Method for treating methanol and formaldehyde industrial wastewater by electrocatalytic oxidation

A technology for electrocatalytic oxidation and industrial wastewater, applied in chemical instruments and methods, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. Formaldehyde wastewater treatment difficulty and other issues, to achieve the effect of low cost, stable properties, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

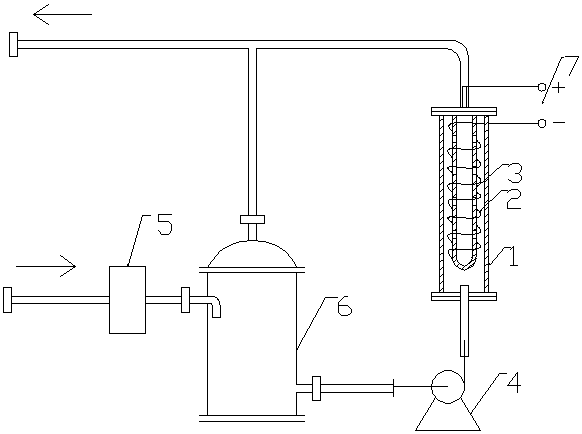

Image

Examples

Embodiment 1

[0026] (1) Etch the porous titanium tube with an outer diameter of 30 mm, a thickness of 2.5 mm, and a length of 200-1000 mm with a mixed solution of acid and alcohol, take it out, ultrasonically clean it, dry it in an oven, and set it aside;

[0027] (2) The germanium bismuth lanthanum coated electrode was prepared by impregnation and coating pyrolysis method. An electrode coating solution A of Ge:Bi:La=100:X:Y (molar ratio) is prepared with a low-carbon alcohol solution as a solvent, wherein the value of X is 1-40, and the value of Y is 1-15. Immerse the etched porous titanium tube in solution A for 1.6 minutes at room temperature, dry the surface solvent in an oven, and calcinate in a heating furnace at 300-500°C for 60 minutes; repeat 5 times;

[0028] (3) Loading TiO by sol-gel method 2 The substrate is the cathode, and a low-carbon alcohol solution is used as the solvent to add a titanium source to prepare a uniform and transparent sol, and then brush coating and therma...

Embodiment 2

[0040] (1) The porous titanium tube with an outer diameter of 30 mm, a thickness of 2.5 mm, and a length of 200-1000 mm is etched with a mixed solution of acid and alcohol, taken out, ultrasonically cleaned, dried in an oven, and set aside;

[0041] (2) The germanium bismuth lanthanum coated electrode was prepared by impregnation method and coating pyrolysis method. Using low-carbon alcohol solution as a solvent, prepare electrode coating solution A with Ge:Bi:La=100:X:Y (molar ratio), wherein the value of X is 1-40, and the value of Y is 1-15. Immerse the etched titanium film substrate in the above-prepared solution A, immerse at room temperature for 1 min, dry the surface solvent in an oven, and calcinate in a heating furnace at 300-500 ° C for 60 min; repeat 5 times;

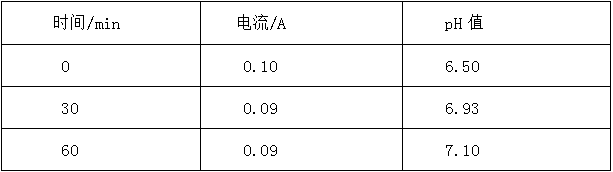

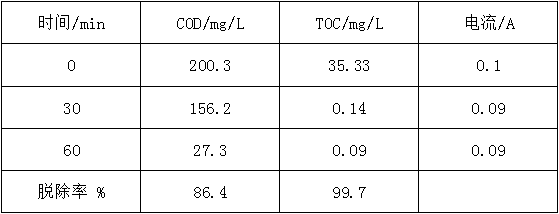

[0042] (3) The electrode prepared by the above process is used to electrochemically treat wastewater containing methanol and formaldehyde. The anode is the above-mentioned porous titanium-based catalytic acti...

Embodiment 3

[0048] (1) The porous titanium mesh with a length of 8-10 cm, a width of 8-10 cm, and a thickness of 2.5 mm was etched in a constant temperature water bath with a mixed solution of acid and alcohol for a certain period of time, and then ultrasonically cleaned after taking it out, and carried out in an oven. dry, ready for use;

[0049] (2) The nickel-cobalt coated electrode was prepared by impregnation method and coating pyrolysis method. Using low-carbon alcohol as a solvent, prepare electrode coating solution B with Ni:Co=90:Z (molar ratio), where Z value is 1-20. Soak the etched porous titanium mesh in the above preparation solution B, soak for 2 minutes at room temperature, dry the surface solvent in an oven, and calcinate in a heating furnace at 400°C for 60 minutes; repeat 5 times;

[0050] (3) Use the electrode prepared by the above process to electrochemically treat wastewater containing methanol and formaldehyde. The anode is a porous titanium-based catalytic active ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com