Method for decolorization of sugar juice with water-soluble magnesium salt-lime

A water-soluble magnesium and sugar juice technology, applied in the purification of sugar juice, sugar production, application, etc., to achieve the effect of simple process, high decolorization rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

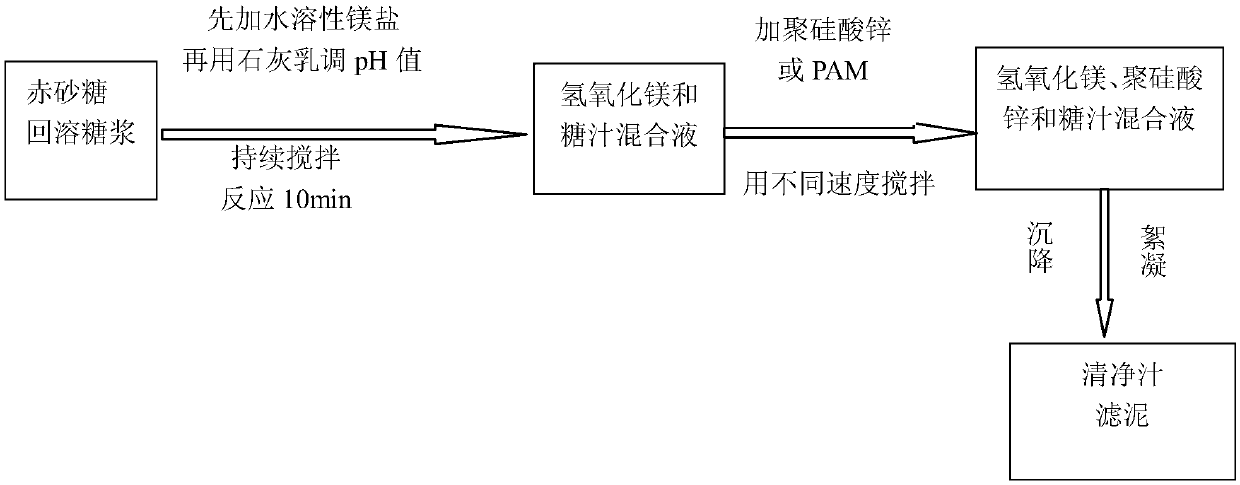

Method used

Image

Examples

Embodiment 1

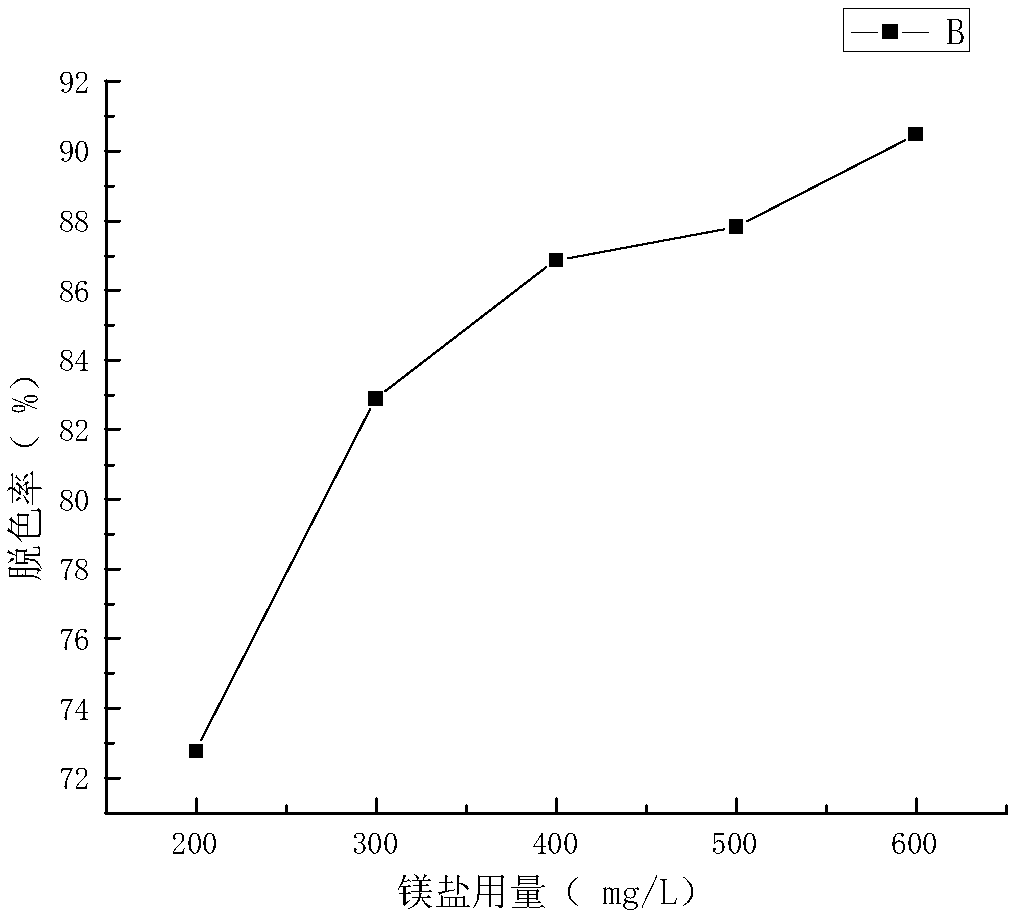

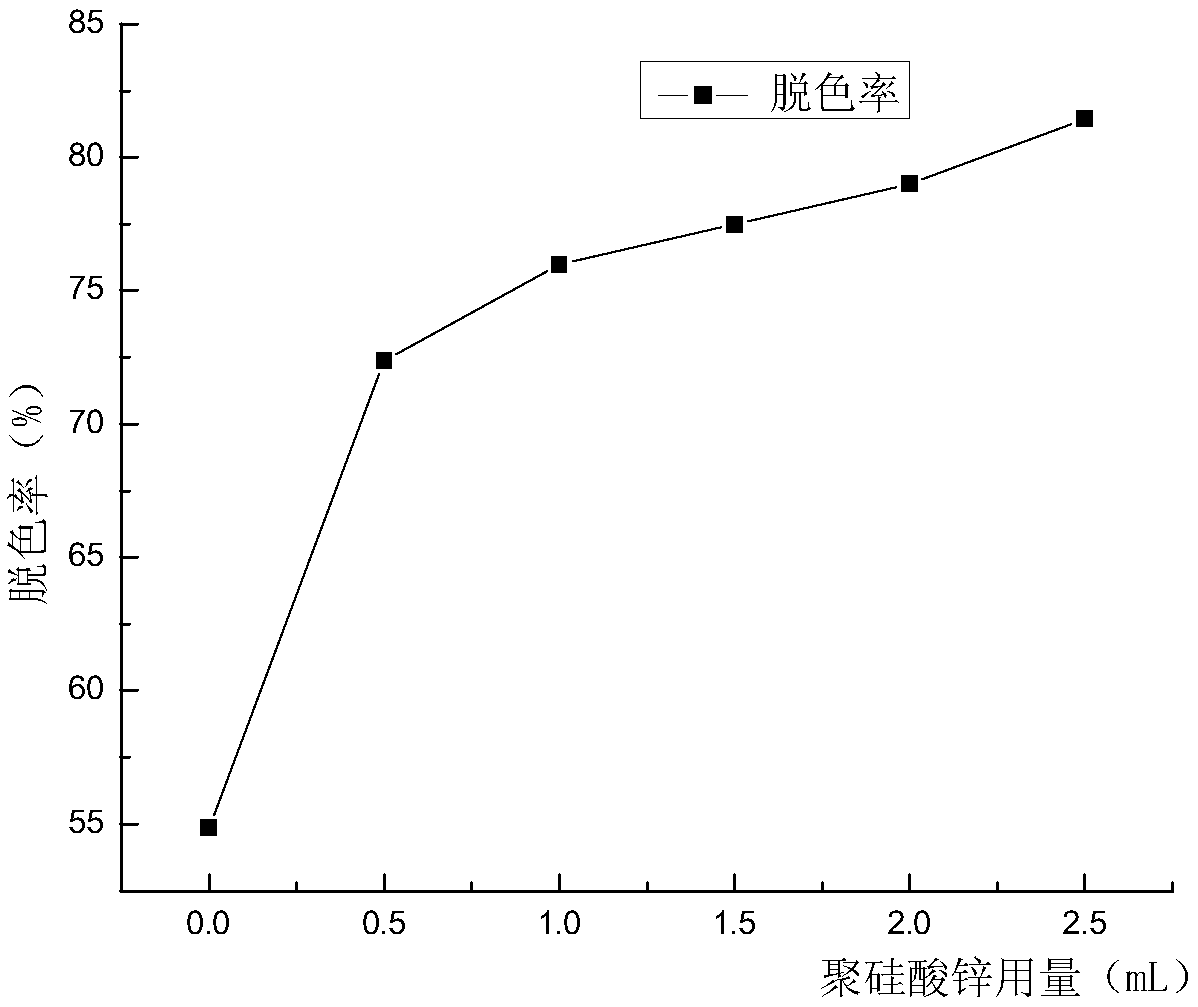

[0022] Example 1: Take 100 mL brown sugar redissolving syrup of 10°Bx in a 250mL beaker, add magnesium sulfate to make the magnesium ion content 500mg / L, then adjust the pH value to 11 with milk of lime, and keep it at 30°C After stirring for 10 minutes, add 2.5mL of zinc polysilicate with a mass concentration of 2% and stir rapidly (300r / min) for 30s, then switch to medium-speed stirring (200r / min) for 10min, and then switch to slow-speed stirring (30r / min) After 5 minutes, take out the beaker and place it at room temperature, and wait until the flocculation and sedimentation are stable to obtain clear juice, and the decolorization rate is 92.45%.

Embodiment 2

