Method for cladding surface of micro-nano-copper ball with thick tin layer with weldable thickness

A weldability, micro-nano technology, applied in coatings and other directions, can solve the problems of high weld porosity and low connection strength, and achieve the effects of simple processing technology, low cost and simple material conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

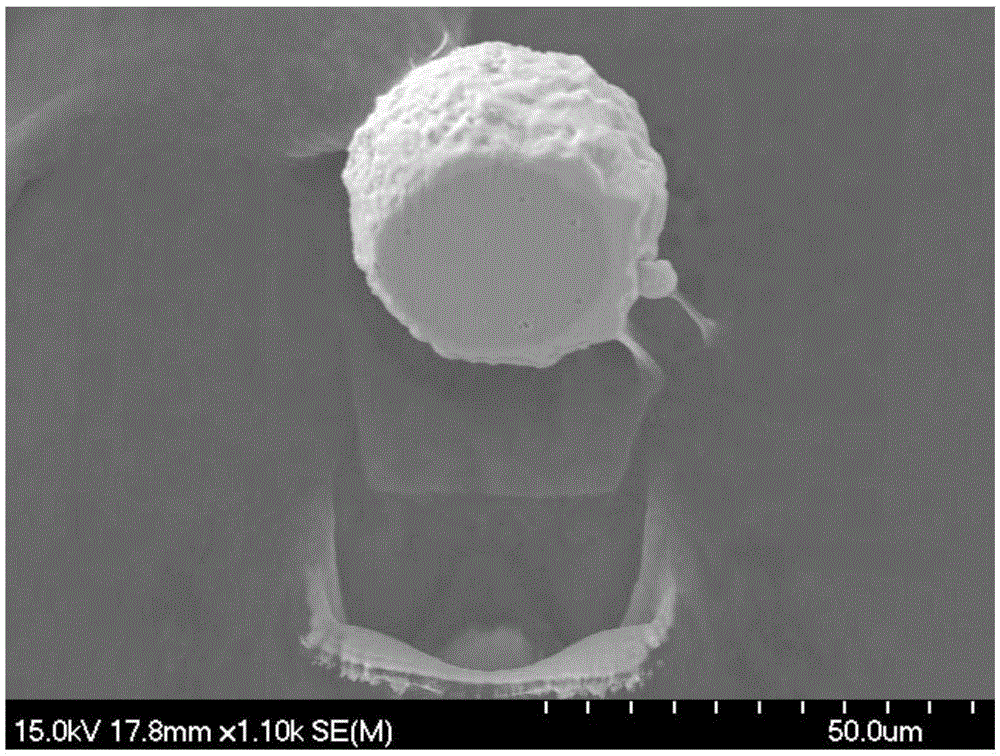

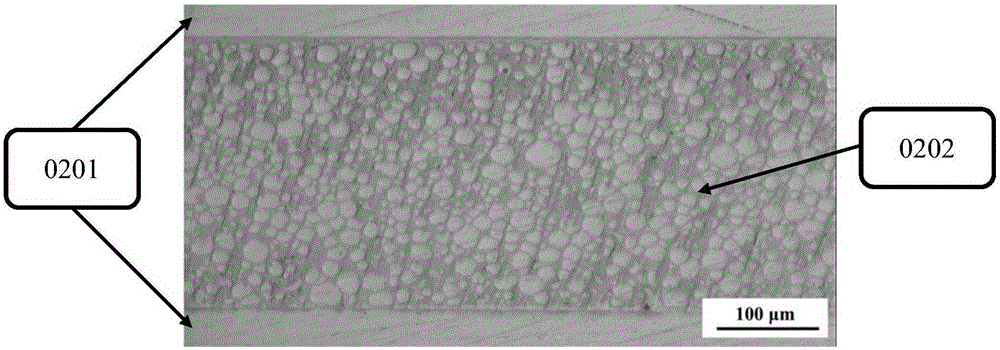

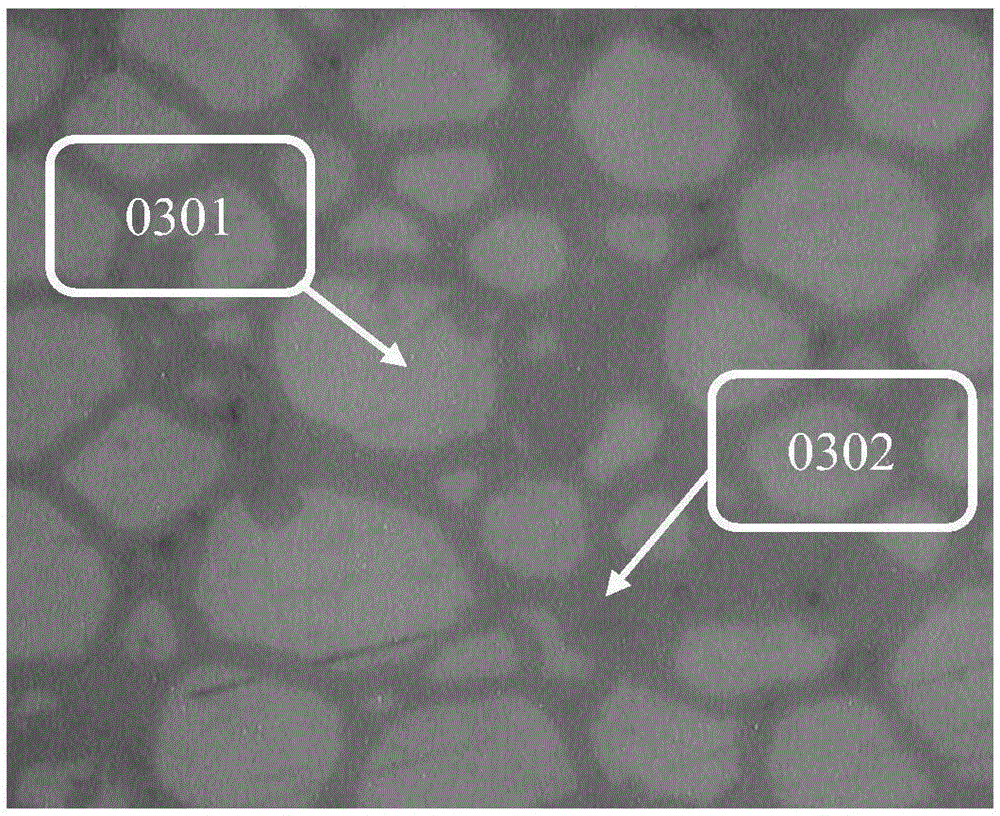

[0057] Implementation example 1, refer to figure 1 , 2 and 3:

[0058] Based on the above considerations, through a large number of experimental attempts and data analysis, we invented the plating method for plating the surface of micro-nano copper balls with a solderable thick tin layer. The purpose of plating a thick tin layer on the surface of the copper ball.

[0059]The method specifically includes the following steps (using 50ml of plating solution to tinplate 4g of copper powder with a particle size of 30 μm and finally making it into a high-temperature-resistant solder joint as an example):

