Device and process for treating membrane filtration concentrated liquor generated in membrane based sugar production

A treatment process and technology for concentrated liquid, which are applied in the production of sucrose, sugar production, purification of sugar juice, etc., can solve the problems of reducing the economic benefits of sugar mills, environmental pollution, etc., and achieve easy operation, improved economic benefits, and rich organic matter content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

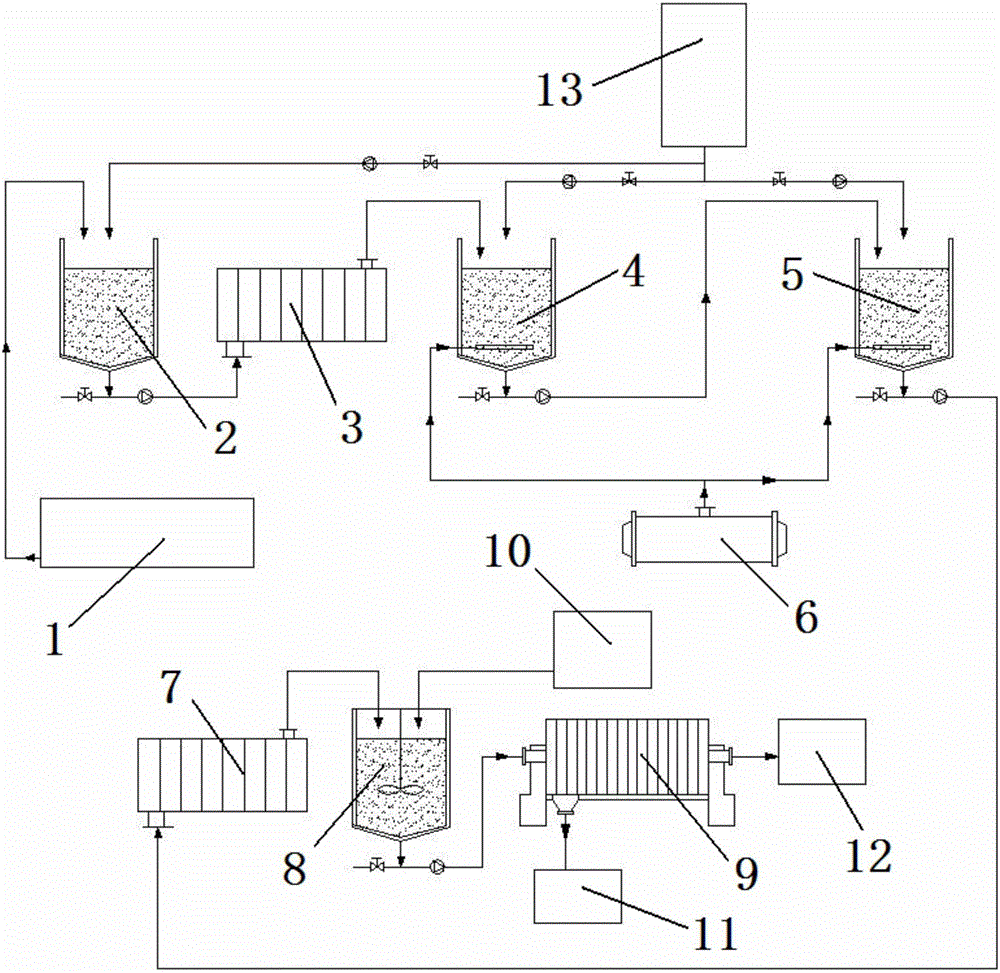

Method used

Image

Examples

Embodiment 1

[0023] A treatment process for membrane-based sugar membrane filtration concentrate, comprising the steps of:

