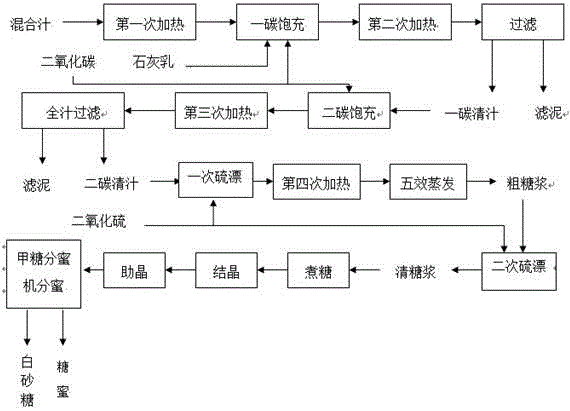

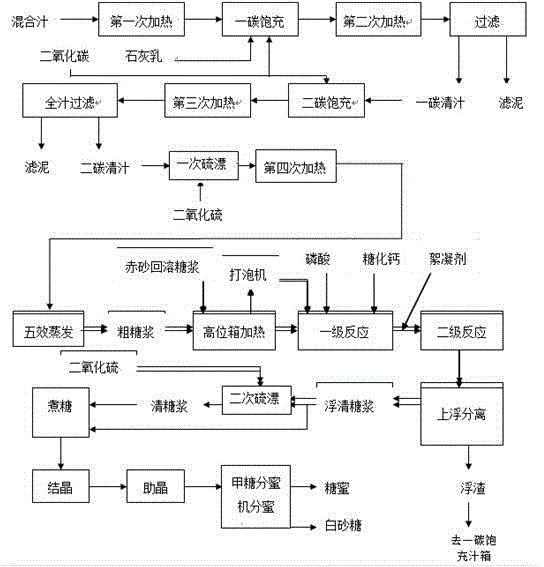

Sugar-juice syrup floating clarification process used in carbonation method

A technology of carbonation and syrup, which is applied in the purification of sugar juice, sucrose production, sugar production, etc. It can solve the problems of poor impurity removal and other problems, and achieve the effects of reducing honey making factors, improving product quality, and reducing material viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First prepare coarse syrup 1, then pump the coarse syrup to the syrup high level tank and mix it with red sand back-dissolving syrup. At the same time, check and analyze the contents of various indicators of the mixed syrup. The result is: Brix 61.36°Bx, sulfur content Amount of 315mg / kg, depending on the purity of 88.88%, pH 7.31, and directly heat the crude syrup to 75-85°C with waste steam in the high-level syrup tank, and foam at a ratio of 8%, while adding 300ppm of phosphoric acid and 8 ppm of calcium saccharification. First reaction, then add flocculant 10ppm to carry out secondary reaction, after fully mixing, sample and observe before the secondary reactor flows into the floater, most of the scum floats up quickly, clear, and there are a few small particles, which are floated and separated by the floater Inspection and analysis of various indicators of Fuqing syrup, the results are: Brix 61.00°Bx, sulfur content 238mg / kg, apparent purity 88.92%, pH value 6.73. ...

Embodiment 2

[0034] First prepare coarse syrup 1, then pump the coarse syrup to the syrup high level tank and mix it with the red sand back-dissolving syrup. At the same time, check and analyze the content of various indicators of the mixed syrup. The result is: Brix 65.27°Bx, sulfur content Amount of 383mg / kg, depending on the purity of 88.26%, pH value 7.02, and directly heat the crude syrup to 75-85°C with waste steam in the high-level syrup tank, and foam at a ratio of 8%, while adding 300ppm of phosphoric acid and 6 ppm of calcium saccharification. First reaction, then add flocculant 6ppm for the second reaction, after fully mixing, take samples before the secondary reactor flows into the buoyant, the floating speed is fast, it is foggy at first, it starts to be clear after 15 minutes, and it is all clear after 25 minutes, and the floating is relatively fast. In the late stage, it is relatively dense. After being floated and separated by the floater, various indicators of the floating ...

Embodiment 3

[0038] First prepare coarse syrup 1, then pump the coarse syrup to the syrup high level tank and mix it with the red sand back-dissolving syrup. At the same time, check and analyze the contents of various indicators of the mixed syrup. The result is: Brix 64.65°Bx, sulfur content Amount of 453mg / kg, depending on the purity of 89.12%, pH 6.93, and directly heat the crude syrup to 75-85°C with waste steam in the high-level syrup tank, and foam at a ratio of 8%, while adding 200ppm of phosphoric acid and 6 ppm of calcium saccharification. First reaction, then add flocculant 6ppm to carry out secondary reaction. After fully mixing, take samples before the secondary reactor flows into the floater. After flotation and separation by the buoyant device, various indicators of the floating clear syrup were inspected and analyzed, and the results were: Brix 63.42°Bx, sulfur content 271mg / kg, apparent purity 88.97%, pH value 6.68. The specific situation is as follows:

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com