Continuous enlarging cultivation device and method for mineral-bioleaching microorganisms

A technology for leaching microorganisms and expanding culture, which is applied in the field of continuous expanding culture devices for leaching microorganisms, can solve problems such as difficulty in chemical culture, and achieve the effects of convenient inoculation and expansion, compact structure and high culture efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

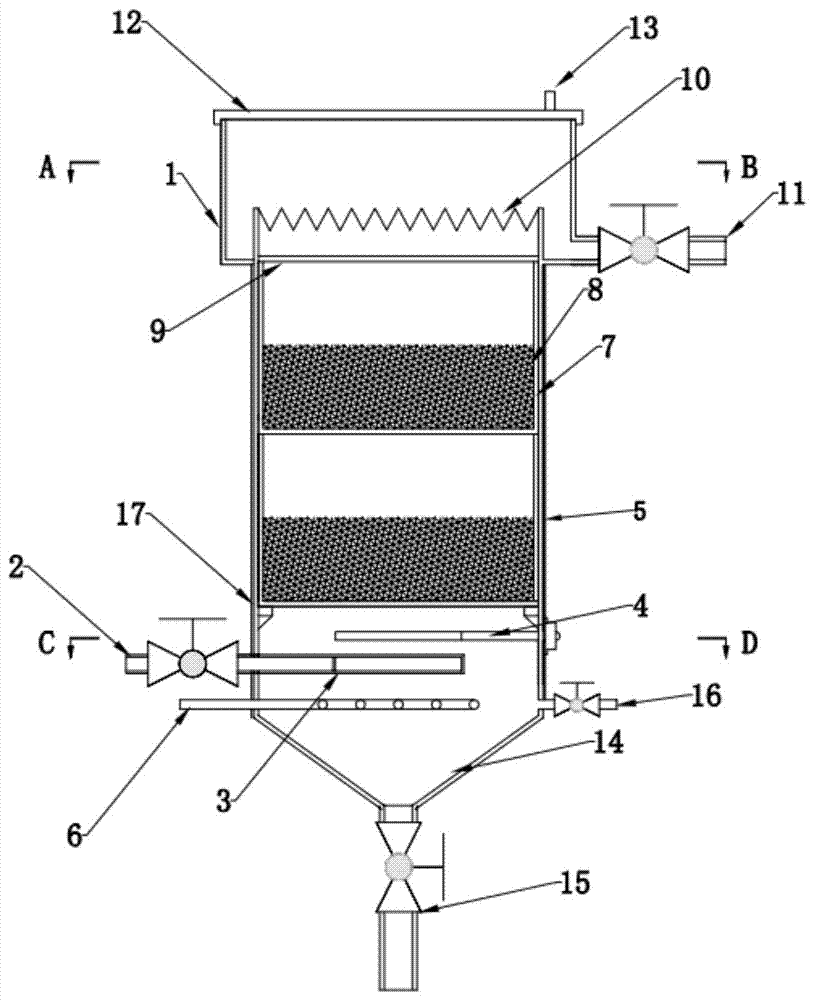

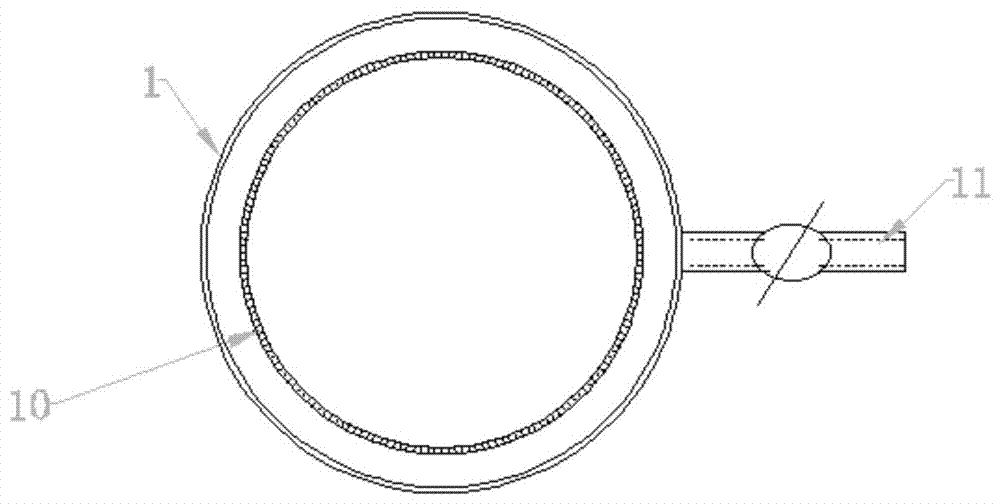

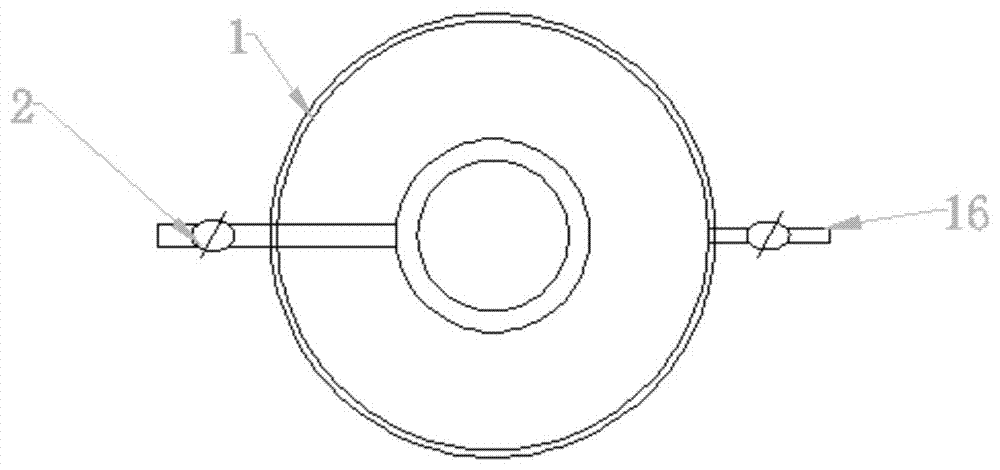

[0056] A kind of ore leaching microorganism continuous expansion culture device of the present invention, such as Figure 1-3 As shown, it includes cylinder 1, which is sequentially composed of an upper cylinder that can collect overflow discharge liquid, a middle cylinder that can continuously expand and cultivate microorganisms, and a lower cylinder 14 that can collect and discharge sediment. The top of the body is provided with a top cover 12, and the top cover 12 is provided with a top cover air outlet 13 and an observation window to ensure proper isolation of the microbial cultivation process from the outside world. The bottom side wall of the upper cylinder is provided with a feed liquid outlet 11; The top of the cylinder is provided with a sawtooth overflow weir device 10, which has the function of maintaining the liquid layer on the plate and making the liquid overflow evenly. The overflow weir device 10 is hollow embedded in the bottom of the upper cylinder; The botto...

Embodiment 2

