Self-cleaning horizontal type dirt remover

A horizontal type decontamination device, self-cleaning technology, applied in fixed filter element filters, chemical instruments and methods, filtration and separation, etc. Simple structure, high cleaning efficiency, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

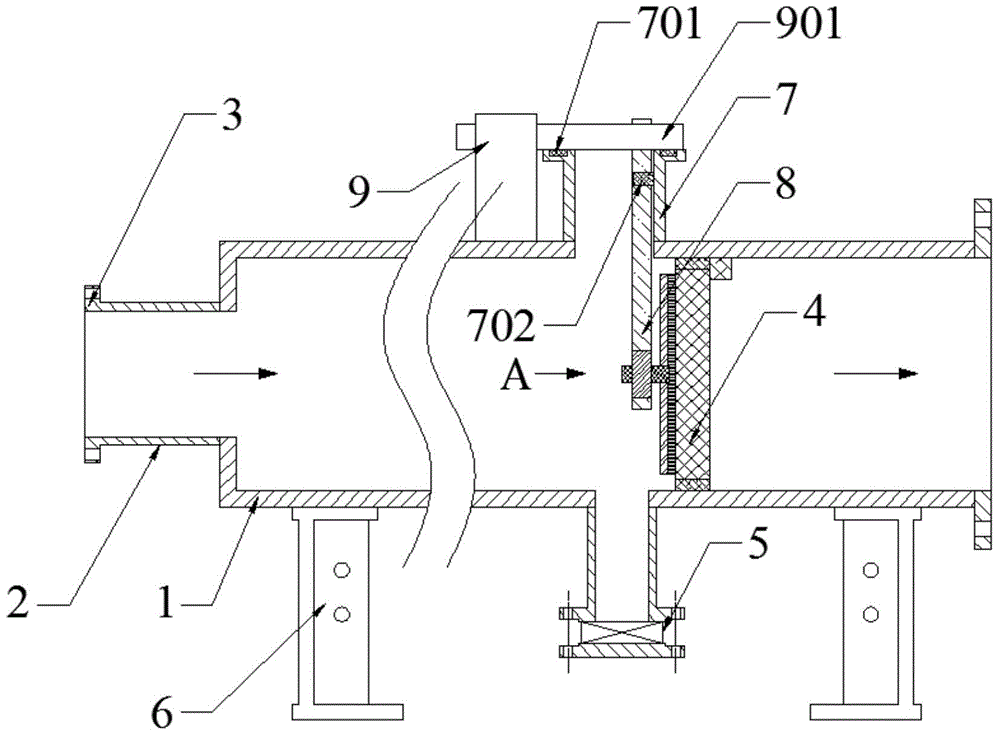

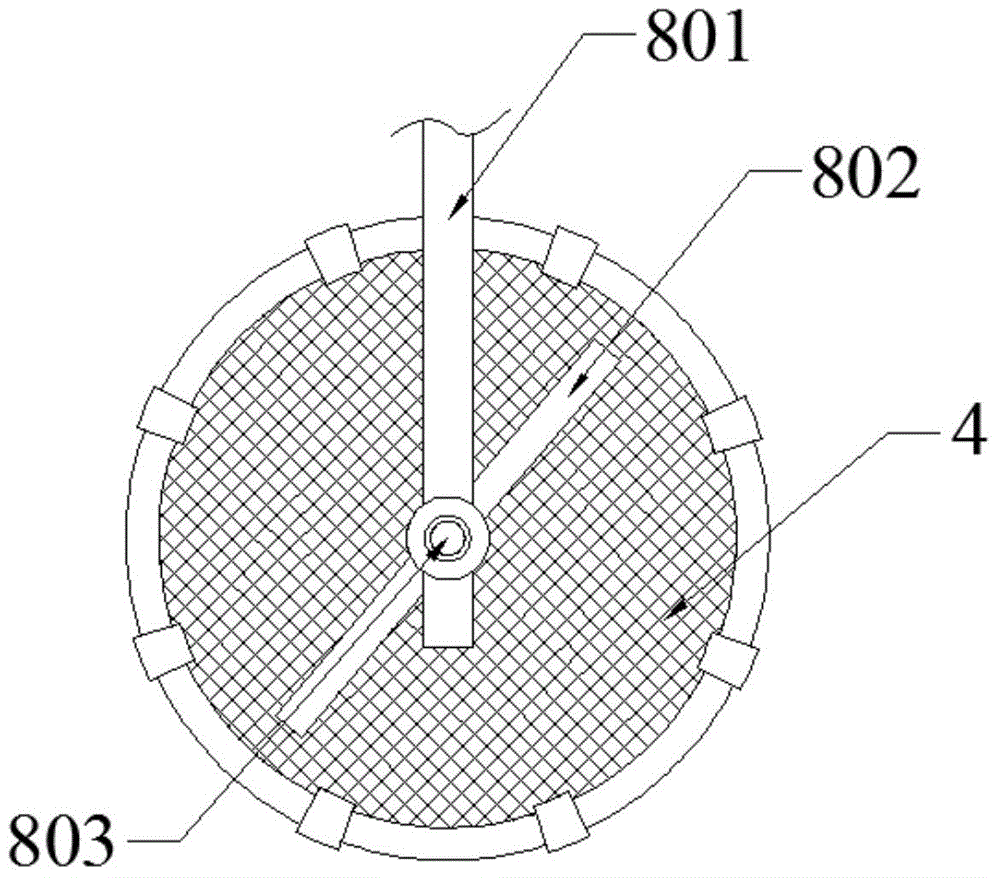

[0016] Such as figure 1 and figure 2 As shown, a self-cleaning horizontal decontamination device includes a main body 1, a filter screen 4 arranged in the main body 1, a sewage discharge assembly 6 communicated with the main body 1, a cleaning assembly 8, and a movable assembly 9 that drives the cleaning assembly 8 to move and control components.

[0017] The body 1 is provided with an inlet port and an outlet port. The inlet end is provided with a neck tube 2 whose radius is smaller than that of the body 1 . Flanges 3 are provided at the outlet ends of the neck pipe 2 and the body 1, so as to seal the body 1 into the pipeline. The filter screen 4 is arranged in the body 1 and is detachably connected with the body 1 . The aperture of the filter screen 4 is small, and is mainly suitable for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com