Sugar-manufacturing single-layer precipitator control system

A control system and settler technology, applied in the field of sugar-making single-layer settler control system, can solve the problems of lack of process control means, unable to achieve stepless adjustment of liquid level, etc., and achieve good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

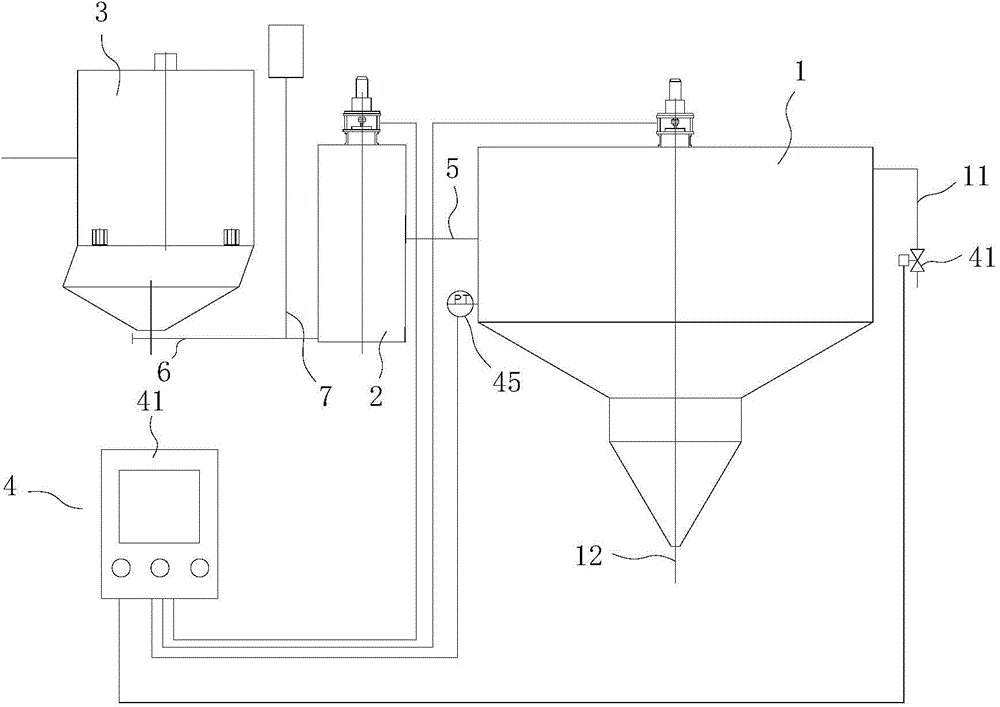

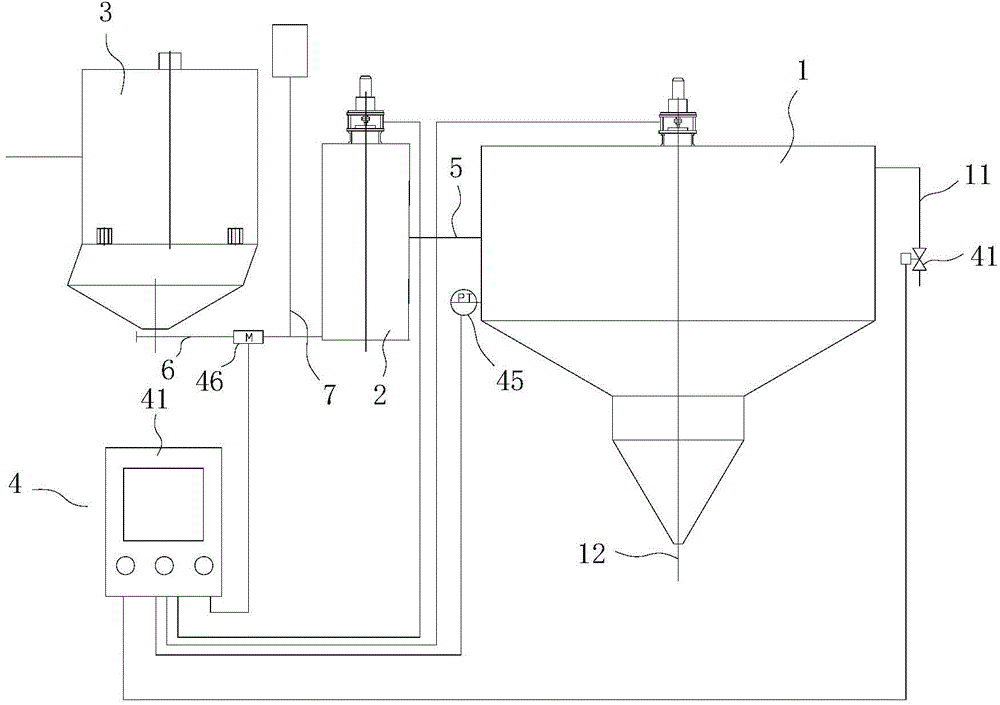

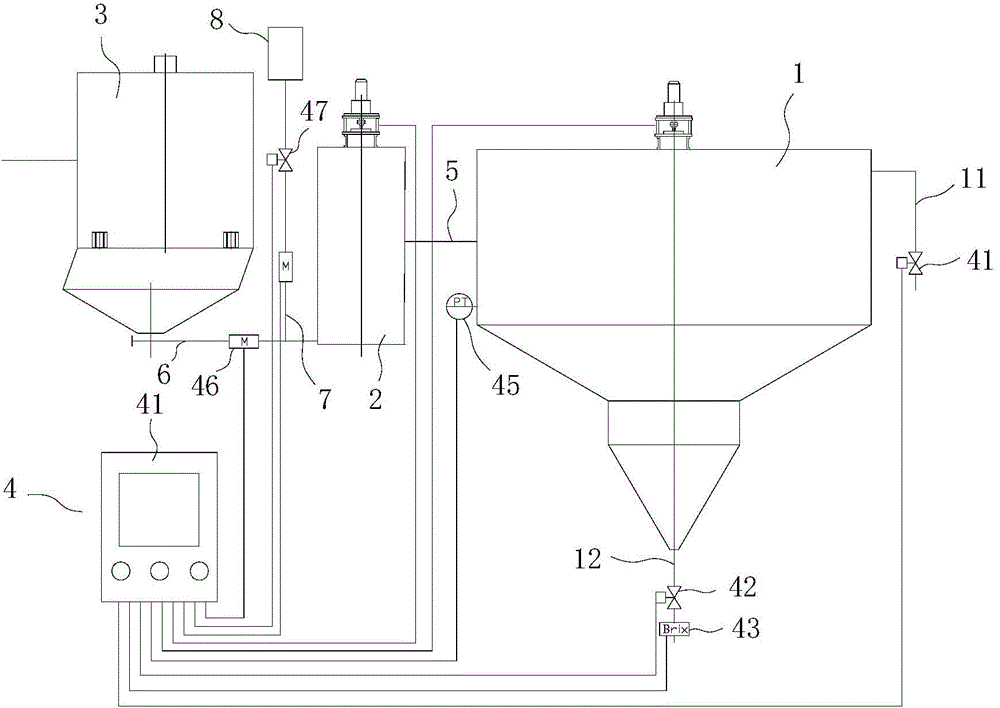

[0026] Please refer to figure 1 , is the first embodiment of the present invention. This embodiment adopts the technical means of setting a controller 41, a clear juice regulating valve 44 and a liquid level sensor 45 in the control system 4, so that the liquid level information detected by the liquid level sensor 45 is transmitted to the control system. 41, the controller 41 adjusts the opening degree of the clear juice regulating valve 44 to control the liquid level by comparing the detected value with the set value, so as to achieve the purpose of roughly controlling the hydraulic retention time by setting and maintaining the liquid level, and realize the neutralization reaction to sulfur fumigation Stepless adjustment of time.

[0027] The structure of this embodiment consists of a settler 1 , a flocculation reactor 2 , an air diffuser 3 , a control system 4 , and a controller 41 in the control system 4 , a clear juice regulating valve 44 , and a liquid level sensor 45 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com