Deep purification method and device for oilfield produced water

A technology for deep purification and production of water, applied in chemical instruments and methods, oil/oily substance/float removal devices, mining wastewater treatment, etc. Effect, simple equipment, simple effect of separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

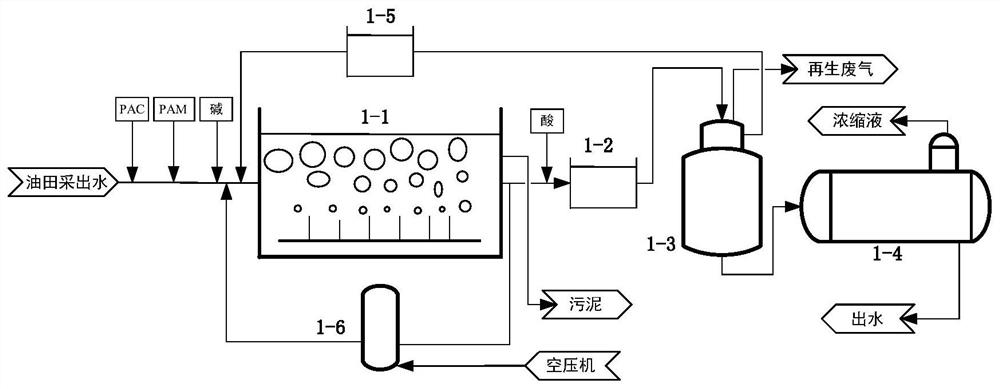

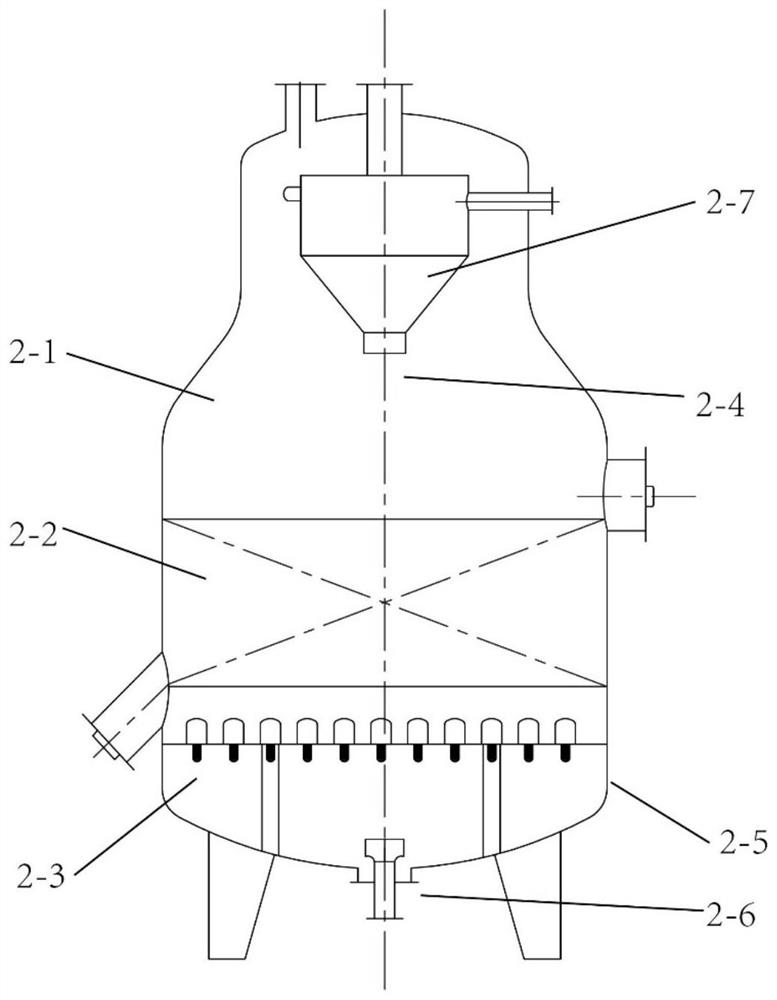

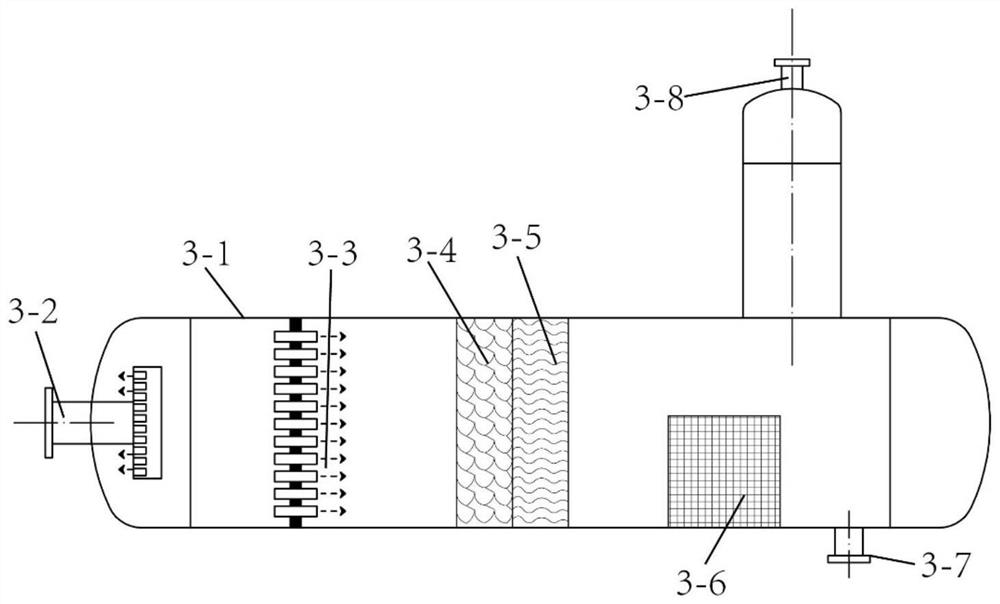

[0074] An oilfield produced water treatment device with a processing capacity of 20 cubic meters per hour was built in an oilfield in Karamay, Xinjiang. The process technology of the present invention was used for experiments, and the air flotation tank, fluidized bed separator and fiber coalescer were used for treatment, mainly to remove oilfield produced water. The suspended solids and oils in it were analyzed by detecting the indicators at the outlets of different devices to investigate the purification effect of the experiment.

[0075] 1. Material properties and related parameters of oilfield produced water

[0076] The oilfield produced water is a liquid-solid two-phase mixture. The water contains fine particles and a large amount of oil substances; the content of suspended solids is 1512mg / L, and the content of oil substances is 1826mg / L. The main substances are organic compounds of alkanes and aromatic hydrocarbons. substance.

[0077] 2. Oilfield produced water deep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com