Sterilization method capable of preventing reverse osmosis membrane from being polluted and plugged by microbe

A technology of reverse osmosis membrane and microorganisms, which is applied in the fields of semipermeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc. It can solve problems affecting the performance of reverse osmosis devices, mechanical damage of membrane elements, and decline in water production. , to achieve the effects of controlling breeding and over-breeding, eliminating pressure rise factors, and saving cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

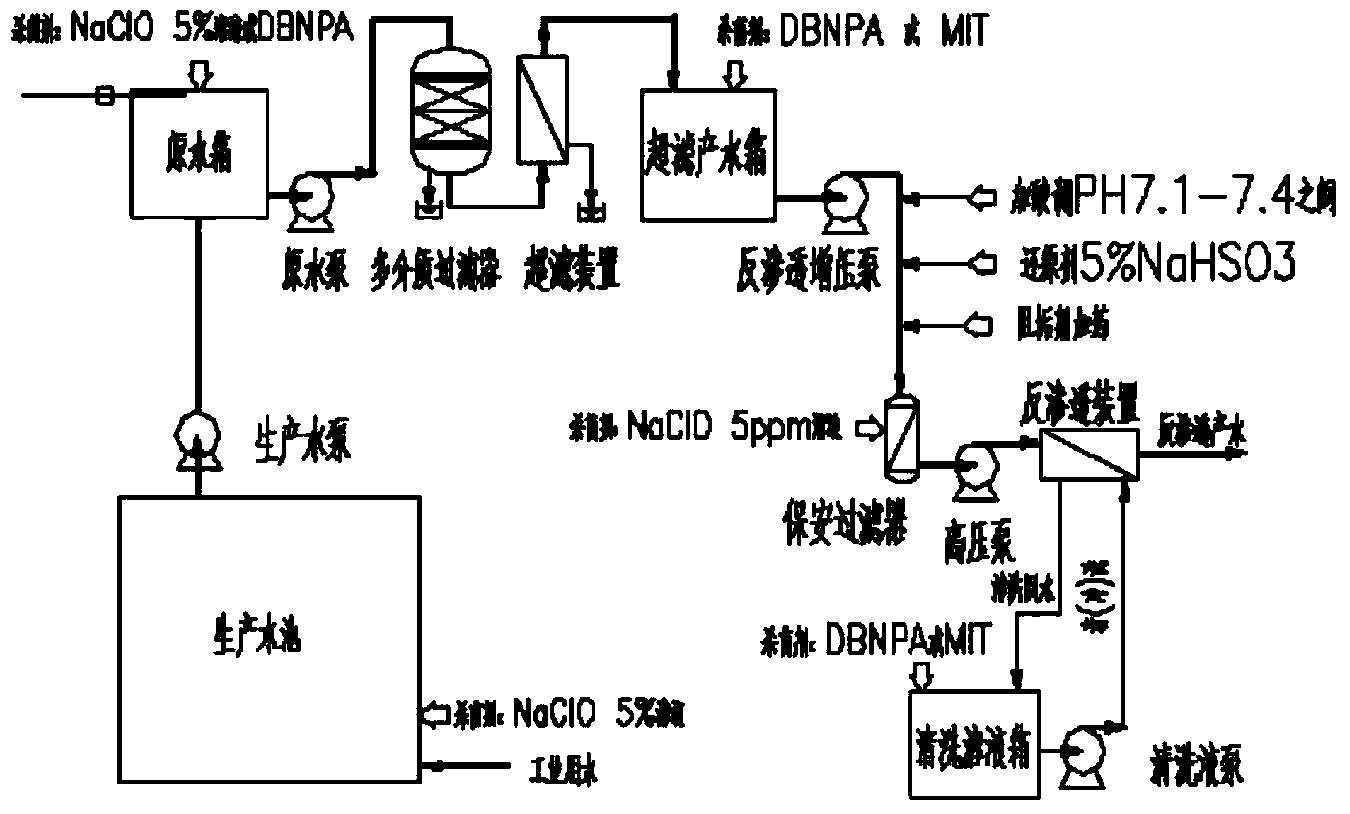

Image

Examples

Embodiment Construction

[0039] Method of the present invention specifically comprises the steps:

[0040] 1. Selection of fungicides

[0041] 1) Oxidizing fungicide: usually a strong oxidizing agent, which has a strong killing effect on microorganisms in water. It can denature proteins, and the shell of bacteria is usually a layer of protein, which will lead to the death of bacteria after protein denaturation. Commonly used oxidizing biocides are compounds with oxidizing properties such as chlorine-containing compounds, peroxides, and bromine-containing compounds. These compounds generally have the advantages of fast bactericidal and algae killing speed, high broad-spectrum bactericidal effect, low treatment cost, relatively small impact on environmental pollution, and microorganisms are not easy to produce drug resistance. The disadvantage is that it is greatly affected by organic matter and reducing substances in the water, the action time of the agent is short, and it is also greatly affected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com