Tripolycyanamide whole circulation production process and device

A melamine production process technology, applied in the new melamine full-cycle production process and equipment field, can solve the problems of many operators in the equipment area, increase the investment cost of tail gas treatment, increase the investment of melamine process tail gas treatment equipment, etc., and extend the operation cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

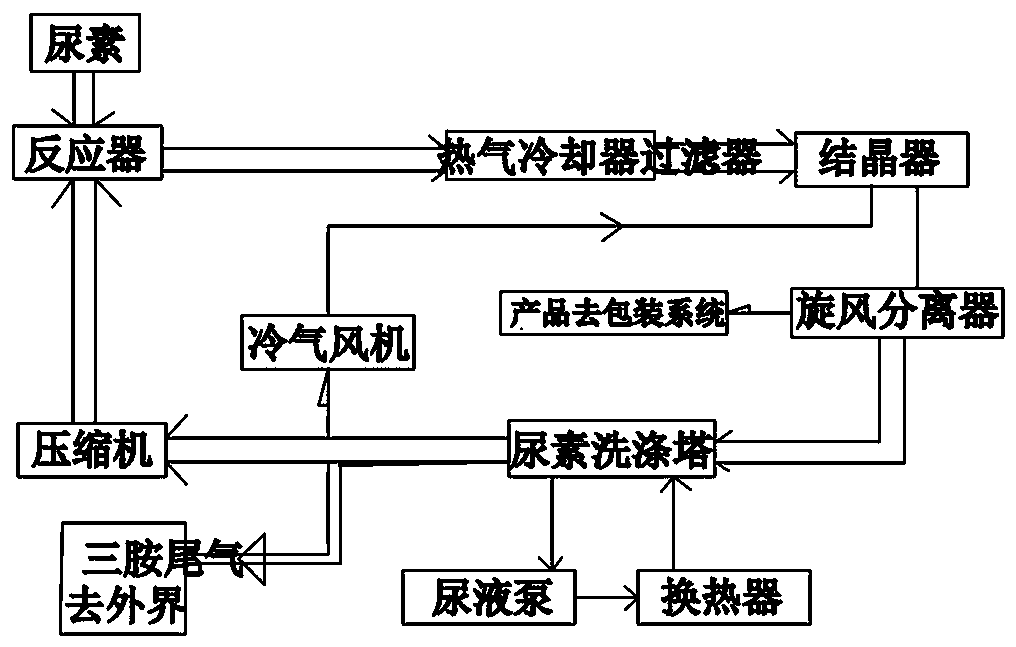

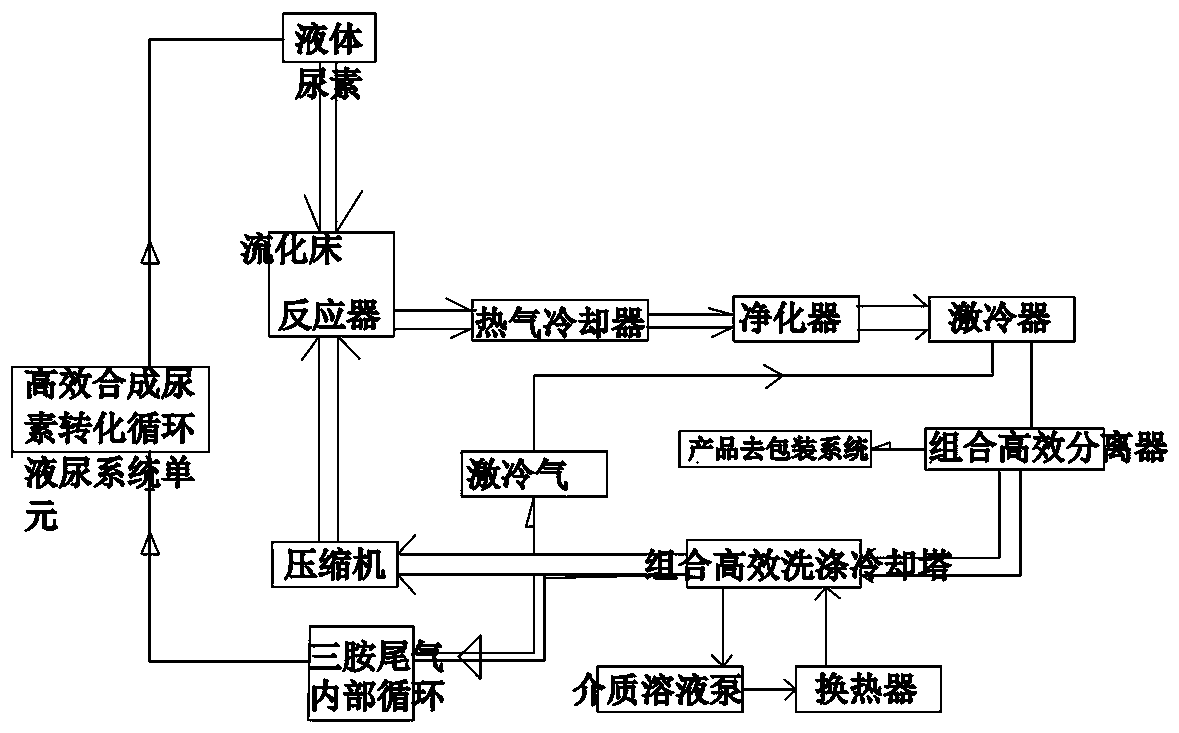

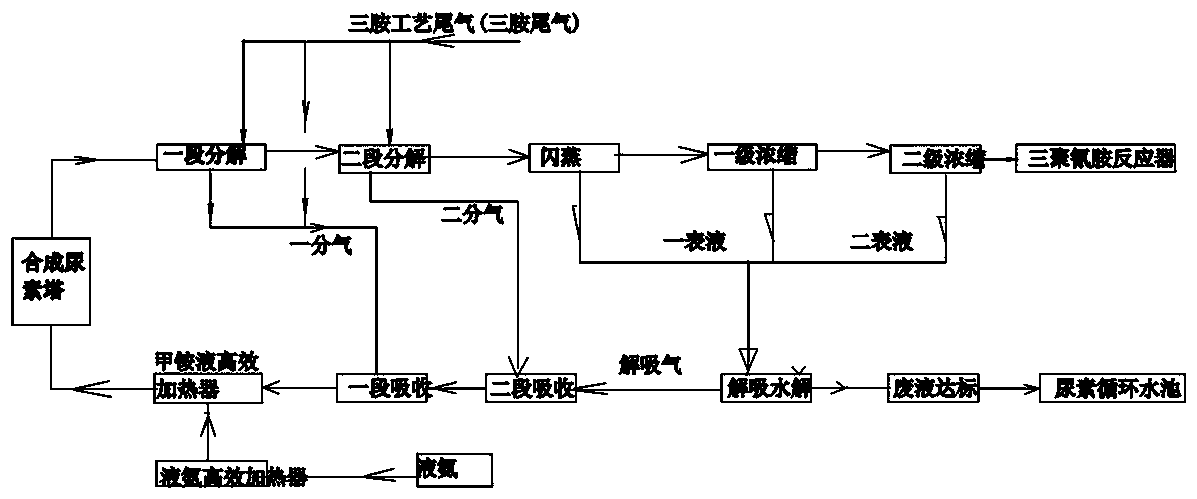

Method used

Image

Examples

Embodiment 1

[0061] (1) Enter the melamine fluidized bed reactor with liquid urea as the raw material, and react at 350-420°C and 0.1-2.6MPa pressure to generate melamine, ammonia and carbon dioxide gas mixture gas;

[0062] (2) The mixed material gas from the melamine reactor enters the hot air cooler at 350-420°C and 0.1-2.6MPa pressure, and is cooled to 320--340°C. After purification and separation, the process gas containing melamine enters the quenching process. The melamine is condensed into a solid phase in the gas phase, and the chilled process gas containing melamine enters the combined high-efficiency separator to separate the solid melamine and send it to the packaging system; the melamine process gas is converted into a circulating liquid urine system unit to synthesize liquid through high-efficiency synthetic urea The urea is recycled back to the melamine reactor to be used as a raw material for the melamine reaction.

[0063] (3) The gas containing ammonia and carbon dioxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com