Wheat seeder

A technology of a seeder and a seeding mechanism, which is applied to fertilizers and seeding equipment, etc., can solve the problems that the straw cannot be dispersed, it is difficult to ensure the germination rate and survival rate of wheat, and the depth of seed burial is inconsistent, so as to improve the efficiency of sowing work, The germination rate and survival rate guarantee, the effect of improving the germination rate and survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

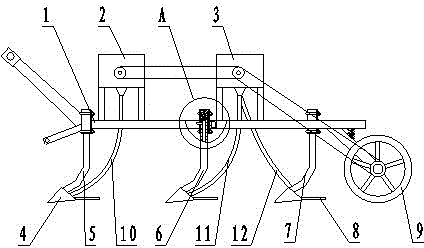

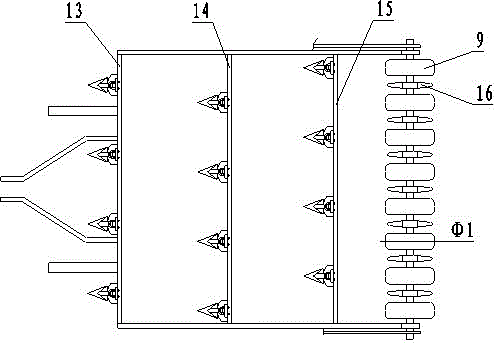

[0017] Refer to Figure 1. image 3 The present invention includes a frame 1, a fertilization mechanism, a seeding mechanism and a compaction mechanism. The frame 1 includes a front beam 13, a middle beam 14 and a rear beam 15, and the fertilization mechanism includes a fertilizer box 2, a fertilizer discharge pipe 10, and a front beam. Columbine leg 5, the sowing mechanism includes a seed box 3, a front row seed tube 11, a rear row seed tube 12, a middle columbine leg 6 and a rear columbine leg 7, the special feature of which is: the front columbine leg 5 and the front beam 13. The middle columbine leg 6 and the middle beam 14, the rear columbine leg 7 and the rear beam 15 are all connected by elastic components. The compaction mechanism includes a set of compaction wheels 9 and a set of dispersers 16, the compaction wheels 9 and The disperser 16 is installed on the same drive shaft, and a disperser 16 is arranged between two adjacent compaction wheels 9.

[0018] See figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com