Device for continuous production of melamine-formaldehyde resin

A technology of melamine and formaldehyde resin, applied in the directions of transportation and packaging, mixers, mixer accessories, etc., can solve the problems of discontinuity in the preparation process of melamine resin, and achieve the effects of good product quality, less land occupation, and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

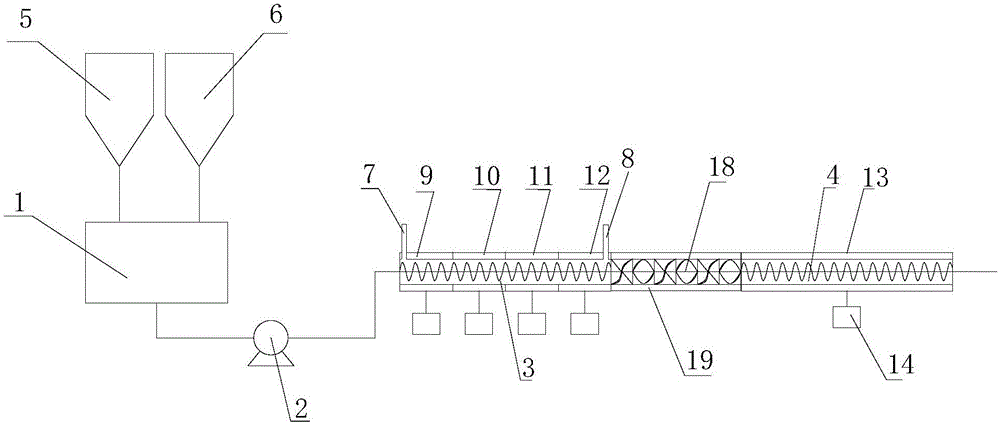

[0026] Such as figure 1 As shown, the present embodiment provides a device for continuous production of melamine formaldehyde resin, comprising a mixture silo 1, a material pump 2, a first screw machine 3, a static mixer 18 and a second screw machine 4 connected in sequence, and the mixture silo 1 is respectively connected with the melamine high level bin 5 and the paraformaldehyde high level bin 6, the feeding place of the first screw machine 3 is provided with a lye feed port 7, and the end of the first screw is provided with an auxiliary material feed port 8. When adopting this embodiment to prepare melamine resin, melamine is powder, paraformaldehyde is granular material, and the solvent of reaction is the lye added at the feeding place of the first screw machine 3, wherein, lye is that the mass ratio is 0.2 ~0.5% aqueous solution of organic or inorganic base. The auxiliary materials added are one or more inorganic sodium salts. With the equipment of this embodiment, pow...

Embodiment 2

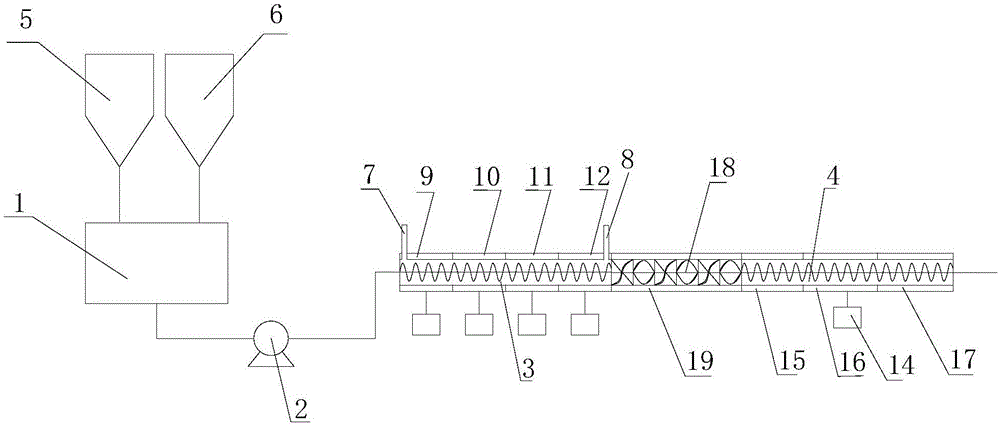

[0034] Such as figure 2 As shown, the present embodiment provides a device for continuously producing melamine formaldehyde resin. In the present embodiment, the sixth jacket 15, the seventh jacket 16 and the eighth jacket 17 are respectively arranged outside the second screw machine, They are respectively connected to the mold temperature machine, the preset temperature of the mold temperature machine connected to the sixth jacket 15 is 100-90°C, and the preset temperature of the mold temperature machine 14 connected to the seventh jacket 17 is 90°C. ~80°C, the preset temperature of the mold temperature machine connected to the eighth jacket 18 is 80~70°C.

[0035] Other structures of the device for continuously producing melamine-formaldehyde resin in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com