[0061] A method for cultivating Thiobacillus ferrooxidans ( Acidithiobacillus ferrooxidans ATCC 23270, strain collection number: ATCC 23270, purchased from American Type Culture Collection), acidophilic heterotrophic bacteria ( Acidophilium acidophilum ATCC 27807, strain preservation number: ATCC 23270, purchased from American Type Microorganism Culture Collection), culture solution composition: (NH 4 ) 2 SO 4 , 2.5 g / L; MgSO 4 ·7H 2 O, 0.6g / L; K 2 HPO 4, 0.5 g / L; KCl, 0.1 g / L; Ca(NO 3 ) 2 , 0.01g / L; FeSO 4 ·7H 2 O, 50g / L.

[0062] The concrete operation of cultivating method comprises the following steps:

[0063] (1) Add the microbial culture solution through the feed port and the nutrient solution distribution plate, make it submerge the heating device and reach the bottom of the bottom packing assembly, adjust the pH to 1.5 by adjusting the acidity of the feeding medium, and set the culture temperature through the heating device 35°C, then uncover the top co...

Embodiment 3

[0070] A kind of cultivating and cultivating Thiobacillus ferrooxidans ( Acidithiobacillus ferrooxidans ATCC 23270, strain collection number: ATCC 23270, purchased from the American Type Microorganisms Collection), Leptohelicobacter ferrophilum ( Leptospirillum ferriphilum CS13, strain preservation number: M2015010, preservation place: China Center for Type Culture Collection), Sulfobacillus acidophilus ( Sulfobacillus acidophilus CS5, strain preservation number: M2015006, preservation location: China Center for Type Culture Collection). Composition of culture medium Composition of culture medium: (NH 4 ) 2 SO 4 , 2.5 g / L; MgSO 4 ·7H 2 O, 0.6g / L; K 2 HPO 4 , 0.5 g / L; KCl, 0.1 g / L; Ca(NO 3 ) 2 , 0.01g / L; FeSO 4 ·7H 2 O, 50g / L.

[0071] The concrete operation of cultivating method comprises the following steps:

[0072] (1) Add microbial culture solution through the feeding port and nutrient solution distribution plate, make it submerged in the heating device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com