Apparatus and method to co-produce formaldehyde and UFC (urea-formaldehyde concentrate) by iron-molybdenum process

A formaldehyde, iron and molybdenum technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carbon-based compounds, etc., can solve the problems of unstable domestic process technology, large one-time investment, high investment, and prolong the continuous operation period. , Increase the absorption efficiency, the effect of not easy to pulverize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

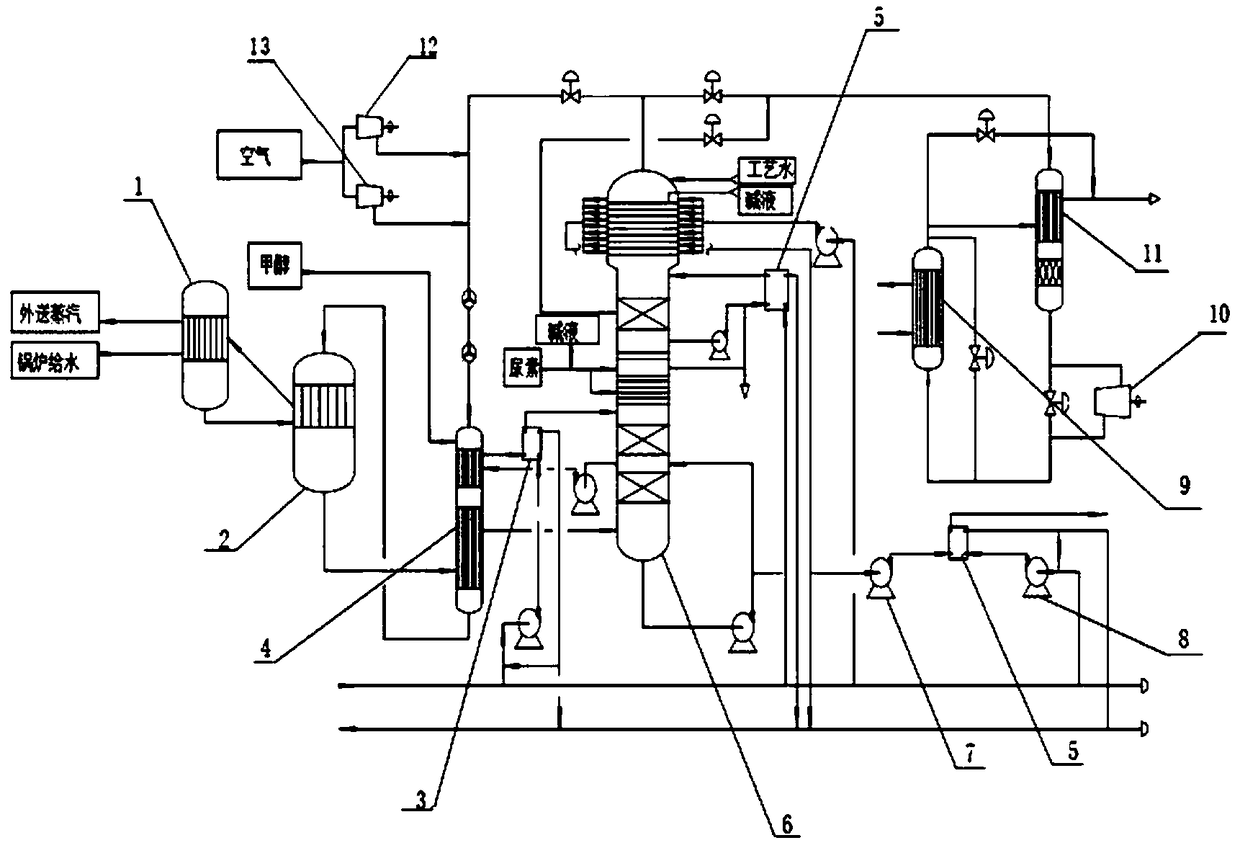

[0030] like figure 1 Shown, a kind of iron-molybdenum method produces the device of formaldehyde co-production UFC, comprises methanol evaporator 4, methanol oxidizer 2 and absorption tower 6, the input end of methanol evaporator 4 is provided with methanol feed port and air feed port, The output end is connected to the input end of the methanol oxidizer 2, and the formaldehyde generated after the reaction of the mixed gas of methanol and air in the methanol oxidizer 2 enters the absorption tower 6 through the methanol evaporator 2 and the plate heat exchanger 3, and the absorption tower 6 is set There are urea feed port and lye feed port. A heat transfer oil condenser 1 is arranged on the methanol oxidizer 2 . The lye feed inlet is arranged at the top and the middle of the absorption tower 6 , and the urea feed inlet is arranged at the middle of the absorption tower 6 . The iron-molybdenum catalyst in the methanol oxidizer 2 has a cylindrical structure.

[0031] The method...

Embodiment 2

[0039] Embodiment 2: This embodiment produces the formaldehyde solution of 37-55% concentration and 85 concentration UFC urea-formaldehyde pre-condensed solution co-production.

[0040] The difference between this embodiment and embodiment 1 is that the mixture of urea and lye is put into the absorption tower according to the ratio, and the urea and formaldehyde solution react in the absorption tower to form UFC urea-formaldehyde pre-condensed liquid. Add urea and lye through the urea feed port and lye feed port, and the urea and formaldehyde solution react in the absorption tower to obtain urea-formaldehyde pre-condensed liquid UFC. The function of lye is to adjust the pH value of the system.

[0041] The iron-molybdenum method formaldehyde co-production UFC process device provided by the present invention has high conversion rate of methanol raw material, high specification of output steam, low consumption, long service life of catalyst, mild reaction conditions, and can meet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com