Swirl reinforcing method and device for removing hydrogen sulfide by gas

A technology for removing hydrogen sulfide and strengthening the device, which is used in the cyclone removal of heavy hydrocarbon components, H2S, H2S components, and amine-rich components and amine-rich components. Liquid foaming, pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: 45,000 tons / year fuel gas desulfurization unit of the Refining Division of Sinopec Shanghai Gaoqiao Petrochemical Company

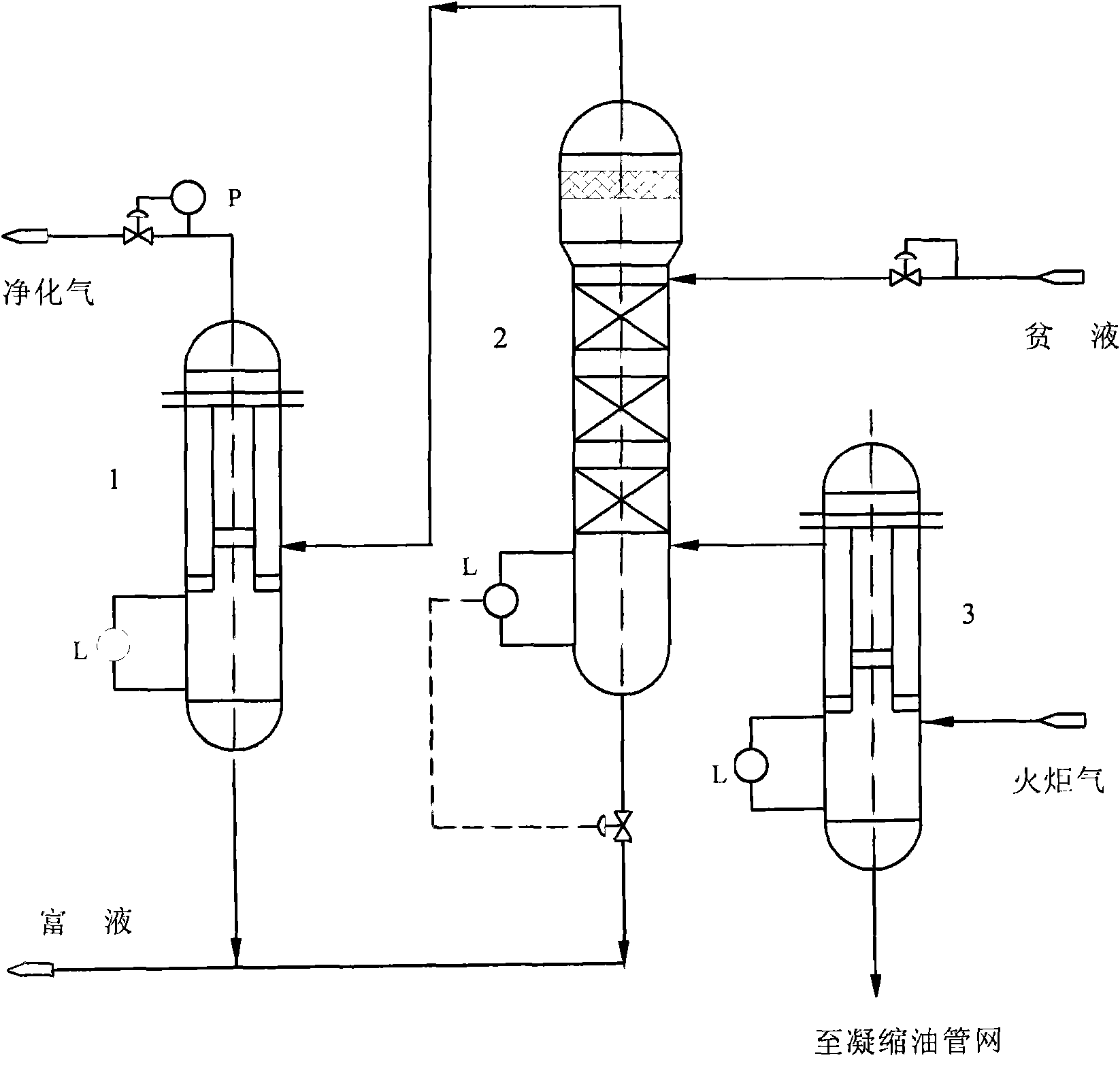

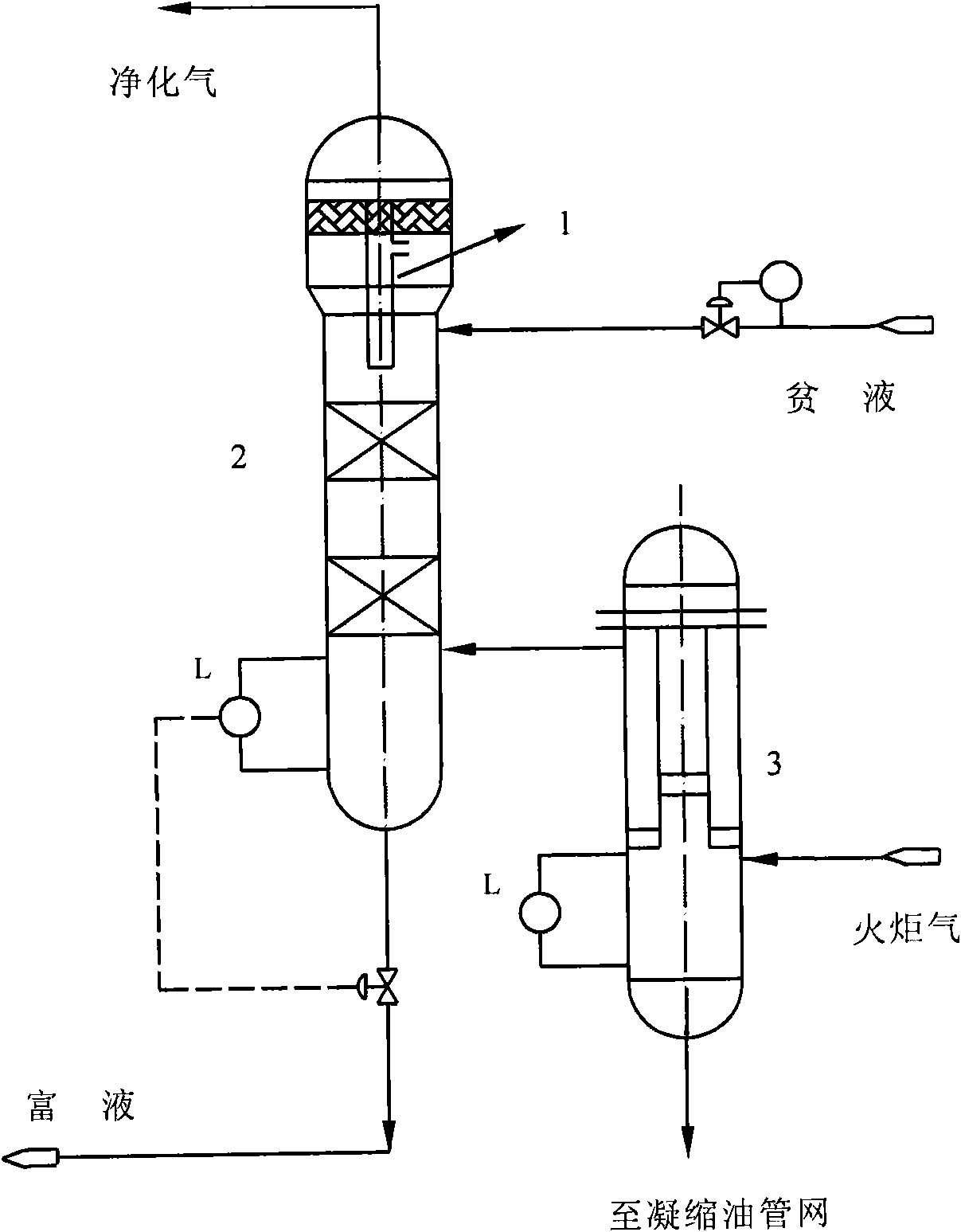

[0051] The Refining Division of Sinopec Shanghai Gaoqiao Petrochemical Company adopts the micro-cyclone separation technology for the 45,000-ton / year fuel gas desulfurization unit. Avoid amine liquid foaming and tray blockage, and avoid amine liquid entrainment in desulfurization gas torch gas. The main equipment includes a desulfurization tower, a cyclone dehydrocarbonizer, and a cyclone deaminator.