[0060] (1), weigh 3.7g of sodium hypophosphite, 5g of thiourea, 0.02g of hydroquinone, 0.04g of ethylenediaminetetraacetic acid, dissolve in 50ml of deionized water and apply stirring at a stirring rate of 100rpm, add methanesulfonic acid 0.4g, 0.7ml of ethylene glycol, put the solution in a water bath and heat to 80°C until the solute is completely dissolved to obtain solution...

Embodiment 2

[0071] Implementation example 2, refer to figure 1 , 2 and 3:

[0072] In order to verify that this formula has an excellent coating effect on thick tin layers with solderability for copper powders of various particle sizes, we specially selected copper powders with a particle size of 1 μm for tin plating, and finally tinned the copper powder with a particle size of 1 The micron CuSn core-shell copper powder is prepared into a pre-chip for actual welding to obtain solder joints that can withstand high temperature service.

[0073] The method specifically includes the following steps (using 100ml of plating solution to tinplate 8g of copper powder with a particle size of 1 μm and finally making it into a high-temperature-resistant solder joint as an example):

[0074] (1), Weigh 7.4g of sodium hypophosphite, 10g of thiourea, 0.04g of hydroquinone, 0.08g of ethylenediaminetetraacetic acid, dissolve in 100ml of deionized water and apply stirring at a stirring rate of 100rpm, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com