Automatic abrasive quantity detection system and pre-mixed abrasive water-jet numerical-control cutting machine

An automatic detection and abrasive technology, which is applied in the direction of abrasive jet machine tools, abrasive feeding devices, abrasives, etc., can solve the problems of inability to judge abrasive reserves, sand accumulation in side pipes, and damaged workpieces, etc., and achieve a wide range of application and popularization and application Foreground, guarantee cutting quality, improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

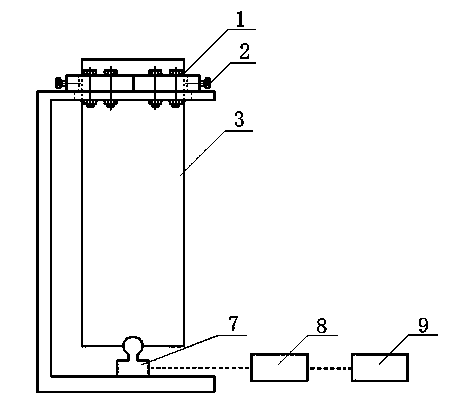

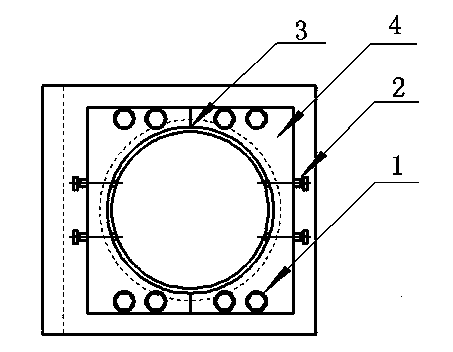

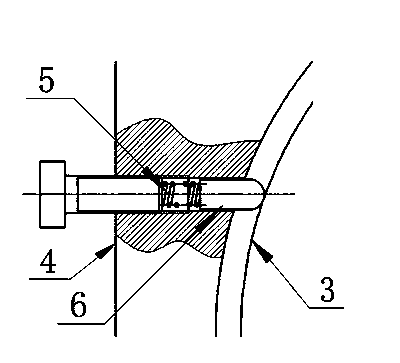

[0019] Such as figure 1 As shown, the abrasive amount automatic detection system of the present invention includes a bracket, a high-pressure abrasive tank 3 for loading water and abrasives, a fixing device 4, and a single-point load cell 7, a numerical control circuit 8, and a host computer 9 that are electrically connected in sequence . The high-pressure abrasive tank 3 is placed vertically, its upper part is set on the top of the bracket, and its bottom center is provided with an inwardly protruding spherical groove. The bottom surface of the single-point load cell 7 is fixed on the bottom of the bracket, and its top is located in the spherical groove at the bottom of the high-pressure abrasive tank 3, and the spherical groove matches the spherical convex surface of the single-point load cell 7 to reduce the The angle deviation when the small abrasive pot is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com