Technique for glycosylated degradation of white spirit waste lees to prepare fermentalbe sugar

A technology for fermenting sugar and liquor, which is applied in the field of saccharification and degradation of liquor and discarded grains, efficient saccharification and degradation of liquor and discarded grains to prepare fermentable sugar, and can solve the problems of low utilization rate, no formation of liquor and discarded grains, etc., and achieves high recovery rate and reduced production. The effect of low cost and separation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The distilled grains used in this example are secondary distilled grains provided by Wuliangye Distillery in my country; the model of the anion exchange resin used is D301 macroporous weak base anion exchange resin.

[0031] (1) Drying of waste:

[0032] 100g of fresh secondary liquor fermented with 65.5% water content, 16.91% crude starch, 22% crude fiber, and 15.62% ash, dried at 90°C, and the water content was determined to be 6%. Crush to make fine powder, store in a dry and cool place for later use;

[0033] (2) Throwing grains into fine pulverization:

[0034] Pass 30 g of the above-mentioned dregs powder after drying and crushing through a 40-mesh sieve, and the sieving ratio is 92.65%;

[0035] (3) Dilute hydrochloric acid saccharification degradation:

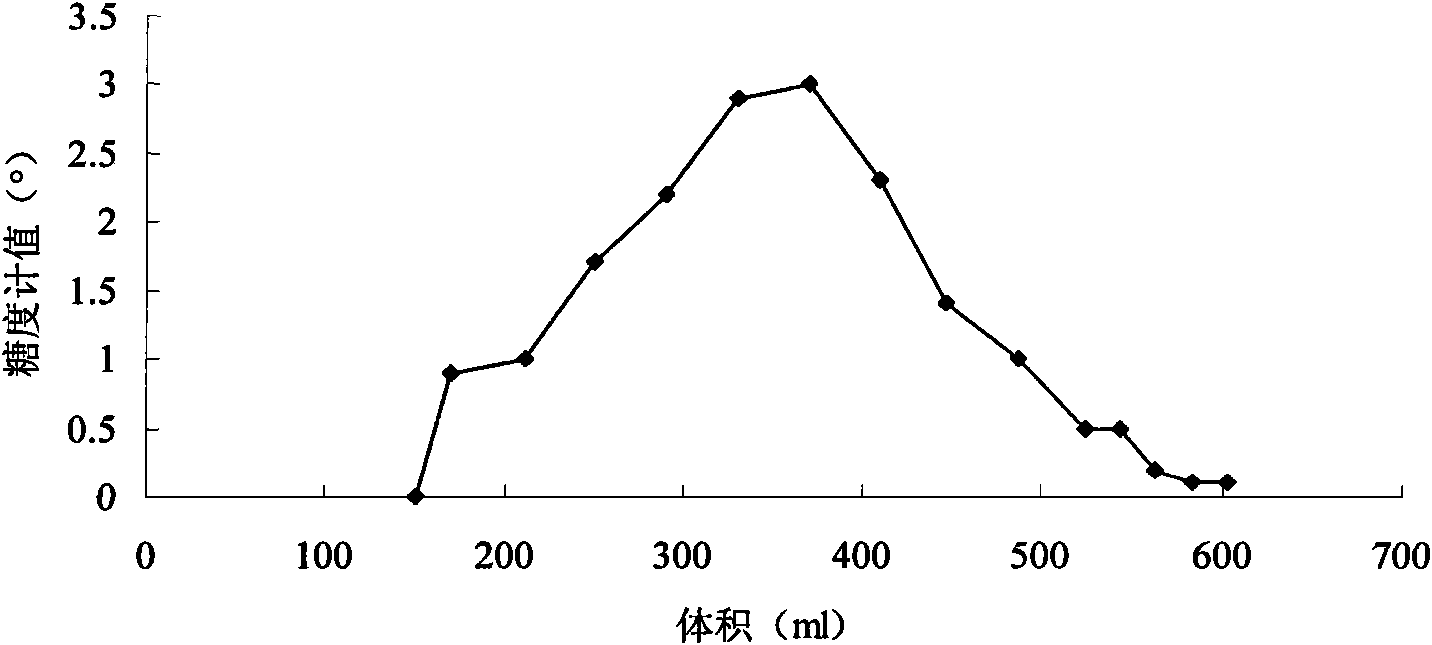

[0036] Weigh 25 g of the above-mentioned distilled grains powder and 2% hydrogen chloride (HCl) with a mass fraction of 2%, mix the mixture according to the ratio of mass volume ratio of 1:10, saccharify and ...

