Inferior crude oil lightweighting method

A technology of low-quality raw oil and lightening, which is applied in the fields of hydrocarbon oil cracking, petroleum industry, processing of hydrocarbon oil, etc., can solve the problem that low-quality raw oil cannot be efficiently converted into light distillate oil, etc., so as to avoid catalyst deactivation and improve yield. Efficient and efficient processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] The method of the present invention has no special limitation on the preparation method of the hydrogenation catalyst, which can be prepared by conventional methods such as impregnation method in this field, and the present invention will not repeat them here.

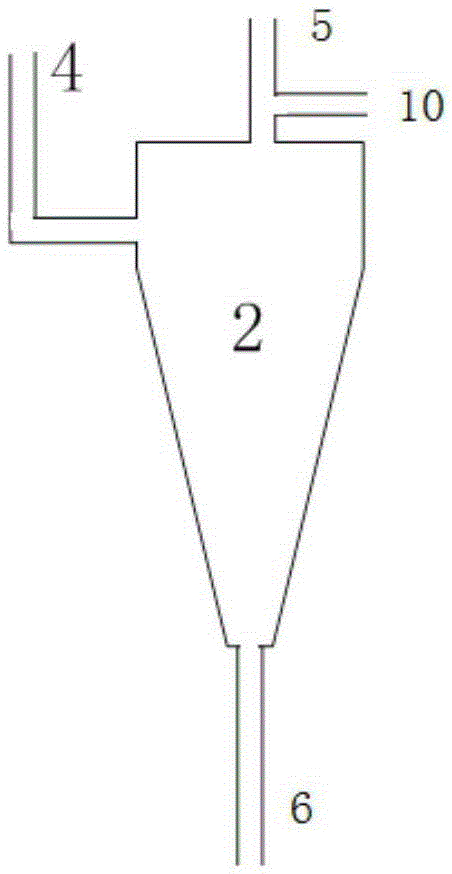

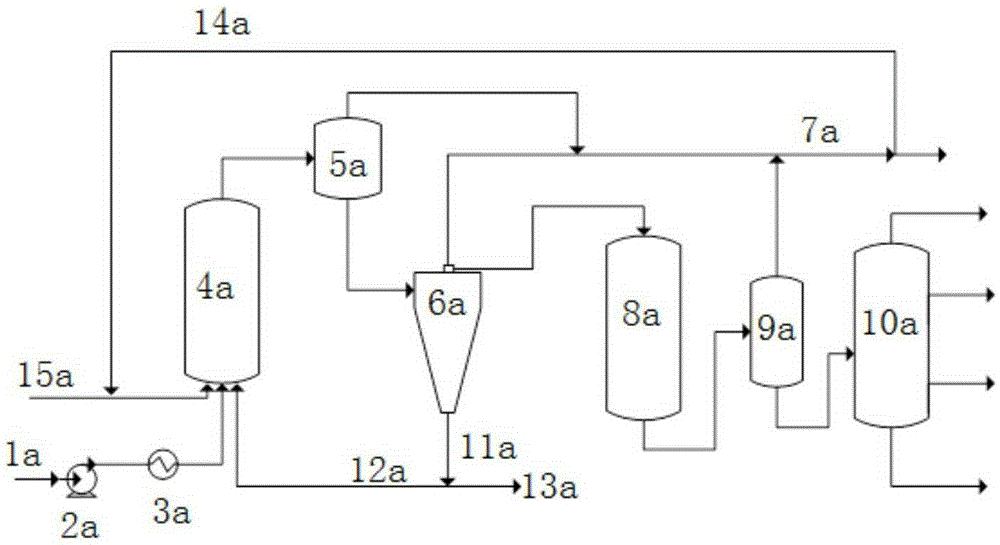

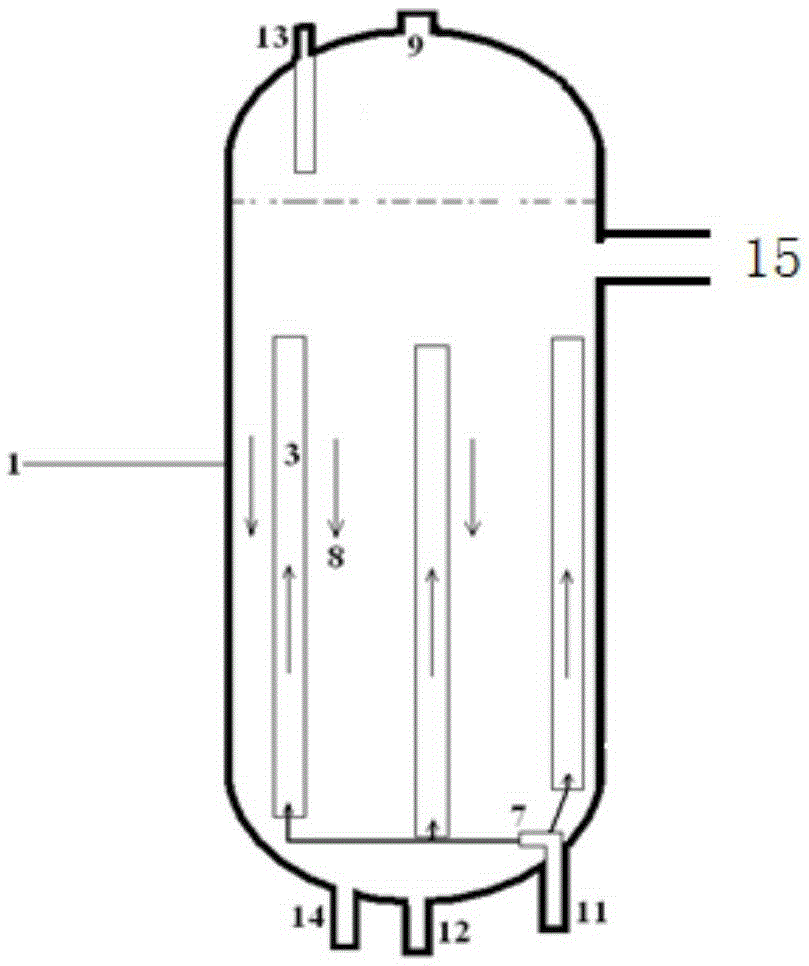

[0080]After the hydrogenation catalyst and the inferior raw material oil are evenly mixed, they enter the slurry bed reactor together for hydrocracking reaction. After the reaction system is balanced, the high-density tail oil flowing out of the bottom flow pipe of the hydrocyclone is thrown out of the reaction system. Remove the partially deactivated hydrogenation catalyst in the hydrocracking reaction system of the slurry bed reactor at a certain rate, and at the same time replenish fresh hydrogenation catalyst to the raw material at the same rate, so that the catalyst content in the slurry bed reactor remain within the foregoing scope of the invention.

[0081] The inferior raw material oil of the present inv...

Embodiment 1-3

