Production processing method of refined full-sucrose syrup and production processing equipment thereof

A technology of processing equipment and processing methods, which is applied in the directions of sucrose production, sugar production, and juice purification, etc., can solve the problems of influence of syrup quality, high production and processing costs, complicated processing steps, etc., so as to shorten the production and processing flow, reduce Production and processing costs, the effect of low heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

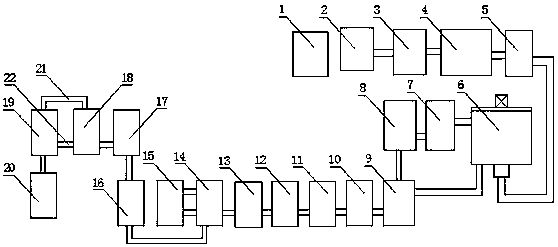

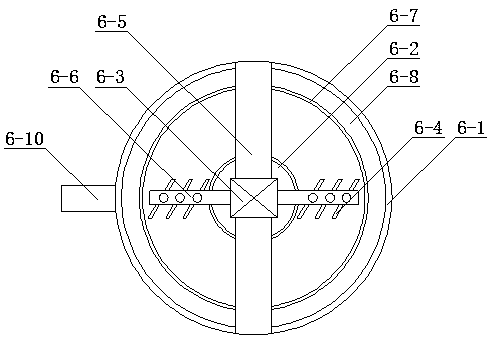

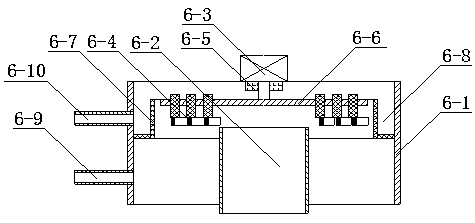

[0032] Such as figure 1 , figure 2 , image 3 As shown, the production and processing method of a kind of refined whole sucrose syrup described in this embodiment, the steps are as follows:

[0033] The first step, neutralization adjustment treatment: transport the primary product of sugar juice to the adjustment tank for neutralization reaction, that is, add 4.5 kg of phosphoric acid with a concentration of 10% and 11 kg of phosphoric acid with a concentration of 10% to each ton of primary product of sugar juice 5 minutes of neutralization reaction for 8% milk of lime;

[0034] The second step, buffer mixing treatment: heat the initial sugar juice after neutralization reaction to 75°C and buffer for 15 minutes, then fill it with fine and uniform bubbles through a bubble maker, and then add 22 kg of flocculant with a concentration of 0.05% 25 minutes of mixed trea...

Embodiment 2

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

[0047] Such as figure 1 , figure 2 , image 3 As shown, the production and processing method of a kind of refined whole sucrose syrup described in this embodiment, the steps are as follows:

[0048] The first step, neutralization adjustment treatment: transport the primary product of sugar juice to the adjustment tank for neutralization reaction, that is, add 5 kg of phosphoric acid with a concentration of 10% and 10 kg of phosphoric acid with a concentration of 10% to each ton of primary product of sugar juice 10 minutes of neutralization adjustment for 8% milk of lime;

[0049] The second step, buffering and mixing treatment: heat the first product of the neutralized and adjusted sugar juice to 85°C and buffer for 20 minutes, then fill it with fine and uniform bubbles through the bubble maker, and then add 23 kg of flocculant with a concentration of 0.05% 15 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com