Formaldehyde-removing plaster gypsum and preparation method thereof

A technology for plastering gypsum and formaldehyde, which is applied in the field of formaldehyde-removing plastering gypsum and its preparation, and can solve problems such as lack of functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

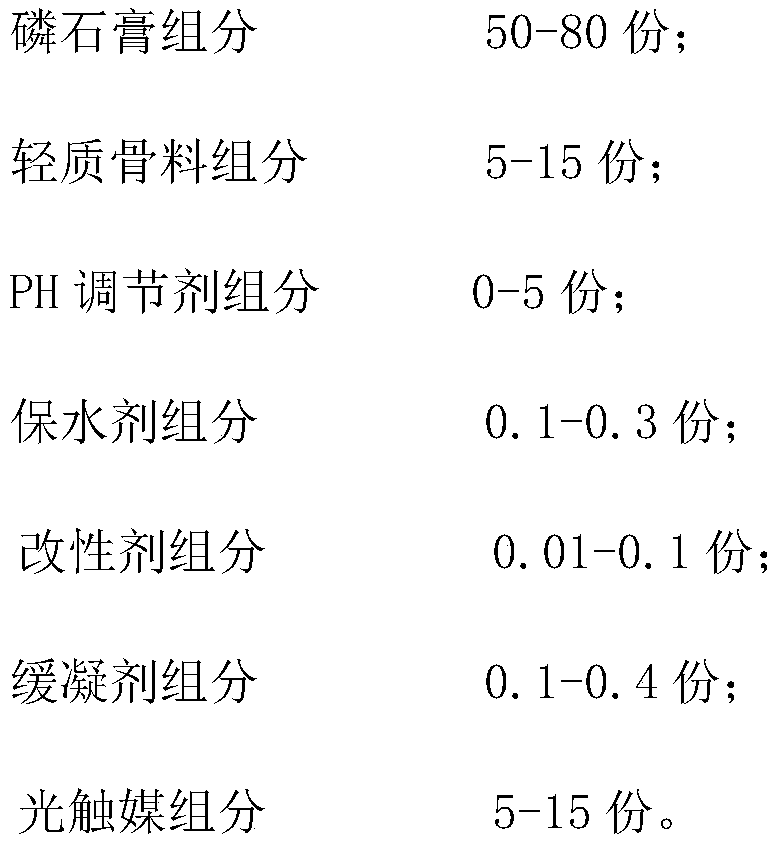

[0018] The formaldehyde-removing plastering gypsum provided in this embodiment includes a phosphogypsum component, a lightweight aggregate component, a pH regulator component, a water-retaining agent component, a modifier component, a set retarder component, and a photocatalyst component , each component is calculated in parts by weight:

[0019]

[0020] First weigh the PH regulator component, water retaining agent component, modifier component, retarder component and photocatalyst component according to the weight of the formula, stir in the mixer for 3 minutes until uniform, and set aside; then put the phosphogypsum The components are weighed in parts by weight and poured into a gravity-free mixer, and the uniformly stirred PH regulator component, water-retaining agent component, modifier component, retarder component and photocatalyst component are added. Stir together with the phosphogypsum component in a mixer for 3 minutes; finally add the lightweight aggregate compo...