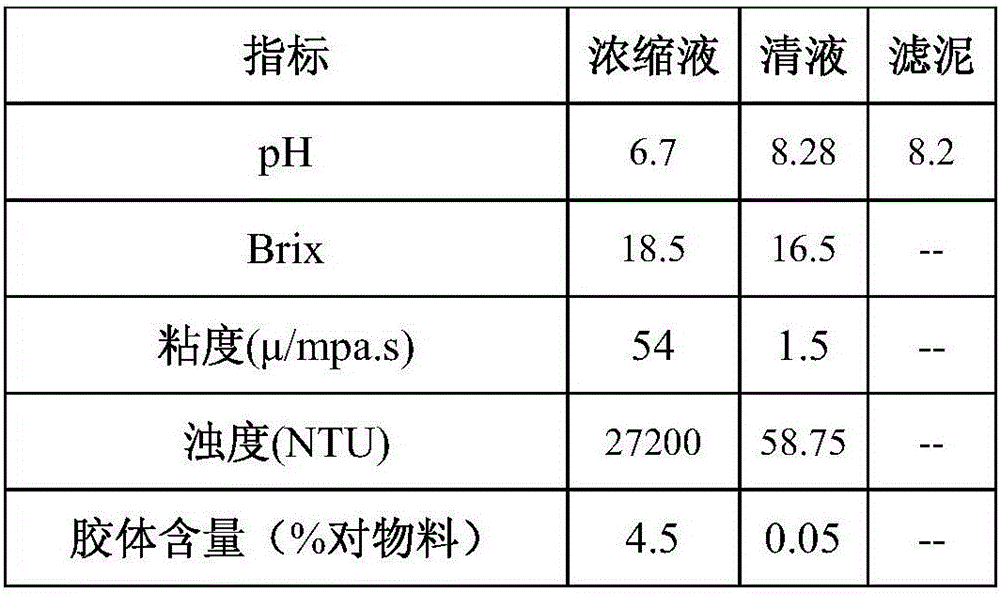

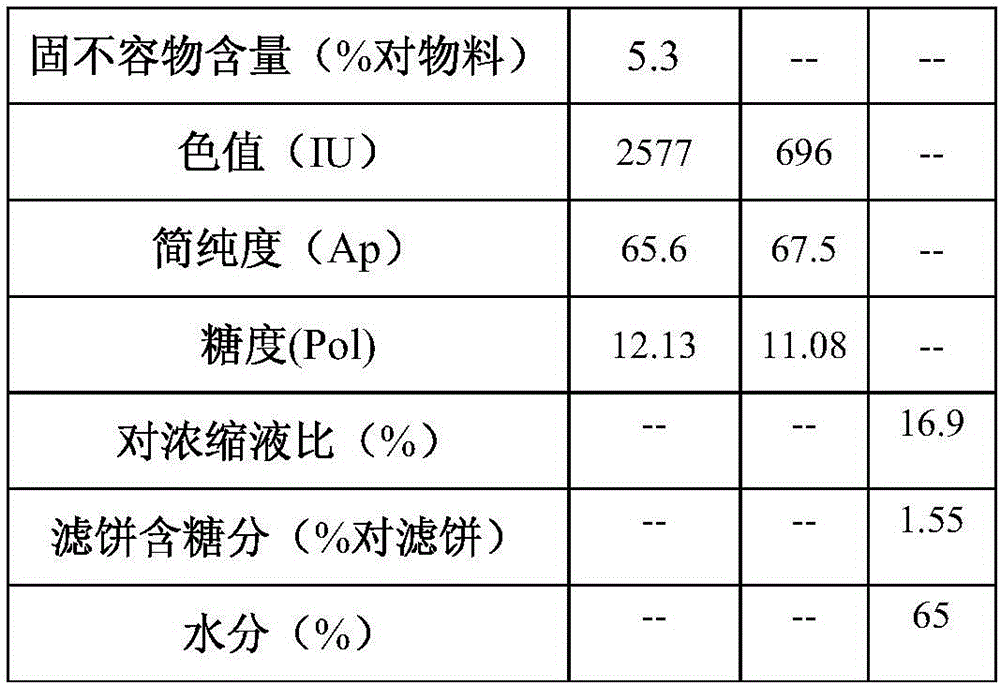

[0024] Take 1m of the membrane filtration concentrate with a volume concentration multiple of 10 3 , add milk of lime of 10°Be to the membrane filtration concentrate for the first time to adjust the pH to 7.0, then heat it to 45°C for the first time, then add milk of lime of 10°Be for the second time to adjust the pH to 11.2; Infuse carbon dioxide gas until pH = 8.3; add milk of lime for the third time to adjust pH to 11.2; pass in carbon dioxide gas for the second time until pH = 8.3; secondly heat to 70°C, and add 20kg sugar factory bagasse as a filter aid , stirred evenly, and pumped to a filter press for filtration to obtain filtrate and filter cake. In this embodiment, the total amount of milk of lime added is 1.6% of the weight of the membrane filtration concentrated solution.

[0025] The specific operation of the plate and frame filter press process is: pum...

Embodiment 2

[0032] Membrane sugar production and membrane filtration concentrated liquid treatment process, including the following steps: add milk of lime at 10 ° Be to the membrane filtered concentrated liquid with a volume concentration of 10 for the first time to adjust the pH to 7.0, and then heat it to 45 ° C for the first time, Then add milk of lime at 10°Be for the second time to adjust the pH to 11.2; for the first time, add carbon dioxide gas until pH = 8.3; add milk of lime for the third time to adjust the pH to 11.2; Heating to 70°C for the second time, adding 1.5% sugar bagasse as a filter aid, stirring evenly, and pumping to a filter press for filtration to obtain filtrate and filter cake.

[0033] The specific operation of the plate and frame filter press process is: pump the heated and saturated material after adding filter aids to the plate and frame filter press for press filtration. The sugar content of the filter cake is washed with water, the water temperature is 55°C...

Embodiment 3

[0038] Membrane sugar production and membrane filtration concentrated liquid treatment process, including the following steps: add milk of lime at 10 ° Be to the membrane filtered concentrated liquid with a volume concentration of 10 for the first time to adjust the pH to 7.0, and then heat it to 45 ° C for the first time, Add milk of lime at 10°Be for the second time to adjust the pH to 10.5; for the first time, pass carbon dioxide gas until pH = 8.3; add milk of lime for the third time to adjust the pH to 10.5; pass carbon dioxide gas for the second time until pH = 8.3 Heating to 70°C for the second time, adding 2% sugar bagasse as a filter aid, stirring evenly, pumping to a filter press for filtration, and obtaining filtrate and filter cake.

[0039] The total addition of the milk of lime is 1.3% of the concentrated solution weight in step (1).

[0040]The specific operation of the plate and frame filter press process is: pump the heated and saturated material after adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com