Garbage leachate treatment process

A technology for landfill leachate and treatment process, applied in the field of waste treatment, can solve the problems of high treatment cost, poor applicability, frequent cleaning, etc., and achieve the effects of reducing cleaning frequency, lightening burden, and reducing investment costs and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

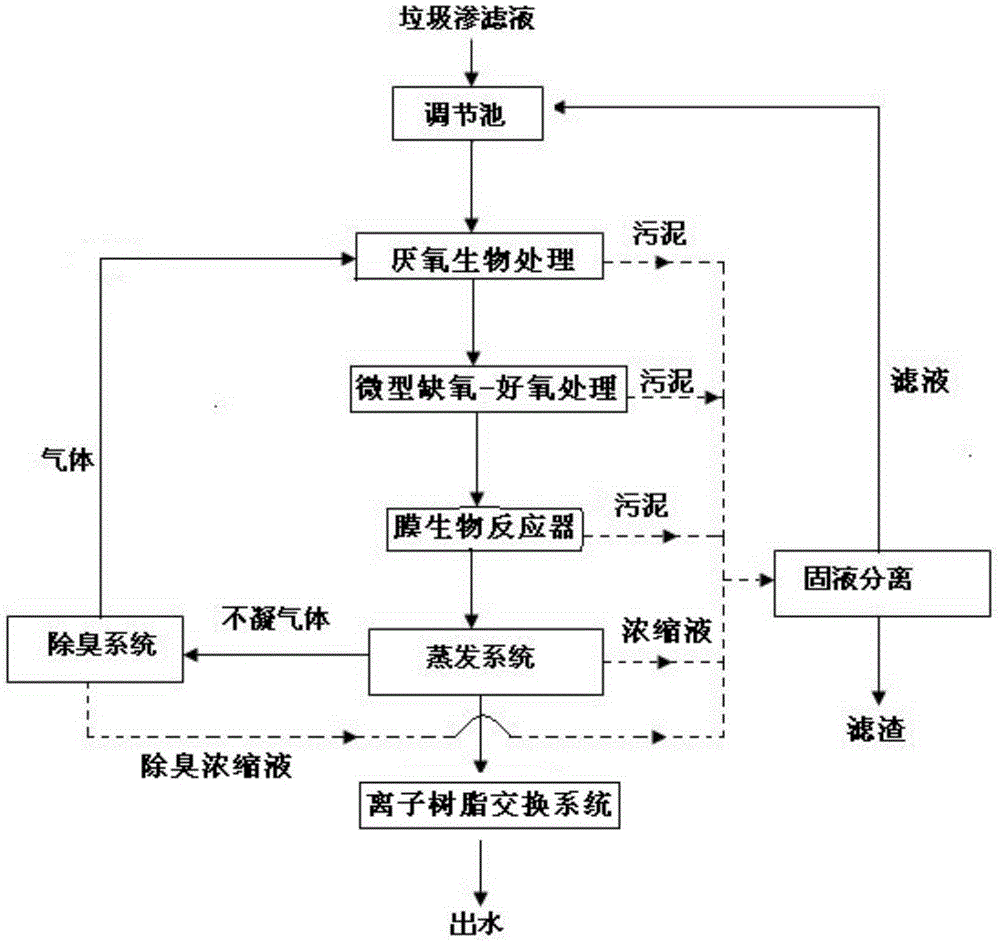

[0037] Such as figure 1 A treatment process for landfill leachate is shown, including transporting landfill leachate into a regulating tank to stabilize the water quality and quantity of the effluent from the regulating pond;

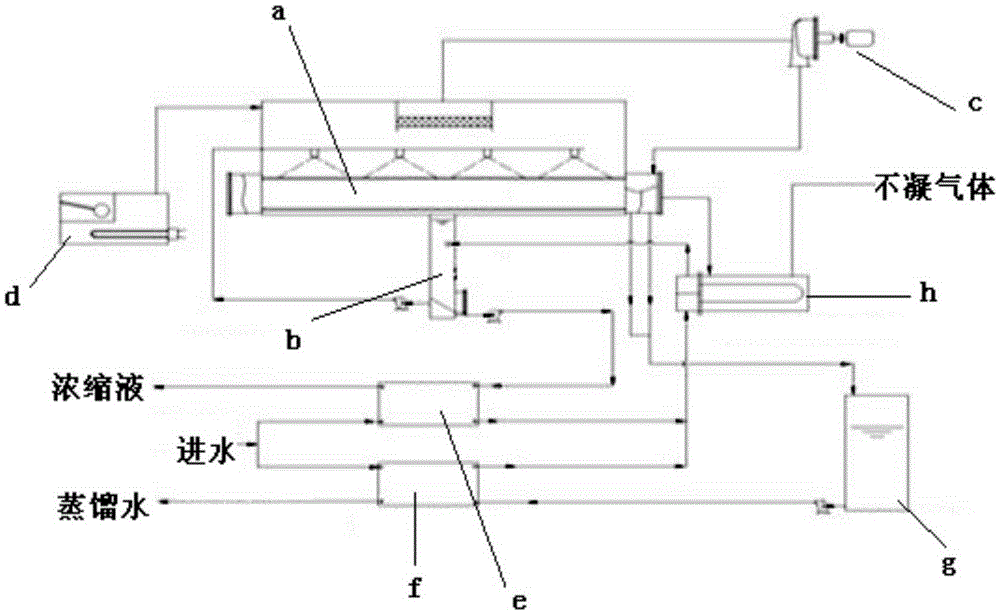

[0038] The landfill leachate flowing out of the regulating tank needs to be pretreated before entering the evaporation system for evaporation, such as figure 2 Shown is the process flow chart of pretreatment, and its process flow includes,

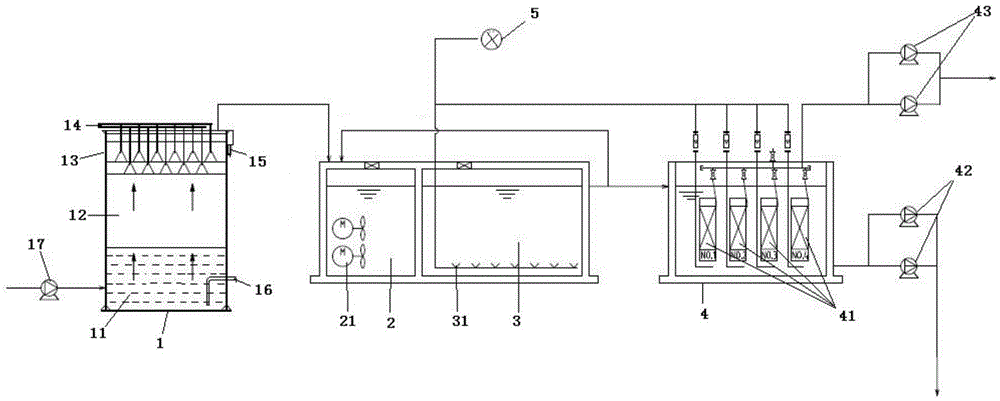

[0039] (1) The leachate from the regulating tank enters the anaerobic biological treatment unit to reduce the COD content of the anaerobic biological treatment effluent and reduce the load of subsequent operations; the anaerobic biological treatment unit is an upflow anaerobic sludge bed reactor (UASB) 1. It has the characteristics of simple operation, less residual sludge and lower cost. The UASB pump 17 transports the effluent of the regulating tank to the water distribution system at the bottom of the UASB rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com