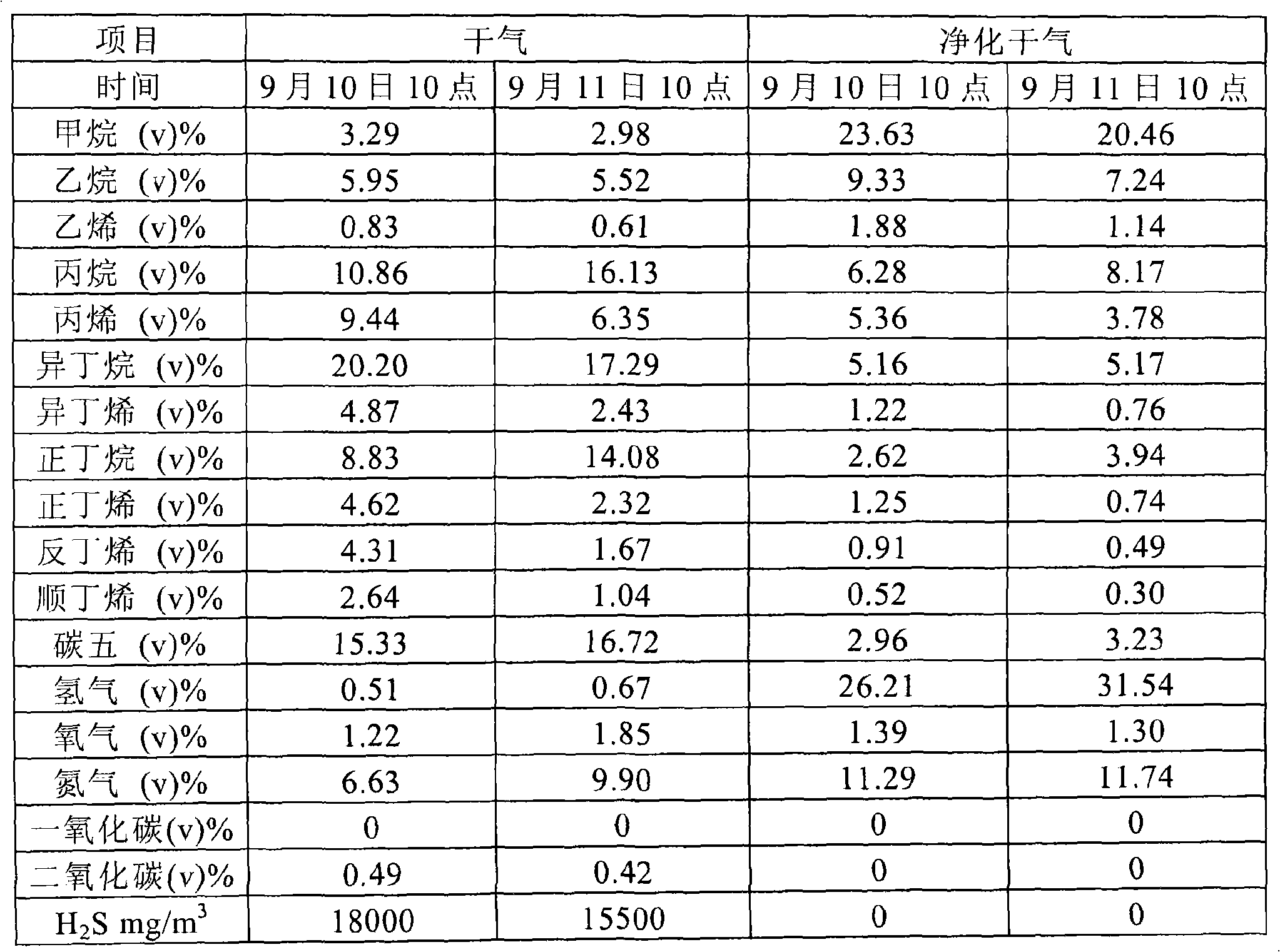

[0052] The equipment has been running continuously and stably since it was put into use in November 2007. The Refining Division of Sinopec Shanghai Gaoqiao Petrochemical Company calibrated the device for a total of 24 hours from 10:00 on September 10, 2008 to 10:00 on September 11, 2008:

[0053] 1. Raw materials and product characteristics

[0054] Raw material properties (design value): flare gas H 2 S content is about 10000-35000m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com