Embodiment 2

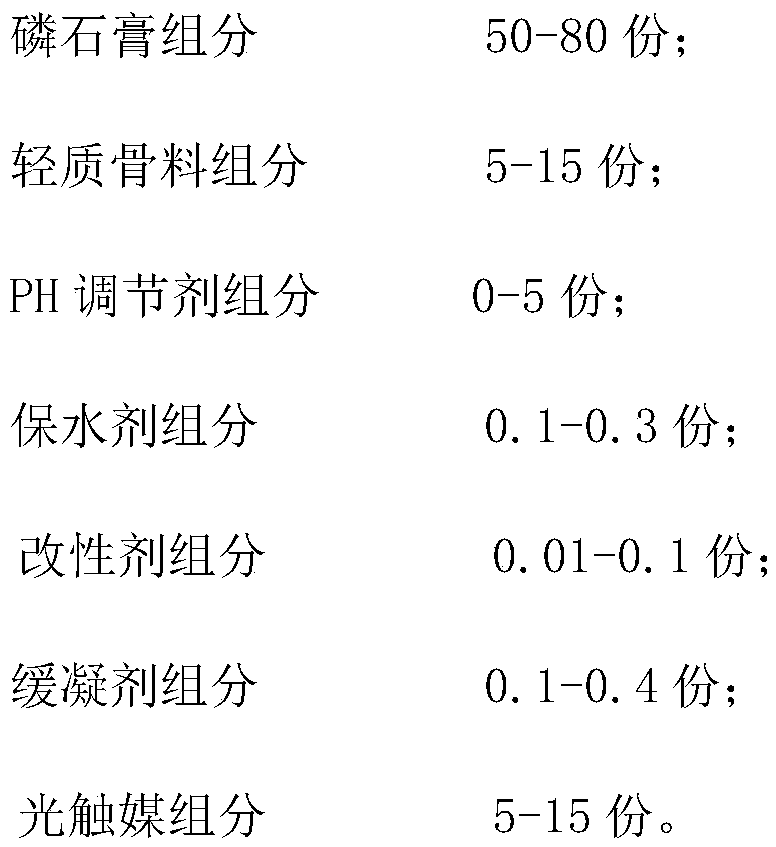

[0022] The formaldehyde-removing plastering gypsum provided in this embodiment includes a phosphogypsum component, a lightweight aggregate component, a pH regulator component, a water-retaining agent component, a modifier component, a set retarder component, and a photocatalyst component , each component is calculated in parts by weight:

[0023]

[0024] First weigh the PH regulator component, water retaining agent component, modifier component, retarder component and photocatalyst component according to the weight of the formula, stir in the mixer for 3 minutes until uniform, and set aside; then put the phosphogypsum The components are weighed in parts by weight and poured into a gravity-free mixer, and the uniformly stirred PH regulator component, water-retaining agent component, modifier component, retarder component and photocatalyst component are added. Stir together with the phosphogypsum component in a mixer for 3 minutes; finally add the lightweight aggregate compo...

Embodiment 3

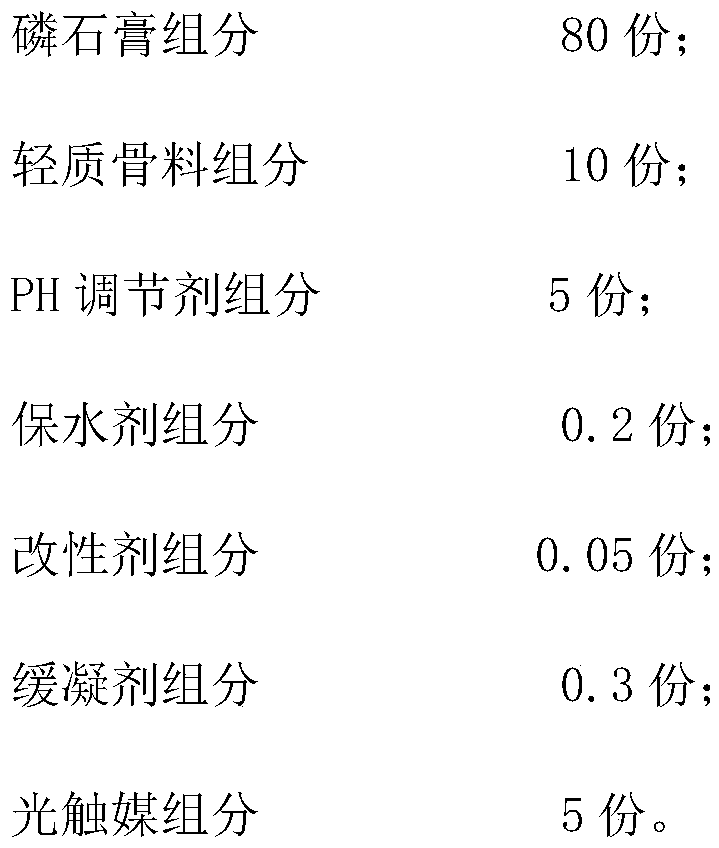

[0026] The formaldehyde-removing plastering gypsum provided in this embodiment includes a phosphogypsum component, a lightweight aggregate component, a pH regulator component, a water-retaining agent component, a modifier component, a set retarder component, and a photocatalyst component , each component is calculated in parts by weight:

[0027]

[0028] First weigh the PH regulator component, water retaining agent component, modifier component, retarder component and photocatalyst component according to the weight of the formula, stir in the mixer for 3 minutes until uniform, and set aside; then put the phosphogypsum The components are weighed in parts by weight and poured into a gravity-free mixer, and the uniformly stirred PH regulator component, water-retaining agent component, modifier component, retarder component and photocatalyst component are added. Stir together with the phosphogypsum component in a mixer for 3 minutes; finally add the lightweight aggregate compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com