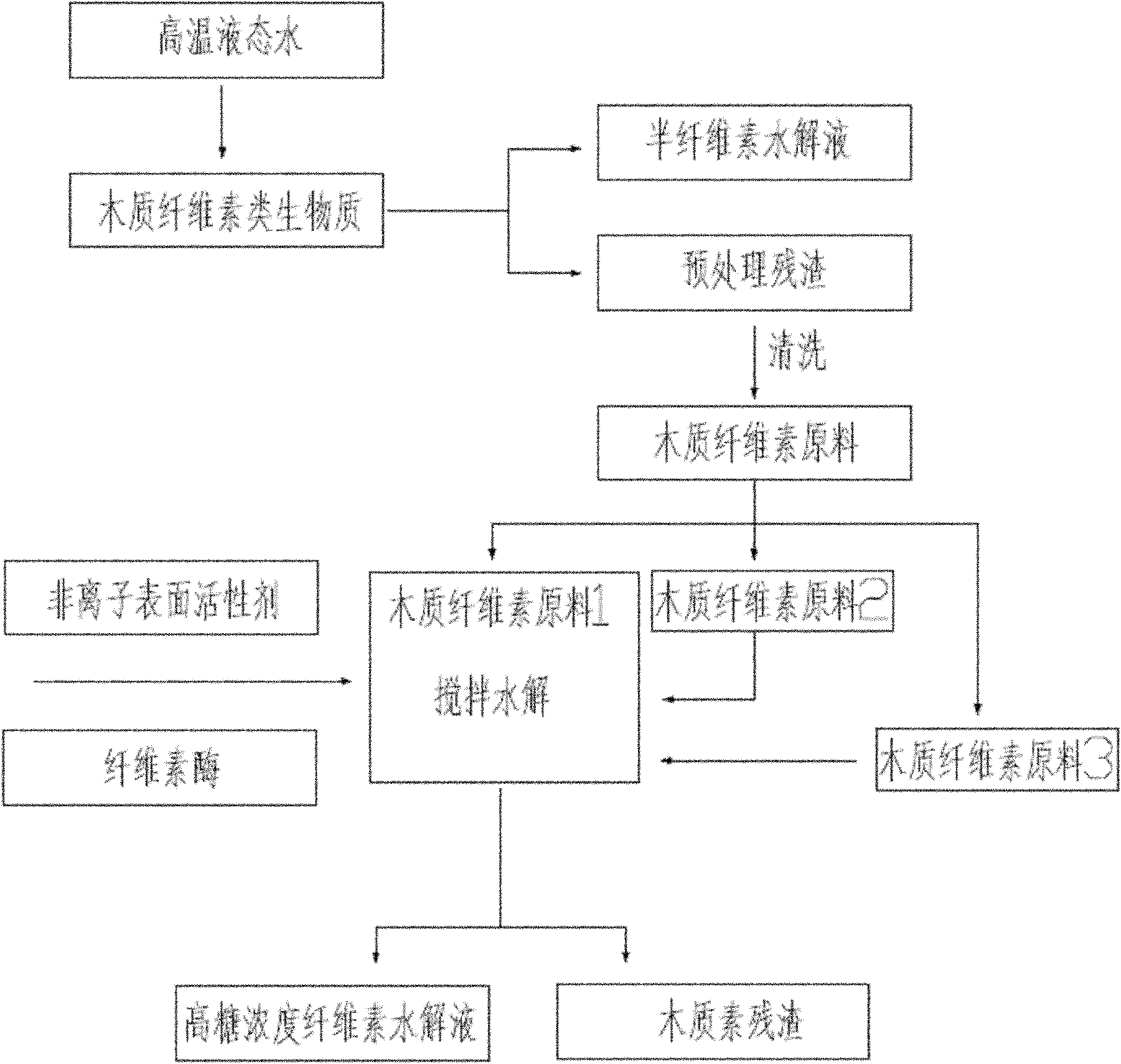

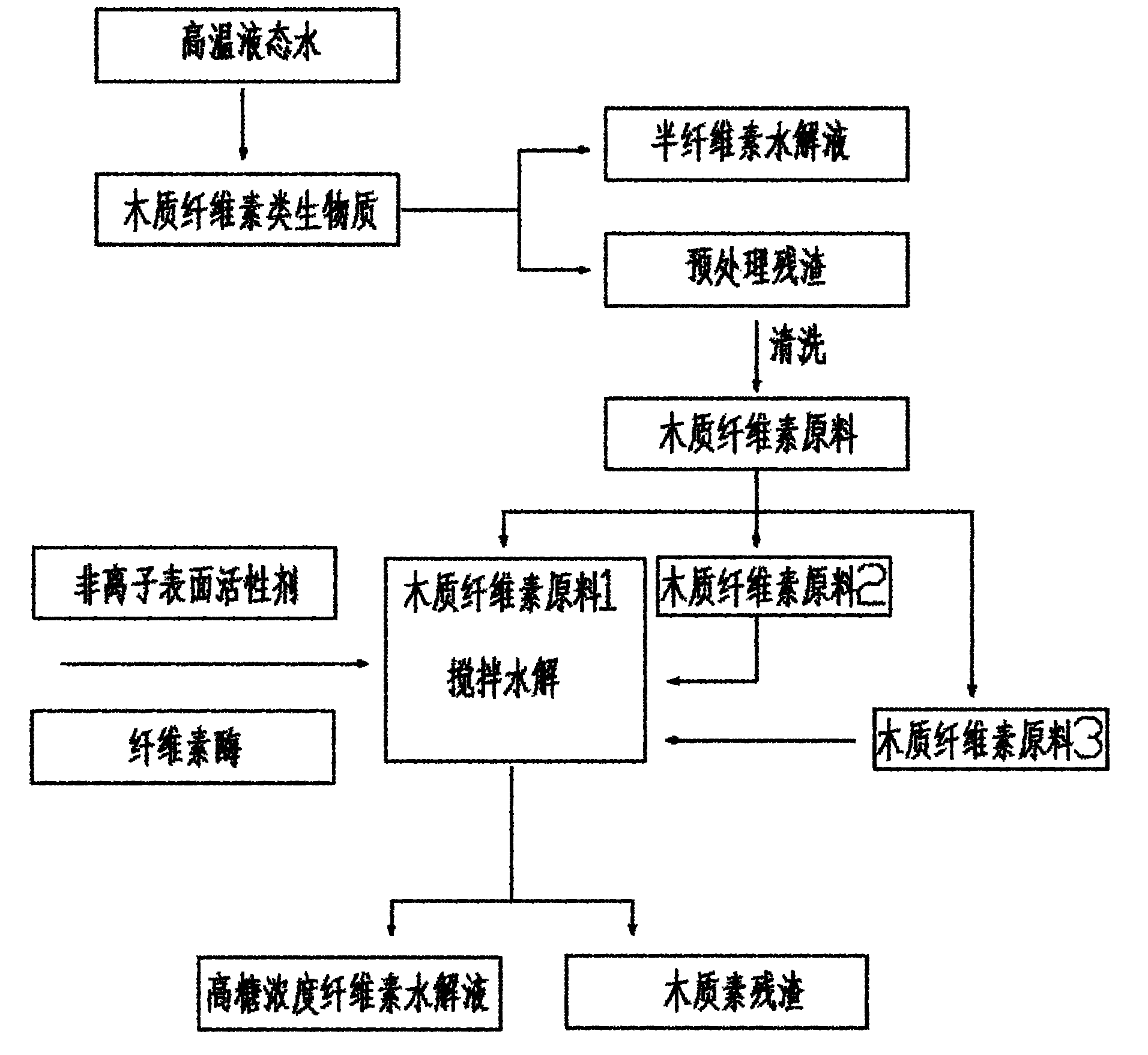

Efficient enzyme hydrolysis method of lignocellulose biomass

A lignocellulosic and lignocellulose technology, which is applied in the field of lignocellulose hydrolysis and high-efficiency enzymatic hydrolysis of lignocellulosic biomass, to achieve the effects of increasing the concentration of enzymatic hydrolysis raw materials, high hydrolysis efficiency, and high sugar production concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Crush the sugar-free sweet sorghum stalk residue after squeezing to 40 mesh, and add it to the high-temperature liquid water reaction kettle according to the ratio of solid-liquid ratio of 1:10g / mL. , processing for 15 minutes, completing pretreatment, solid-liquid separation, and obtaining hemicellulose hydrolyzate and pretreated sweet sorghum stalk residue substrate. Wash with clean water to remove enzyme hydrolysis and fermentation inhibitors, and use it as raw material for enzyme hydrolysis. Take 1 g of sweet sorghum stalk substrate as raw material for enzymatic hydrolysis, add 10 mL of 0.05 M acetic acid-sodium acetate buffer solution (pH 4.5), add cellulase at a ratio of 10 FPU / g cellulose or dextran, and add 0.075 mL Tween80, stirred and hydrolyzed at 45°C for 12 hours, then added 0.5 g of sweet sorghum stalk substrate, added cellulase at a ratio of 10 FPU / g dextran, and added 0.0375 mL Tween80 at the same time, stirred and hydrolyzed for 36 hours, then added Ad...

Embodiment 2

