UV-curing coating with formaldehyde-removing function, and formaldehyde-removing product and method for producing the same

A technology for curing coatings and formaldehyde, applied in the field of coatings and inks, can solve the problems of slow pollutants, limited adsorption amount, limited adsorption area, etc., and achieve the effects of improved catalytic degradation efficiency, good adhesion fastness, and fast light curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The formula of UV curable coating is: hyperbranched polyester acrylate (Zhongshan Qianyou company UV7200) 15 parts, thermoplastic resin (Taiwan production association company isobutyl methacrylate IBMA polymer AR-500) 16 parts, IBOA 55 parts, 3.0 parts of 1-hydroxycyclohexyl phenyl ketone, 1.5 parts of Degussa P25 nano titanium dioxide, 6.5 parts of 1250 mesh ultrafine talc powder, 12 parts of dispersant BYK-1112, 0.5 parts of 201 methyl silicone oil defoamer.

[0058] Stir 15 parts of the above-mentioned thermoplastic resin and 50 parts of IBOA at 50°C for 4.5 hours. After the dissolution is complete, mix it with the rest of the components and stir evenly at high speed. Grind it to a certain fineness with three rollers to obtain a UV with formaldehyde removal function. coating.

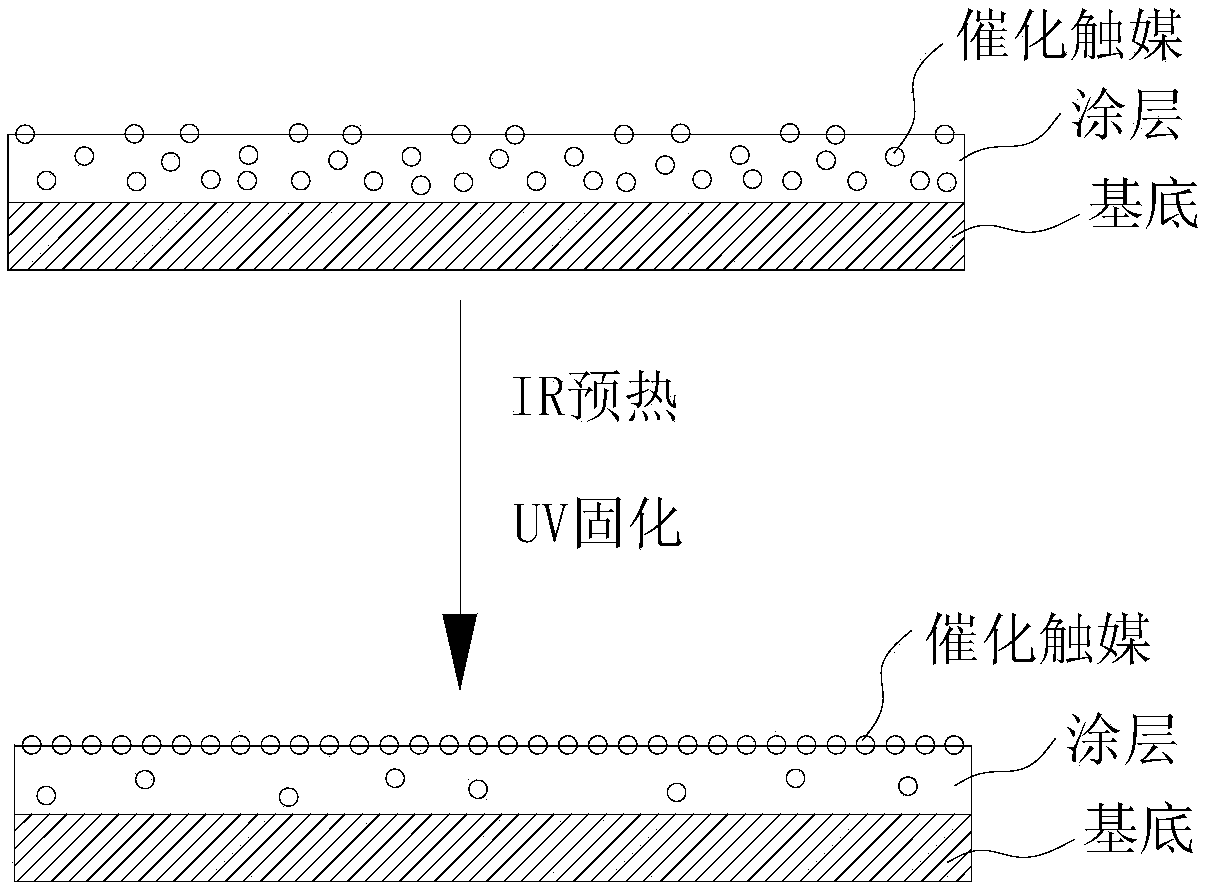

[0059] Coating, preheating and UV curing conditions: The surface tension of PET film (thickness 15 microns) after corona treatment is 42 dynes / cm, UV coating on both sides, thickness 5 microns...

Embodiment 2

[0061] The formula of UV curing coating is: 20 parts of hyperbranched polyester acrylate (B-570 of Boxing Technology), 15 parts of thermoplastic resin (HY-10 of Guangzhou Wuyi Chemical Industry), 54 parts of HDDA, 2,4,6- Trimethylbenzoyl-diphenylphosphine oxide (TPO) 2.0 parts, Degussa P25 nano-titanium dioxide 2.5 parts, fumed silica 5 parts, dispersant BYK-1101 parts, 201 methyl silicone oil defoamer 0.5 parts .

[0062] Stir 15 parts of the above-mentioned thermoplastic resin and 54 parts of HDDA at 50°C for 3.5 hours. After the dissolution is complete, mix with the rest of the components and stir evenly at a high speed. Grind to a certain fineness with three rollers to obtain a formaldehyde-removing product. UV coatings.

[0063] Coating, preheating and UV curing conditions: PET film (thickness 15 microns) has a surface tension of 42 dynes / cm after corona treatment, and UV coatings are coated on both sides with a thickness of 5 microns. The IR preheating temperature is 7...

Embodiment 3

[0065] The formula of UV curing coating is: 20 parts of hyperbranched polyester acrylate (B-570 of Boxing Technology), 15 parts of thermoplastic resin (HY-10 of Guangzhou Wuyi Chemical Industry), 52 parts of HDDA, 2,4,6- Trimethylbenzoyl-diphenylphosphine oxide (TPO) 2.0 parts, Degussa P25 nano-titanium dioxide 3.5 parts, fumed silica 6 parts, dispersant BYK-1101 parts, 201 methyl silicone oil defoamer 0.5 parts .

[0066] Stir 15 parts of the above-mentioned thermoplastic resin and 52 parts of HDDA at 50°C for 3.5 hours. After the dissolution is complete, mix it with the rest of the components and stir evenly at a high speed. Grind it to a certain fineness with three rollers to obtain a formaldehyde-removing product. UV coatings.

[0067] Coating, preheating and UV curing conditions: PET film (thickness 15 microns) has a surface tension of 42 dynes / cm after corona treatment, and UV coatings are coated on both sides with a thickness of 5 microns. The IR preheating temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com