[0023] Example 2: Take 100 mL brown sugar redissolving syrup of 10°Bx in a 250mL beaker, add magnesium sulfate to make the magnesium ion content 500mg / L, then adjust the pH value to 11 with milk of lime, and keep it at 30°C After stirring for 10 minutes, add 2.2mL of zinc polysilicate with a mass concentration of 2% and stir rapidly (300r / min) for 30s, then switch to medium-speed stirring (200r / min) for 10min, and then switch to slow-speed stirring (30r / min) After 5 minutes, take out the beaker and place it at room temperature, and wait until the flocculation and sedimentation are stable to obtain clear juice, and the decolorization rate is 92.21%.

Embodiment 3

[0024] Example 3: Take 100 mL brown sugar redissolving syrup of 10°Bx in a 250mL beaker, add magnesium nitrate to make the magnesium ion content 450mg / L, then adjust the pH value to 11 with milk of lime, and keep at 30°C After stirring for 10 minutes, add 2.25mL of zinc polysilicate with a mass concentration of 2% and stir rapidly (300r / min) for 30s, then switch to medium-speed stirring (200r / min) for 10min, and then switch to slow-speed stirring (30r / min) After 5 minutes, take out the beaker and place it at room temperature, and wait until the flocculation and sedimentation are stable to obtain clear juice, and the decolorization rate is 91.32%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com