[0111] The hydrogenation catalysts used in Examples 1-3 are the same, and are Mo-based supported catalysts. The specific composition is: in terms of active metals, the Mo (average particle diameter is 45nm) content is 10% by weight, and the rest is carrier activated carbon. The average particle diameter of the hydrogen catalyst was 100 μm.

[0112] The consumption amount of the hydrogenation catalyst is shown in Table 2 in terms of the metal content in the hydrogenation catalyst per g of the inferior raw material oil.

[0113] The low-quality feedstock oils used in Examples 1-3 are the same, deoiled bitumen A and Zhenhai catalytic cracking oil slurry in a weight ratio of 7:3.

[0114] The fixed-bed hydroprocessing unit used in the experiments in Examples 1-3 is a single-reactor small-scale fixed-bed hydroprocessing unit, which is filled with protection catalyst, demetallization catalyst, desulfurization catalyst and denitrogenation catalyst in sequence. The grade of the hydrop...

Embodiment 4-5

[0134] Embodiment 4-5 adopts the method identical with embodiment 2 to carry out hydrocracking reaction, difference is, the reaction temperature in described fixed-bed hydroprocessing unit is different from that in embodiment 2, specifically as in table 5 shown.

[0135] table 5

[0136] Example 4 Example 5 Reaction conditions Pressure / MPa 14.0 14.0 temperature / ℃ 390 410 Liquid hourly volumetric space velocity / h -1

[0137] From the results of Example 2, Example 4 and Example 5, it can be seen that with the increase of reaction temperature, the yield of hydrogenated tail oil decreases, while the properties of hydrogenated tail oil become better, and it can be used as high-quality heavy oil catalytic cracking raw material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com