Method for deeply purifying iodine recycled from wet-process phosphoric acid and fluosilicic acid

A wet-process phosphoric acid, deep purification technology, applied in iodine/hydrogen iodide, iodine and other directions, can solve the problems of large iodine loss, complex production process, high cost, avoid waste of resources, solve complex production process, and widen economic benefits. and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

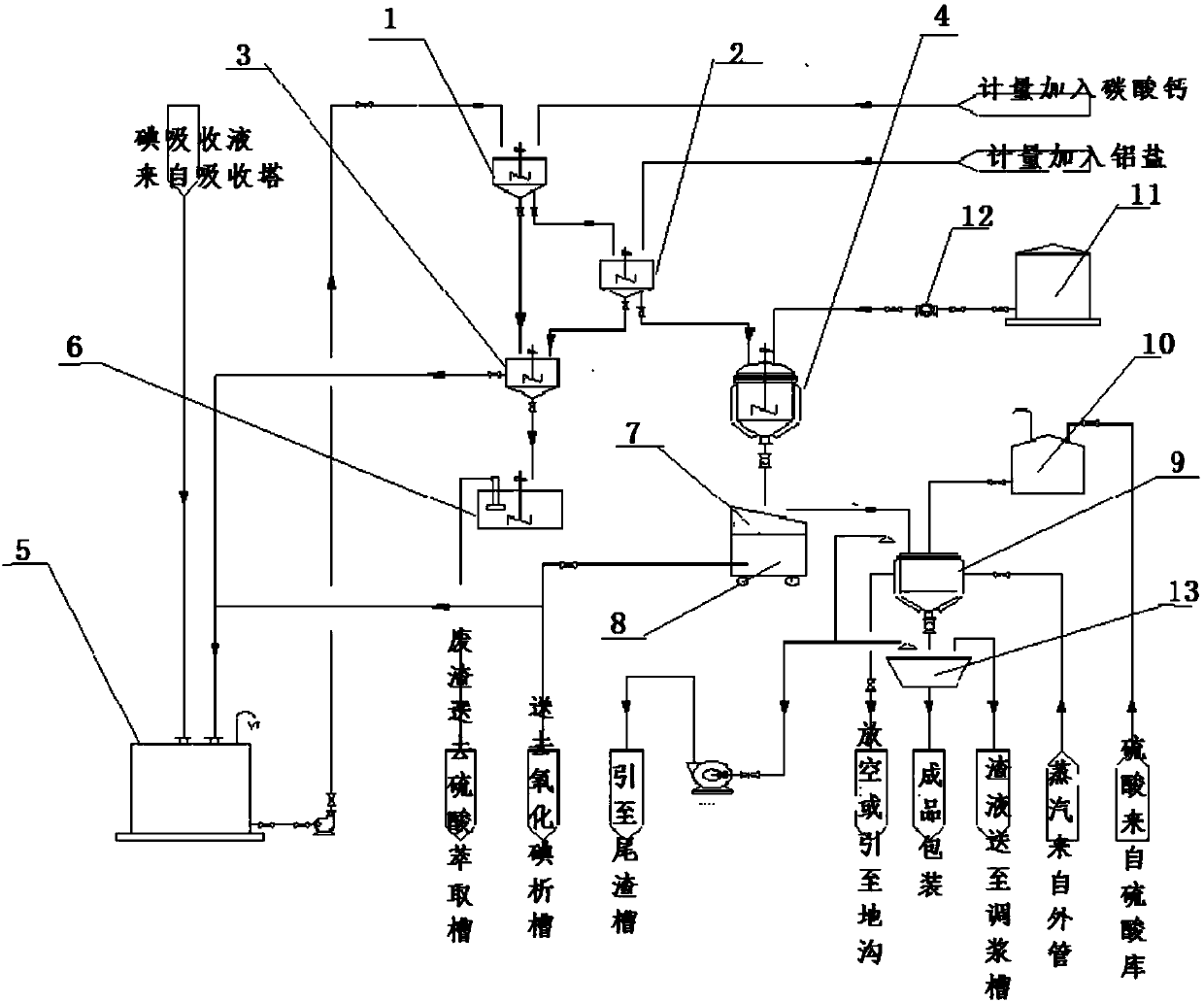

[0033] Purification and purification process of iodine recovery in wet-process phosphoric acid: a phosphoric acid workshop of Kailin Group uses about 60% of the associated iodine resources in phosphate rock into dilute phosphoric acid, which contains about 40mg / kg of iodine, expressed as H 2 o 2 As an oxidizing agent, iodide ions in wet-process phosphoric acid are oxidized into iodine molecules, and then the iodine molecules are blown off in the gas phase by air extraction, and then the iodine molecules in the gas phase are washed, absorbed and enriched by a reducing agent cycle. When the concentration of iodine ions in the absorption liquid After reaching 50g / L, iodine is purified and refined to obtain iodine products.

[0034] The recovery and purification process of iodine from wet-process phosphoric acid is as follows: figure 1 shown. Through the iodine absorption liquid circulation pump, the absorption liquid containing 50g / L iodine ion from the absorption liquid circul...

Embodiment 2

[0036] Purification and purification process of iodine recovery in wet-process phosphoric acid: a phosphoric acid workshop of Kailin Group uses about 60% of the associated iodine resources in phosphate rock into dilute phosphoric acid, which contains about 40mg / kg of iodine, expressed as H 2 o 2 As an oxidizing agent, iodide ions in wet-process phosphoric acid are oxidized into iodine molecules, and then the iodine molecules are blown off in the gas phase by air extraction, and then the iodine molecules in the gas phase are washed, absorbed and enriched by a reducing agent cycle. When the concentration of iodine ions in the absorption liquid After reaching 40g / L, carry out iodine purification and refinement and obtain iodine product.

[0037] The recovery and purification process of iodine from wet-process phosphoric acid is as follows: figure 1 shown. Through the iodine absorption liquid circulation pump, the absorption liquid containing 40g / L iodine ion from the absorption...

Embodiment 3

[0039] Purification and purification process of iodine recovery in wet-process phosphoric acid: a phosphoric acid workshop of Kailin Group uses about 60% of the associated iodine resources in phosphate rock into dilute phosphoric acid, which contains about 40mg / kg of iodine, expressed as H 2 o 2 As an oxidizing agent, iodide ions in wet-process phosphoric acid are oxidized into iodine molecules, and then the iodine molecules are blown off in the gas phase by air extraction, and then the iodine molecules in the gas phase are washed, absorbed and enriched by a reducing agent cycle. When the concentration of iodine ions in the absorption liquid After reaching 10g / L, carry out iodine purification and refinement to obtain iodine product.

[0040] The recovery and purification process of iodine from wet-process phosphoric acid is as follows: figure 1 shown. The absorption liquid containing 10g / L iodine ion from the absorption liquid circulation tank 5 enters the first-stage purifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com