Method for preparing porous separation membrane

A porous separation membrane and membrane-forming technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve problems such as uselessness and unusable separation of membrane materials, and achieve simple production methods, low production costs, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

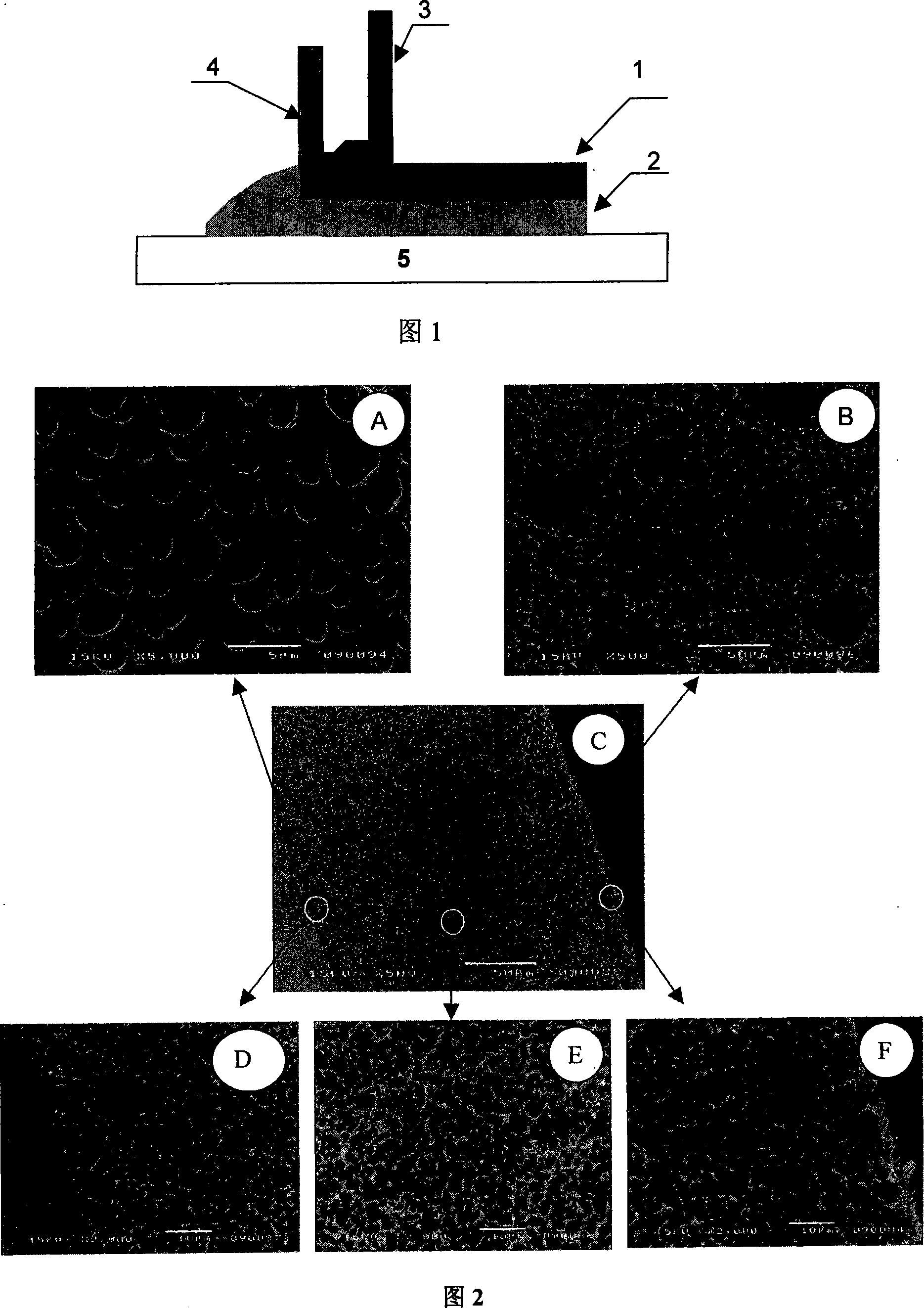

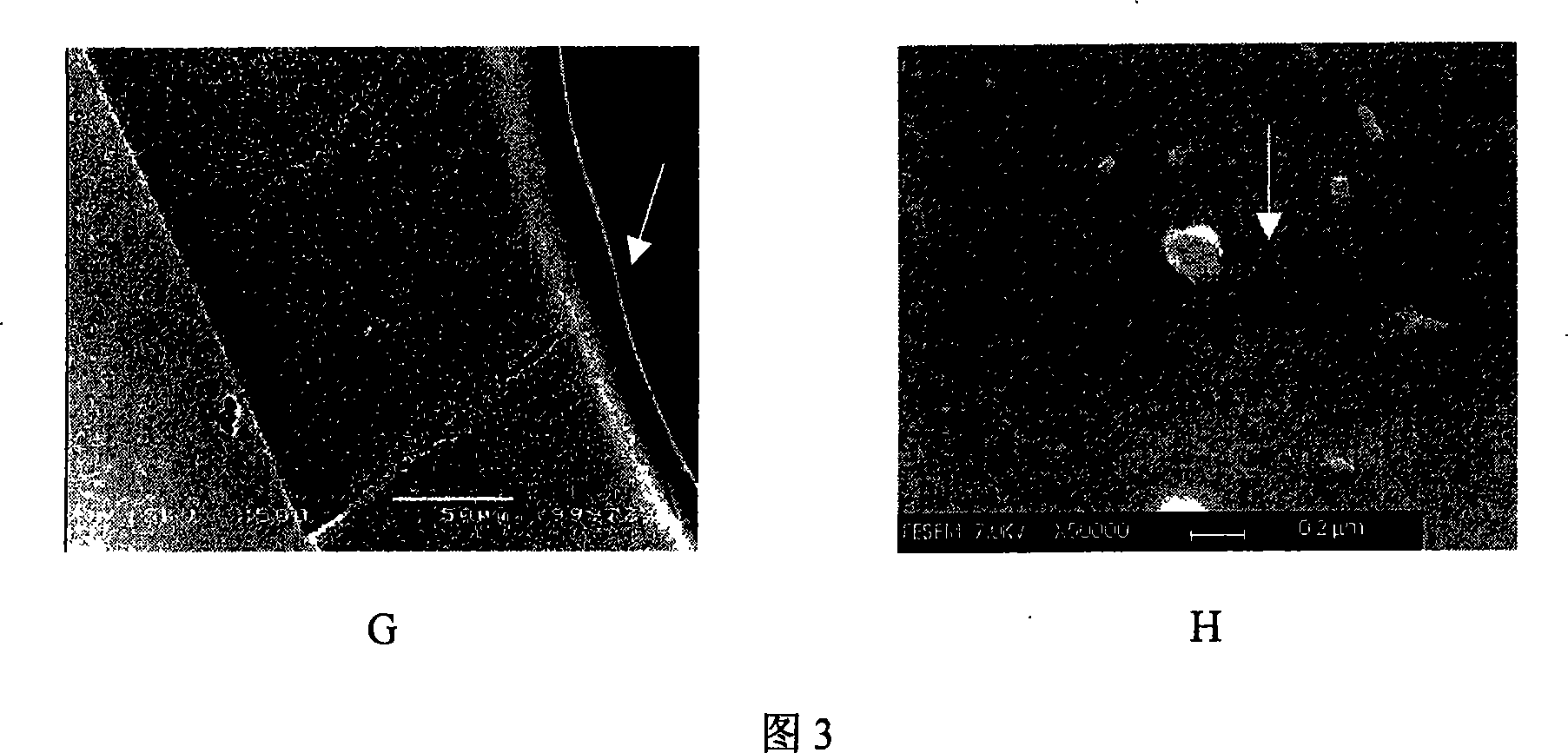

[0028] 15.0 grams of polysulfone and 15.0 grams of polyvinylpyrrolidone ((PVP K90) were dissolved in 70 grams of nitrogen-methylpyrrolidone to prepare a support layer solution. The solution had a viscosity of 1100 centipoise at 25°C. Polyether acyl Imine (PEI) 20 grams and 80 grams of nitrogen-methylpyrrolidone are mixed with composite layer solution.Utilize double-layer scraper that two kinds of solutions are spread on the smooth and dry glass plate simultaneously, and two-layer thickness is respectively 100 and 300 microns; Place it in the air (20.0±2°C, relative humidity 55%) for about 2 seconds and then immerse in water for phase separation and solidification. When the composite layer and the support layer are completely cured, the polyimide film and the polysulfone film are completely separated. Measure poly The pure water permeability of the sulfone membrane is 190L.m -2 .hr -1 .bar -1 . The polysulfone membrane was soaked in 4000ppm sodium hypochlorite aqueous soluti...

Embodiment 2

[0033] Dissolve 17.0 grams of polysulfone and 15.0 grams of polyvinylpyrrolidone ((PVP K90) in 70 grams of nitrogen-methylpyrrolidone to prepare a support layer solution. The solution has a viscosity of 1500 centipoise at 25°C. Polyimide (PEI ) 15 grams and 85 grams of nitrogen-methylpyrrolidone are prepared