Setting method of nuclear level indicator for pressure vessel

A pressure vessel and material level gauge technology, which is applied in the field of nuclear material level gauges for pressure vessels, can solve the problems of difficulty in relieving local peak stress at the outer edge of openings, difficulty in tightly fitting welded pipes, and strong radiation safety risks, etc. Achieve the effect of simple and reliable setup, simple manufacturing, and improved fatigue and creep failure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

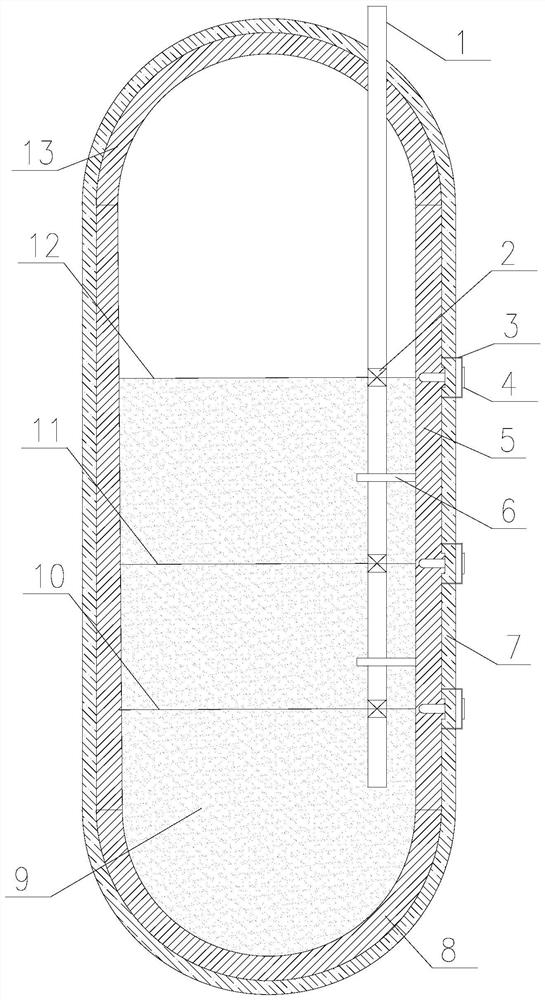

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] combine figure 1 and figure 2 , the nuclear level gauge setting method for the pressure vessel provided by the present invention comprises the following steps:

[0033] 1) Determine the installation position of the nuclear material level gauge on the pressure vessel according to the minimum operating material level 10, the normal operating material level 11 and the highest operating material level 12 of the material 9 in the pressure vessel;

[0034] 2) According to the installation position of the nuclear material level gauge, determine the installation sequence of the components of the nuclear material level gauge as follows:

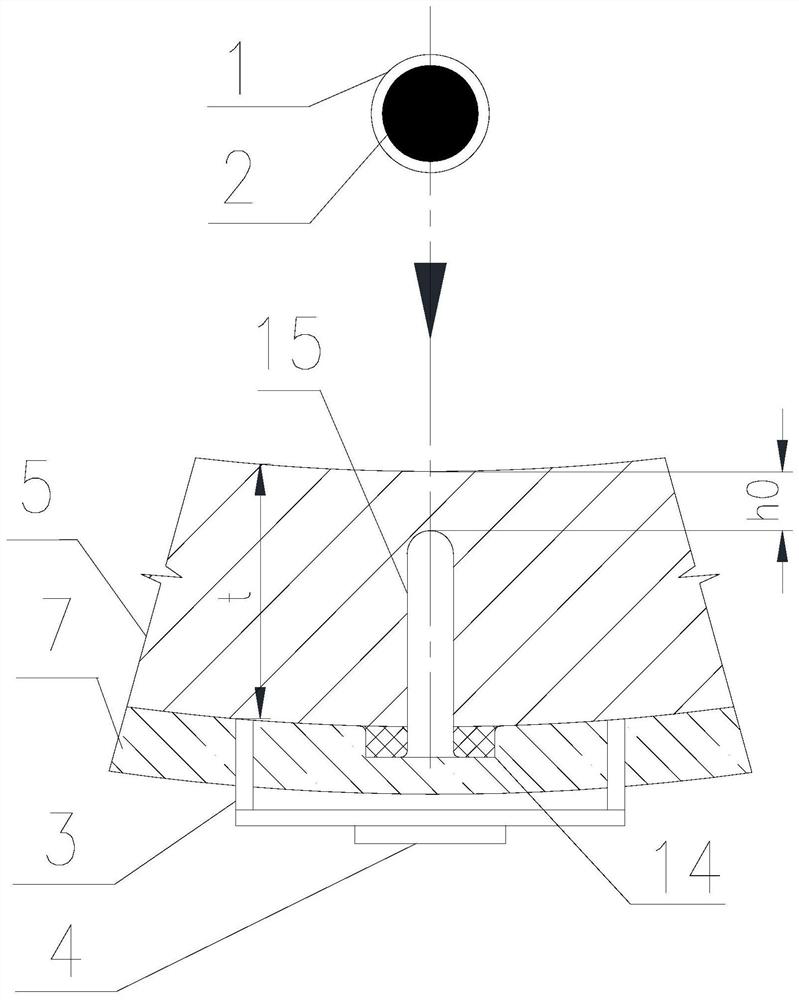

[0035] a. Install the built-in nuclear source bushing: the built-in nuclear source bushing 1 is generally inserted into the inside of the pressure vessel cylinder 5 from the upper head 13 of the pressure vessel, close to the bottom o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com