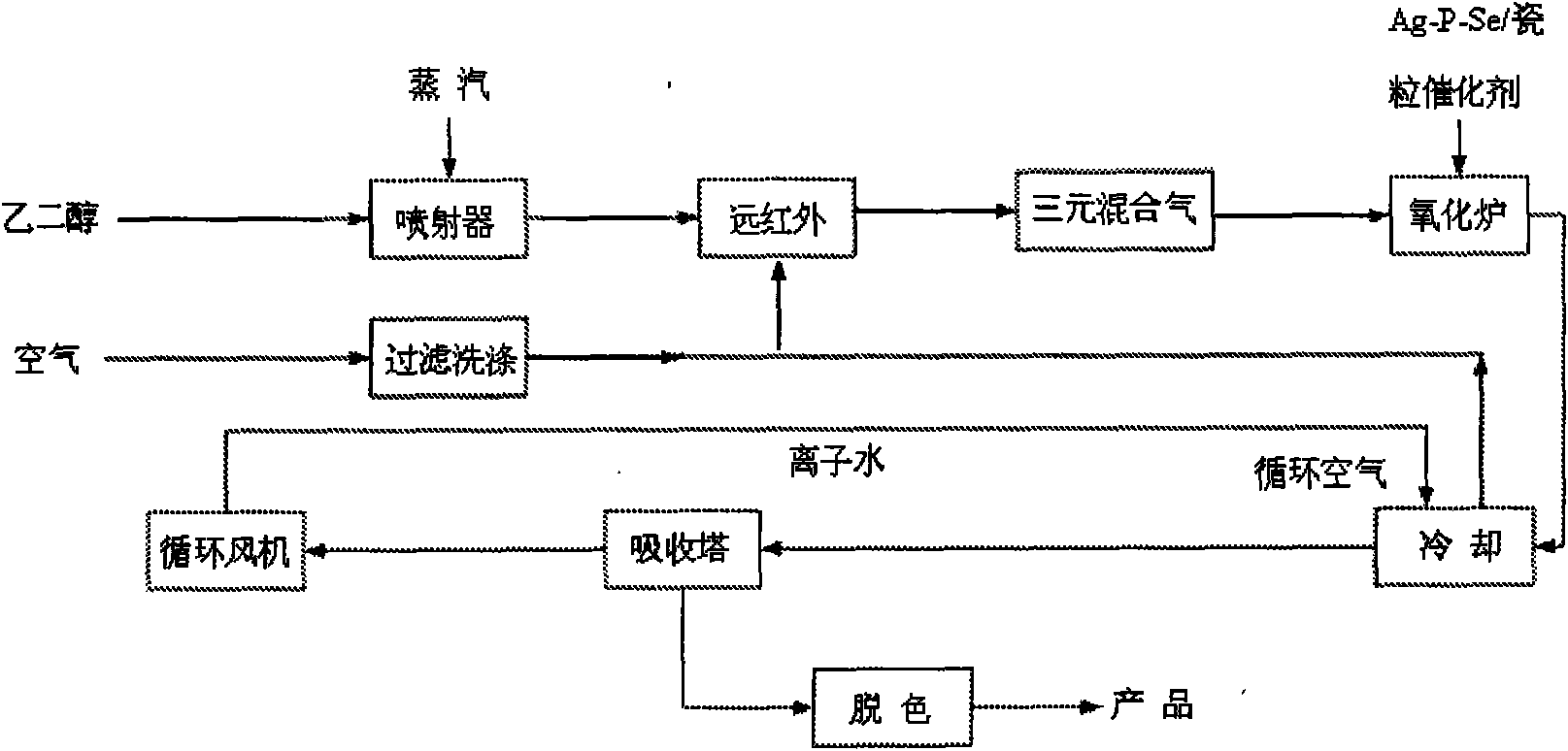

New process for producing glyoxal by using complex silver catalyst to oxidize glycol

A catalytic oxidation and ethylene glycol technology, applied in the preparation of organic compounds, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of oxidation furnace components that cannot meet large-scale production, short catalyst life, low catalyst activity and selectivity and other problems, to achieve the effect of low cost, less generation, and lower bed resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