Embodiment 2

[0042] The distilled grains of liquor used in this example are the one-time distilled grains of liquor provided by Quanxing Distillery in my country; the model of the anion exchange resin used is D301 macroporous weak base anion exchange resin.

[0043] (1) Drying of waste:

[0044] Take 100g of primary liquor distilled grains with water content of 65%, crude starch 18.05%, crude fiber 35.43%, ash content 13.48%, dry at 90°C until the water content is about 5%, and pulverize it to make distilled grains fine powder , stored in a dry and cool place for later use;

[0045] (2) Finely pulverize the grains;

[0046] Pass through a 40-mesh sampling sieve through 30 g of dried and pulverized dregs powder, and the sieve ratio is 94.52%;

[0047] (3) Dilute hydrochloric acid saccharification degradation:

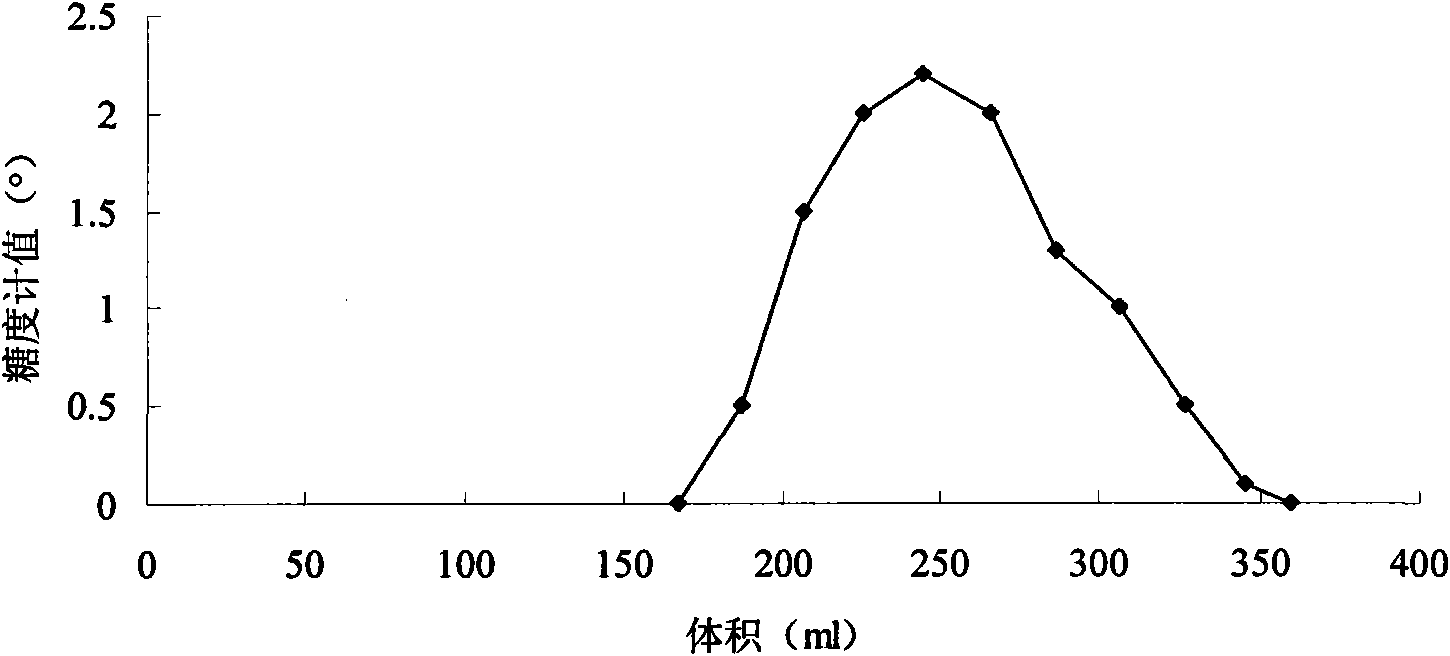

[0048] Weigh 10 g of the above-mentioned discarded grain powder and 2% hydrogen chloride (HCl) by mass fraction, mix them according to the ratio of mass volume ratio 1:10 to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com