Benzaldehyde preparation method

A technology of benzaldehyde and cinnamaldehyde, which is applied in the field of preparation of natural benzaldehyde, can solve the problems such as difficult contact of reactants, unfavorable maintenance of p-benzaldehyde, increase in processing cost, etc., and achieves no effect on naturalness, easy operation, and processing capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

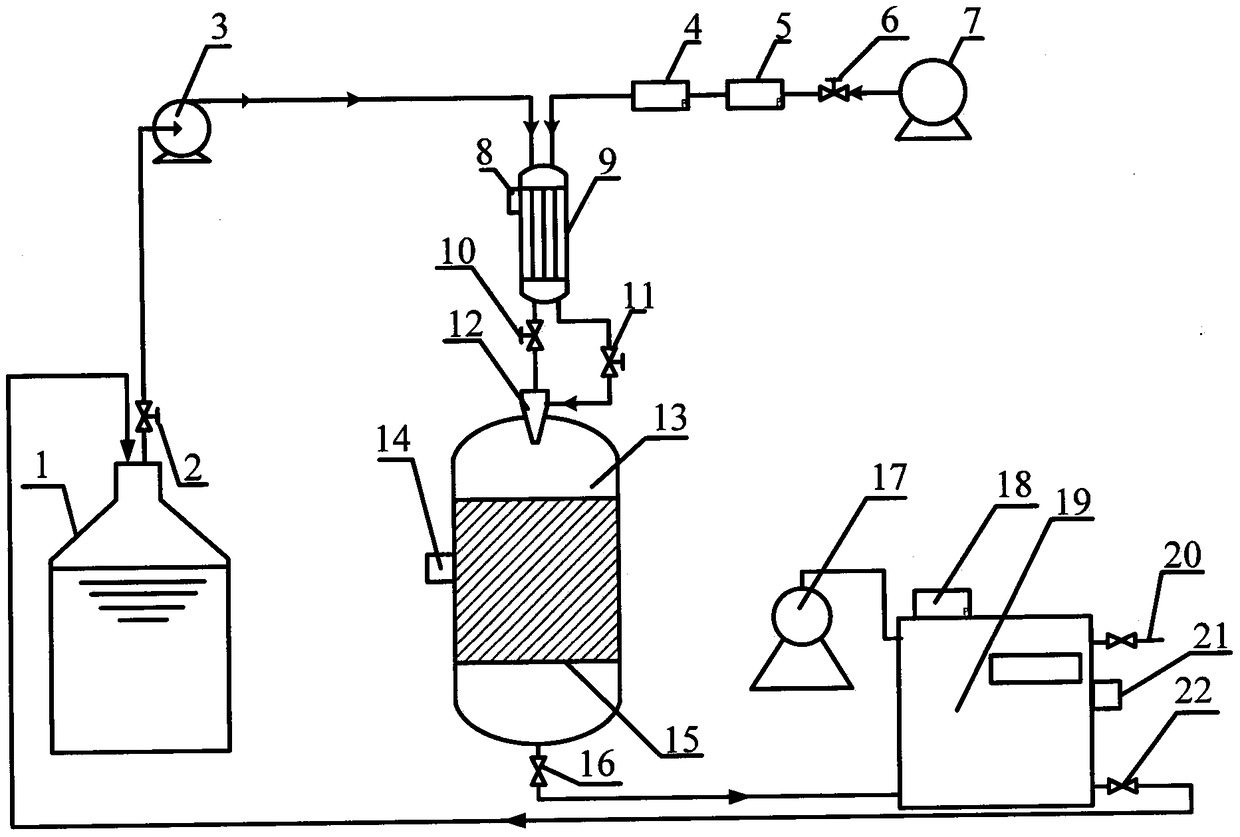

Method used

Image

Examples

Embodiment 1

[0029] Weigh 1.0g V oxide catalyst and put it into a fixed-bed reactor, heat the fixed-bed temperature to 120°C, and pass the cinnamaldehyde with a content of more than 95wt% through a heating device at 120°C at a flow rate of 0.05mL / min, in the mist Mix it with 5 atmospheres of air or oxidation at a flow rate of 50mL / min heated at 120°C in the atomization nozzle, spray it into a fixed-bed reactor after atomization, and carry out the catalytic oxidation reaction of cinnamaldehyde to obtain crude benzaldehyde.

[0030] Under the conditions of 60° C. and 100 Pa, the above crude benzaldehyde was subjected to molecular distillation, and the yield of natural benzaldehyde with a content greater than 98% was obtained after the reaction was stable was 22%.

Embodiment 2

[0032] Weigh 1.0g of Ba oxide catalyst and put it into a fixed-bed reactor, heat the fixed-bed temperature to 150°C, and put cinnamaldehyde with a content of more than 95wt% through a heating device at 150°C at a flow rate of 1.0mL / min. Mix it with 5 atmospheric pressure air or oxidation at a flow rate of 150mL / min heated at 150°C in the atomization nozzle, spray it into a fixed-bed reactor after atomization, and carry out the catalytic oxidation reaction of cinnamaldehyde to obtain crude benzaldehyde.

[0033] Under the conditions of 60° C. and 100 Pa, the above-mentioned crude benzaldehyde was subjected to molecular distillation, and the yield of natural benzaldehyde with a content greater than 98% was obtained after the reaction was stable was 36%.

Embodiment 3

[0035] Weigh 1.0g Mg-V oxide catalyst and put it into a fixed bed reactor, heat the fixed bed temperature to 150°C, and pass the cinnamaldehyde with a content of more than 95wt% through a heating device at 150°C at a flow rate of 1.0mL / min, In the atomizing nozzle, it is mixed with 5 atmospheres of air or oxidation at a flow rate of 150mL / min heated at 150°C, sprayed into a fixed-bed reactor after atomization, and cinnamaldehyde is catalytically oxidized to obtain crude benzaldehyde.

[0036] Under the conditions of 60° C. and 100 Pa, the above-mentioned crude benzaldehyde was subjected to molecular distillation, and the yield of natural benzaldehyde with a content greater than 98% was obtained after the reaction was stable was 36%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com