Method and device for cyclone purification of coolant in boron removal section of boron recovery system

A recovery system and coolant technology, applied in chemical instruments and methods, separation methods, radioactive purification, etc., can solve problems such as desolidification of coolant in the boron removal section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Cyclone purification process for coolant in boron removal section of boron recovery system

[0054] 1. Implementation process

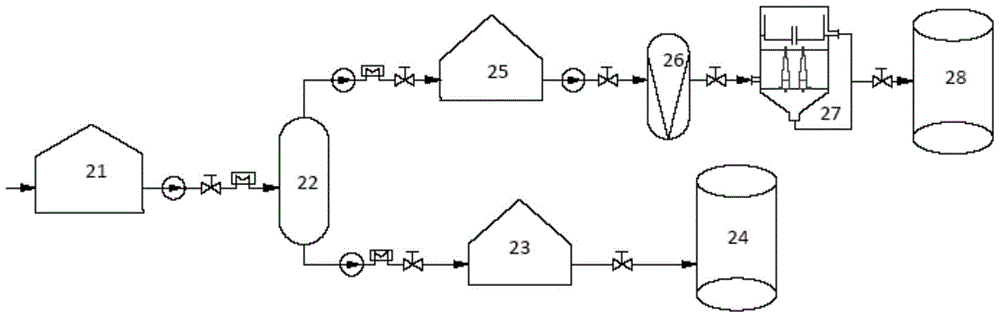

[0055] Such as figure 2 shown.

[0056] 2. Key equipment

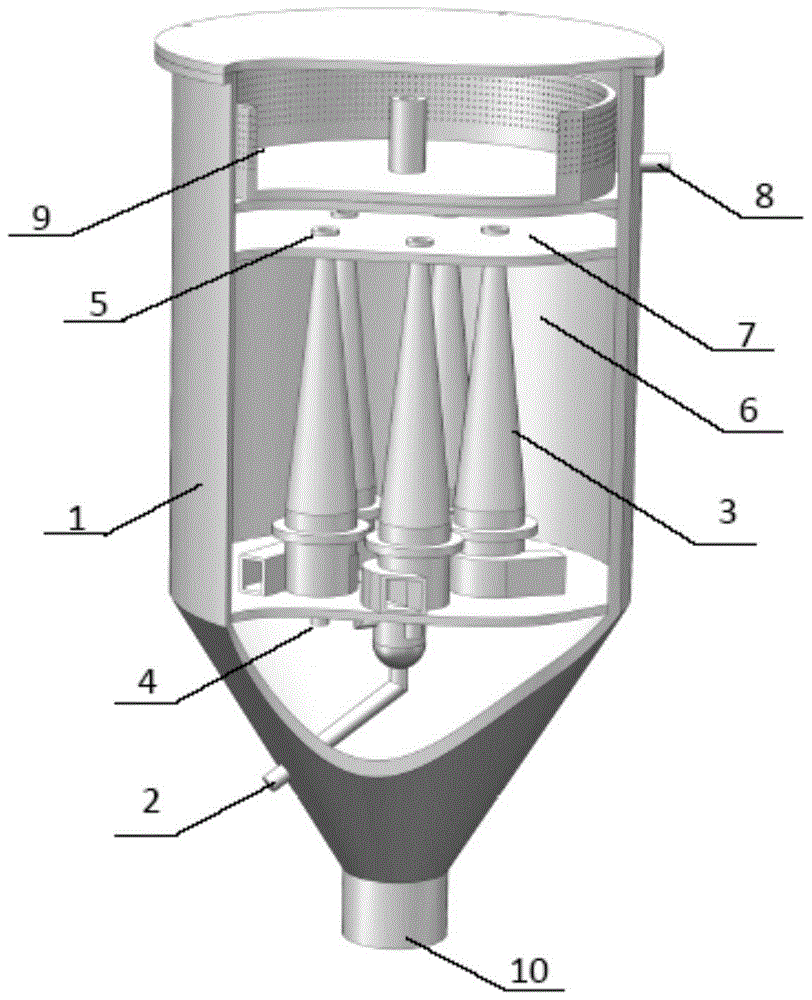

[0057] The complete set of separation device combined with micro-cyclone core tube assembly and filter ash hopper is the key equipment in this process. Among them, the core tube assembly of the vertical micro-cyclone is placed in the shell of the separation device, and the filter ash hopper is placed on the top of the micro-cyclone separation device to connect the bottom flow of the micro-cyclone. The processing capacity of the equipment is 10m 3 / h, the external dimension is Φ600×2400. The top is closed with a tube plate type, and the movable ash hopper is used to facilitate the subsequent replacement of the ash hopper.

[0058] 3. Running results

[0059] The density of the dispersed phase used in the experiment is 1.16g / cm 3 , Concentration of 10ppm containing resin partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com