[0035] Crush the sweet sorghum stalk residue after squeezing to 60 mesh, add it to the high-temperature liquid water reactor at a solid-to-liquid ratio of 1:20 g / mL, and treat it for 30 minutes in a high-temperature liquid water environment of 4Mpa, 190°C, and 500rpm to complete Pretreatment, solid-liquid separation, obtain hemicellulose hydrolyzate and pretreated sweet sorghum stalk substrate, wash with water, remove enzyme hydrolysis and fermentation inhibitors, and use it as raw material for enzyme hydrolysis. Take 1.5g as raw material for enzymatic hydrolysis, add 10mL 0.1M acetic acid-sodium acetate buffer (pH4.8), add cellulase at a ratio of 20FPU / g dextran, and add 0.3mL Tween80 at the same time, magnetically After stirring and hydrolyzing for 24 hours, add 0.75g of substrate, add cellulase at the ratio of 20FPU / g dextran, and add 0.15mL Tween80 at the same time, after magnetic stirring and hydrolyzing for 48h, then add 0.75g of pretreatment material, and then add 0.75g ...

Embodiment 3

[0037] The sweet sorghum stalk residue after squeezing the juice was crushed to 60 mesh, and added to the high-temperature liquid water reaction kettle according to the solid-liquid ratio of 1:20g / mL, and treated in the high-temperature liquid water environment of 4Mpa, 180°C, and 400rpm for 20min, and the pre-treatment was completed. treatment and solid-liquid separation to obtain hemicellulose hydrolyzate and pretreated sweet sorghum stalk substrate, washed with water to remove enzyme hydrolysis and fermentation inhibitors, and used as raw materials for enzyme hydrolysis. Take 1g as raw material for enzymatic hydrolysis, add 10mL 0.05M acetic acid-sodium acetate buffer (pH4.8), add cellulase at a ratio of 20FPU / g dextran, and add 0.075mL / g Tween80 at the same time, at 50℃ After 24 hours of magnetic stirring and hydrolysis, add 0.5g of pretreatment material, add cellulase at a ratio of 20FPU / g dextran, and add 0.0375mL Tween80 at the same time, after magnetic stirring and hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com