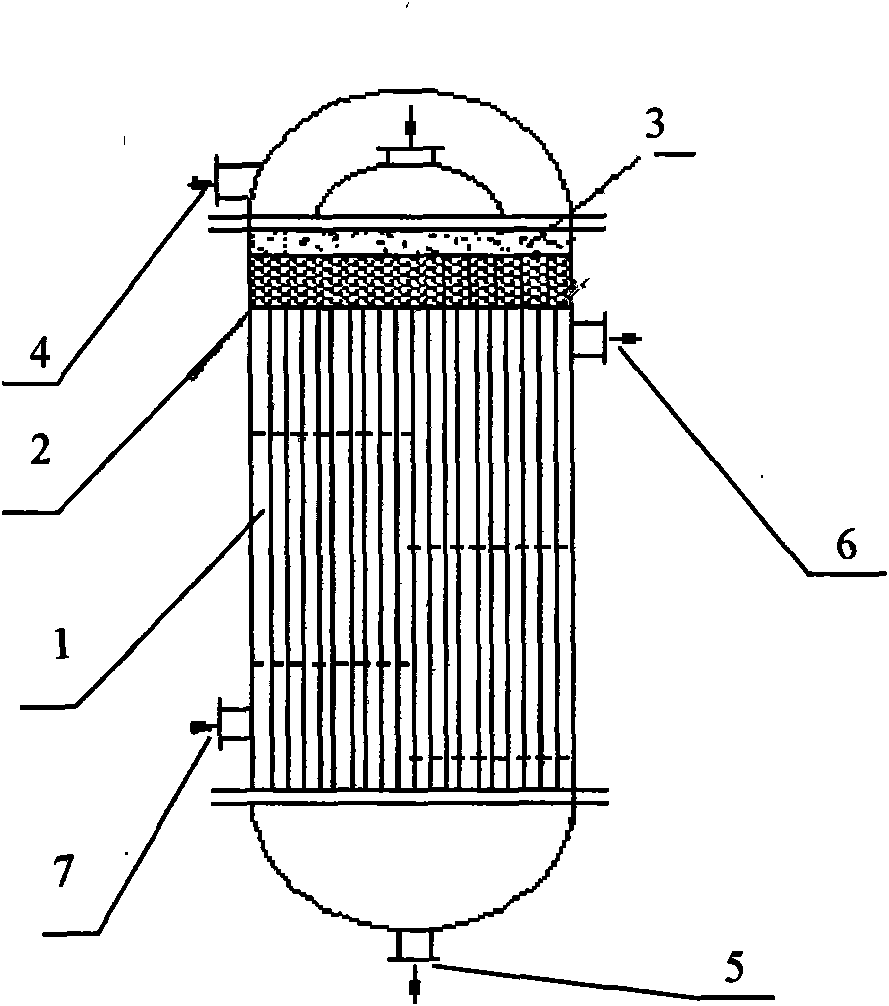

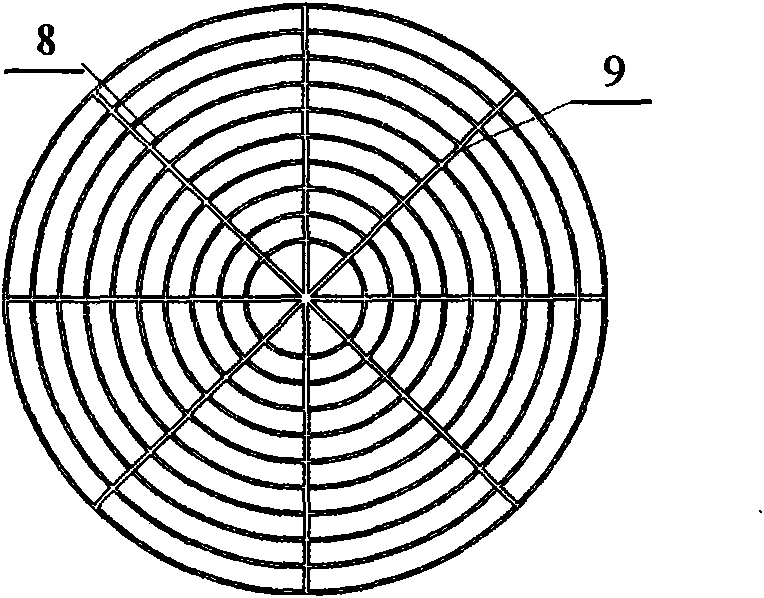

[0017] Embodiment 1: The purification and impurity removal device before the oxidation furnace in the traditional production process equipment is removed, and the oxidation furnace is converted into a grid plate oxidation furnace integrating the purification and removal device, such as figure 2 , image 3 As shown, the oxidation furnace is composed of a heat exchanger, a grid support plate, a feed inlet and a discharge outlet. The upper and lower side walls of the heat exchanger 1 are respectively provided with a heat exchange medium outlet 6 and an inlet 7, and above it A grid-type support plate 2 is provided, and the support plate is covered with a composite silver catalyst, and a purifying and impurity-removing agent 3 is laid on the catalyst layer; The feed port 4 is connected to the discharge port of the ternary mixer through a pipe guide, and the discharge port 5 is connected to the cooling device.

[0018] Direct spraying of high-pressure steam, combined with far-infr...

Embodiment 2

[0019] Embodiment 2: except adopting Ag-P-Se / ceramic particle catalyst (ceramic particle accounts for 60% of catalyzer gross weight), other reaction conditions are with embodiment 1, the yield 72.0% of glyoxal, the selection of glyoxal Sex 78.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com