product. The relevant parameters of the catalyst are shown in Table 2, which are spherical particles with a diameter of 2 mm.

Embodiment 3

[0059] 1) collect the intermediate product of DMMn production process, wherein the concentration of formaldehyde is 10wt%, methanol is added in this intermediate product, wherein the volume ratio of methanol and this intermediate product is 0.5:1, then add load-type phosphotungstic acid catalyst, prepare Become slurry, stirring reaction obtains methylal; Wherein, the relevant parameter of catalyst catalyst and preparation condition are as shown in table 1, the mass ratio of adding catalyst and intermediate product is 0.6:1;

[0060] 2) Under the oxygen partial pressure of 0.3 and 335°C, the methylal obtained in step 1) is catalyzed and oxidized under the action of iron molybdate, molybdenum trioxide and catalytic promoter, and the product is collected. The relevant parameters of the catalyst are shown in Table 2, which is a hollow cylindrical ring structure with an outer diameter of 5.5 mm, an inner diameter of 2.5 mm, and a height of 5 mm. Dilute formaldehyde is returned to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com