A high-current cyclotron beam adjustment device and beam adjustment method

A cyclotron and beam technology, applied in DC voltage accelerators, magnetic resonance accelerators, accelerators, etc., can solve the problems of increasing labor costs and resource costs, occupying experimental sites, etc., to avoid construction and maintenance costs, and compact structure Tight, structurally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: A beam debugging target device for a high-current cyclotron, including a fixed frame that can be fixedly installed relative to the ground. The fixed frame replaces the traditional wall structure and is relatively fixedly connected to the ground. When in use, it can be set in a strong The middle of the flow cyclotron and the experimental terminal avoids the defect in the prior art that the debugging device can only be arranged at a fixed position inside the wall, so as to reduce the occupied area.

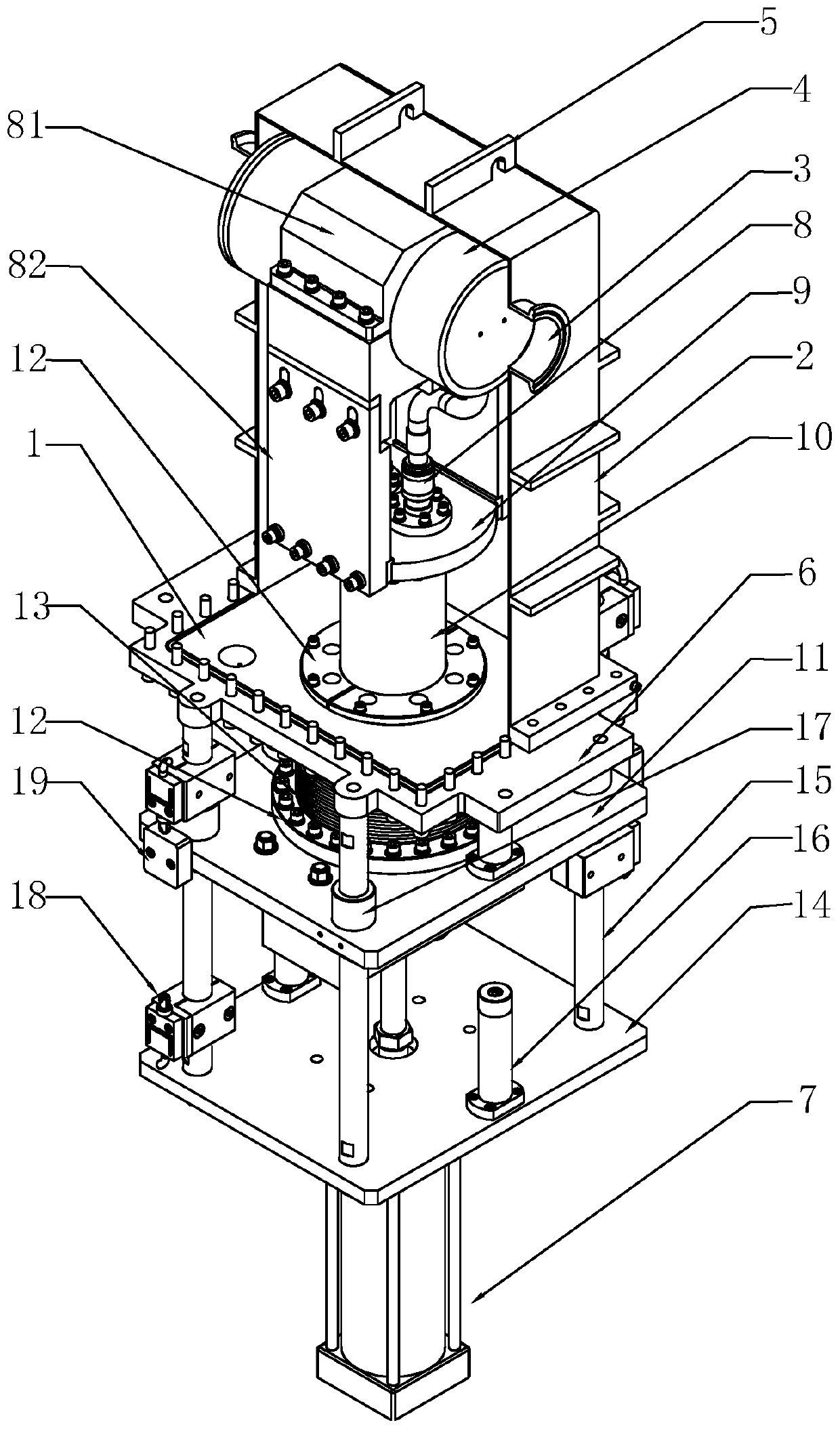

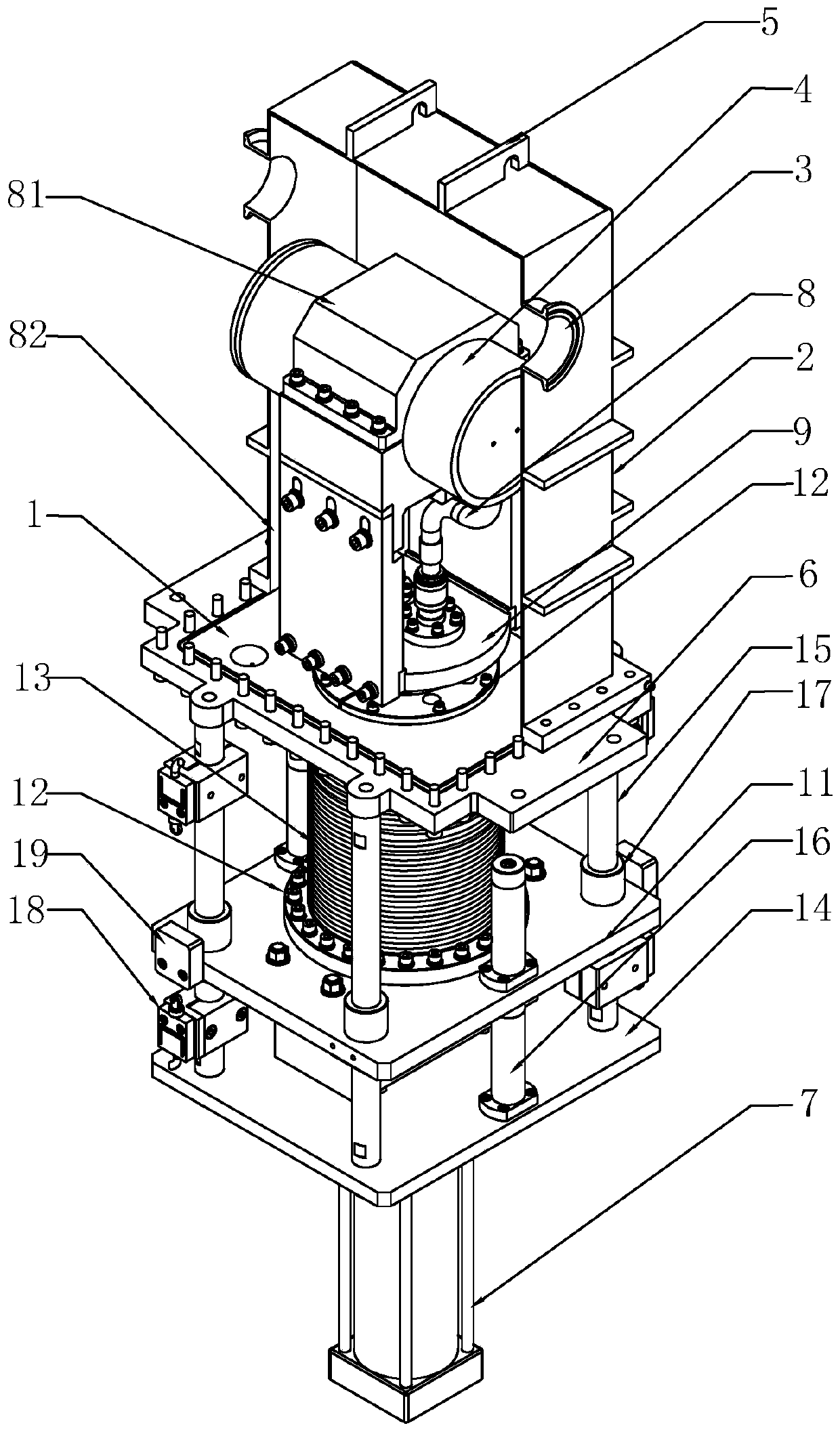

[0041] Such as figure 1 and figure 2 As shown, a first fixed plate 1 is fixedly connected to the fixed frame (not shown in the figure), and a vacuum protection cover 2 is arranged above the first fixed plate 1 (in order to show the structure in the vacuum cover, figure 1 and figure 2 The vacuum protection cover adopts a half-section structure). The vacuum protection cover 2 is provided with a beam channel 3 through which a strong proton beam passes, and a t...

Embodiment 2

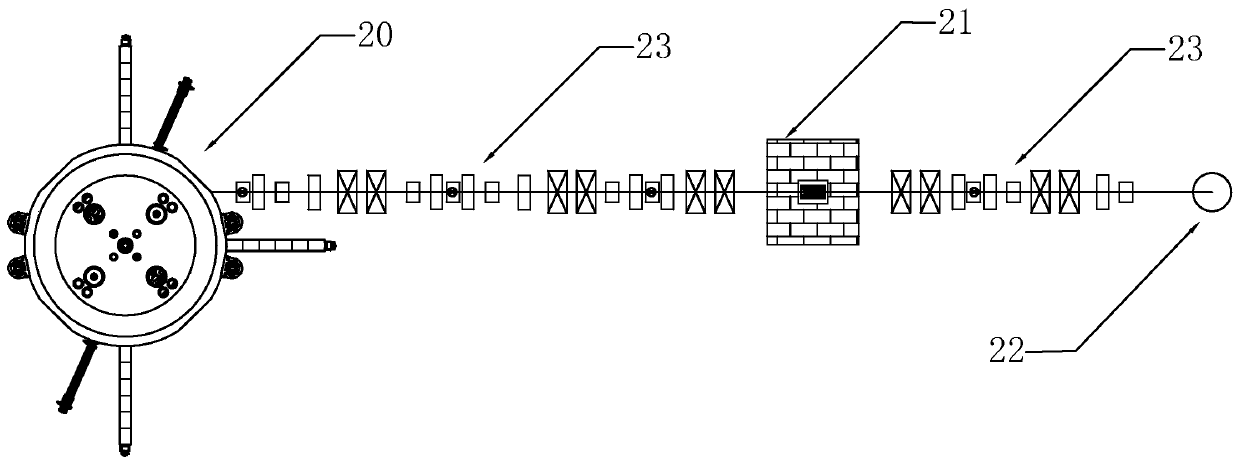

[0055] This embodiment discloses a method for debugging the beam of the high-current cyclotron described above, such as image 3 As shown, the high-current cyclotron beam debugging device 21 in Embodiment 1 is adopted, and the front end of the high-current cyclotron beam debugging device 21 is connected to the high-current cyclotron 20 through a beam vacuum pipeline 23, and the high-current cyclotron The rear end of the cyclotron beam debugging device 21 is connected to the experimental terminal 22 through a beam vacuum pipe 23, and a local shielding mechanism is set outside the high-current cyclotron beam debugging device 21. When it is necessary to perform beam debugging on the high-current cyclotron 20, the remote control starts the cylinder 7 to do the stretching movement, driving the target head 4 to rise to the beam channel 3, and the beam emitted by the high-current cyclotron 20 The streamer light will fall to the target head 4 to realize the beam adjustment process; wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com