Gear speed increasing assembly type high speed rotating casing pump unit

A rotary casing pump and assembled technology, which is applied in the direction of non-variable pumps, non-volume pumps, pumps, etc., can solve the problems of large bearing power consumption, large footprint, loose layout, etc., and achieve anti-cavitation performance Improvement, small size, and reduced deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

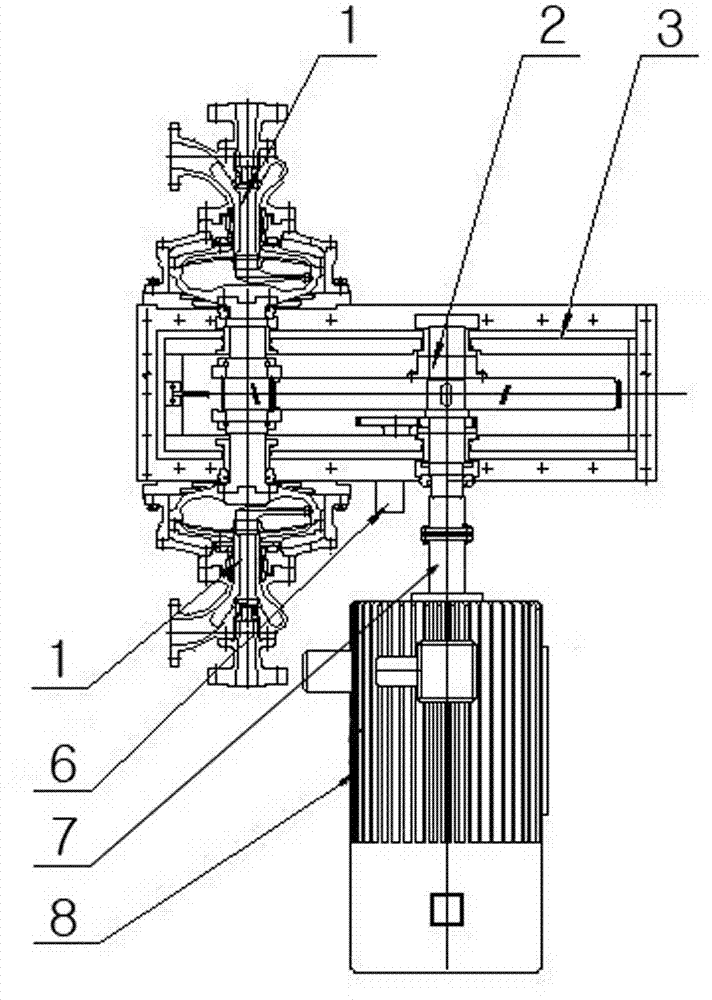

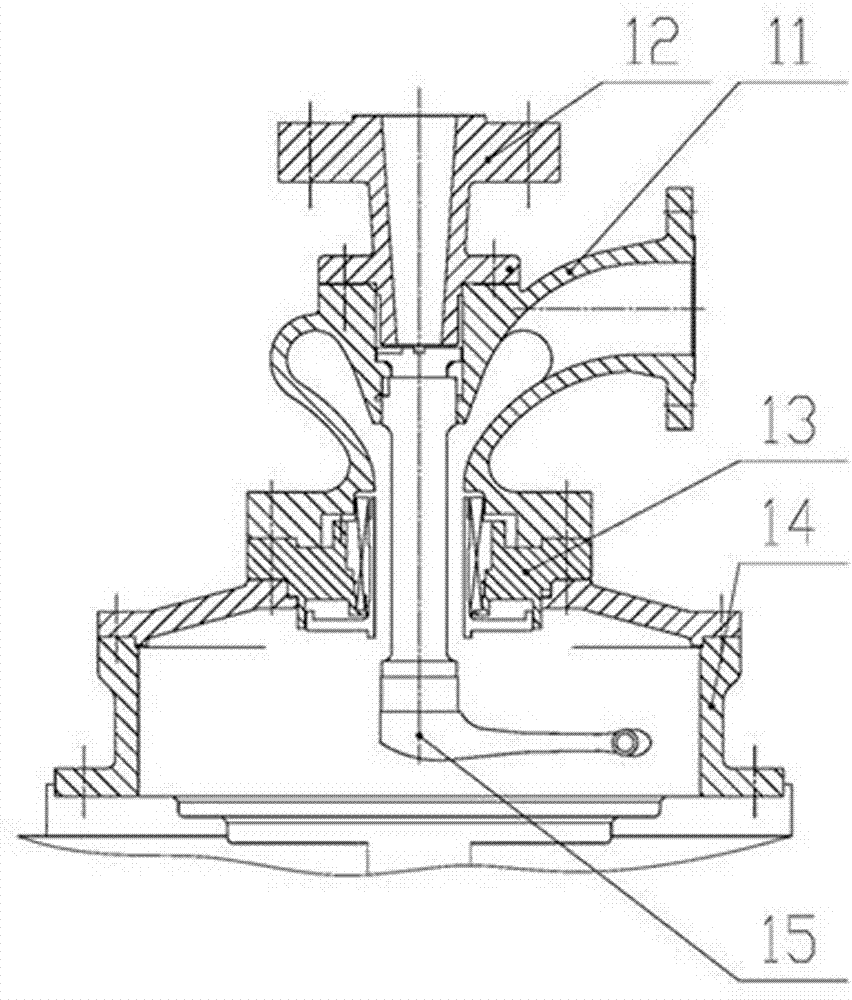

[0045] The hydrogenation feed pump of a petrochemical 1 million tons / year gasoline and diesel hydrocracking unit project is equipped with a front booster pump. Its performance parameters are flow: 67m3 / h, head: 1020m, inlet pressure 3.8MPa.G, outlet The pressure is 11.8MPa.G, the density is 800Kg / m3, the temperature is 50°C, and the NPSHa is ≤8m. The traditional rotary casing pump technology was used in engineering applications. Within 9 months of commissioning, 4 times the axial displacement vibration exceeded the standard, and one of the thrust bearings was seriously damaged. The main reason was that the axial force borne by the thrust bearing did not have enough safety margin. degree, did not meet the expected reliability.

[0046]

[0047] Comparison of the advantages of adopting this technical solution:

[0048] 1) The structure is symmetrically arranged, and the axial force is self-balanced. Compared with the existing rotary casing pump technology, the axial force ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com