Flash evaporation-sedimentation-fluidized bed separation combined purification method and device for coal gasification black water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

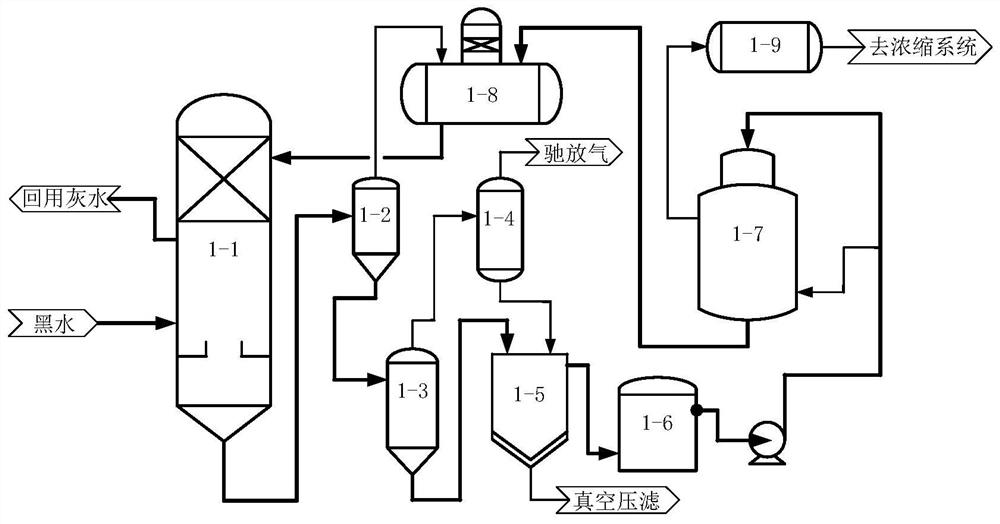

[0072] In the coal gasification black water treatment process of a 1.8 million tons / year coal gasification to methanol process, according to the method of the present invention, a flash evaporation-sedimentation-bubbling bed separation combined device is used to treat gasification black water containing fine particles The water is purified to achieve the purpose of efficient separation of particulate matter in the gasified black water.

[0073] 1. Material properties and related parameters

[0074] Coal gasification black water is a liquid-solid two-phase mixture, the water contains fine particles; the suspended solids content is 6000mg / L.

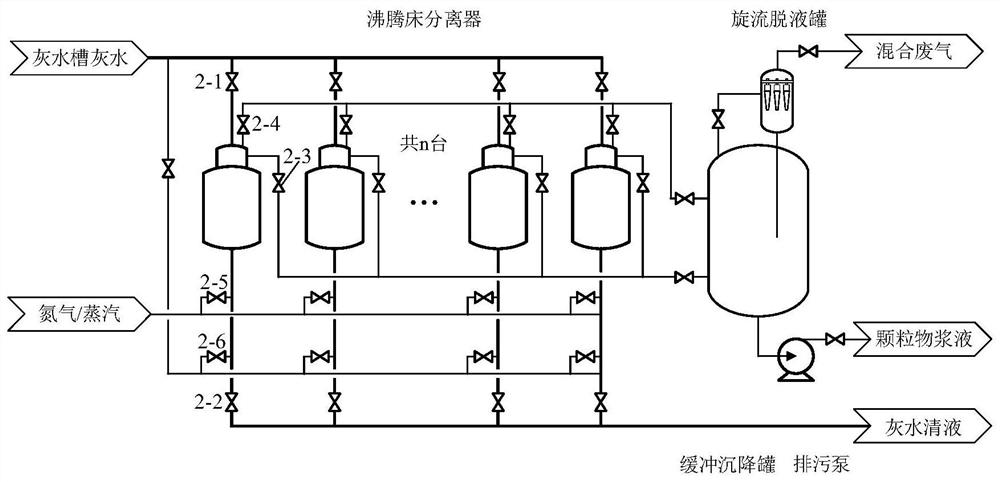

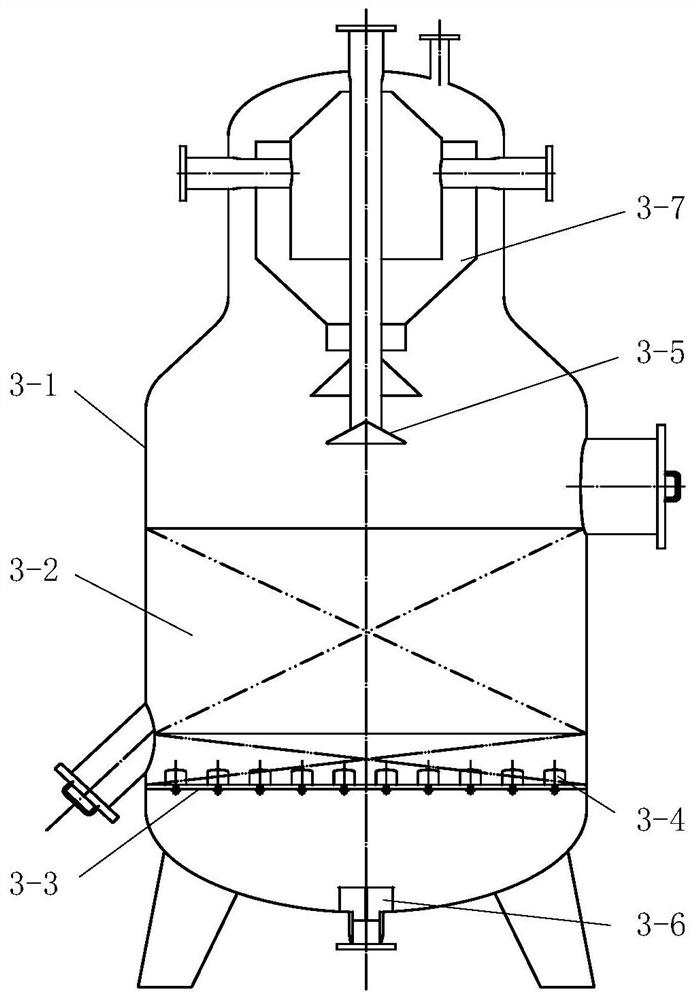

[0075] 2. Coal gasification black water purification device

[0076] The coal gasification black water purification device is a combined device of the original three-stage flash evaporation, sedimentation and supplementary ebullating bed separator. The diameter of the ebullating bed separator is 300mm, the height is 1500mm, and a cyclone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com