into a composite layer solution. Utilize a double-layer scraper to spread the two solutions onto a smooth and dry glass plate simultaneously, and the thickness of the two layers is respectively 100 and 300 microns; in air (20.0 ± 2 ℃, relative humidity 45%) placed in the water for about 2 seconds and then immersed in water for phase separation and solidification. When the composite layer and the support layer are completely cured, the polyimide membrane and the polysulfone membrane are completely separated. The polysulfone membrane is slightly exposed to the air Immerse in 4000ppm sodium hypochlorite aqueous solution after drying in the medium. After 48 hours, take out the ...

Embodiment 3

[0035] 17.0 grams of polyethersulfone and 30.6 grams of diethylene glycol ((DegOH) were dissolved in 52.4 grams of nitrogen-methylpyrrolidone to prepare a support layer solution. The solution had a viscosity of 53 centipoise at 25°C. Polyethersulfone (PES ) 17 grams and 83 grams of nitrogen-methylpyrrolidone to prepare a composite layer solution. Utilize a 200 micron scraper to spread the support layer solution onto a smooth and dry glass plate, and place it in the air (20.0 ± 2 ° C, relative humidity 95%) After 15 seconds, the surface of the support layer solution was milky white, and then the composite layer solution was spread on the support layer solution with a 250 micron scraper; quickly immersed in water for phase separation and solidification. When the composite layer and the support layer were cured, the composite polyether was found The sulfone membrane and the underlying polyethersulfone membrane are completely separated. After immersing the underlying polyethersulfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com