Method for improving cellulase hydrolysis sugar field

A cellulase and cellulose technology, applied in fermentation and other directions, can solve the problems of high purification and recycling costs and high solvent costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

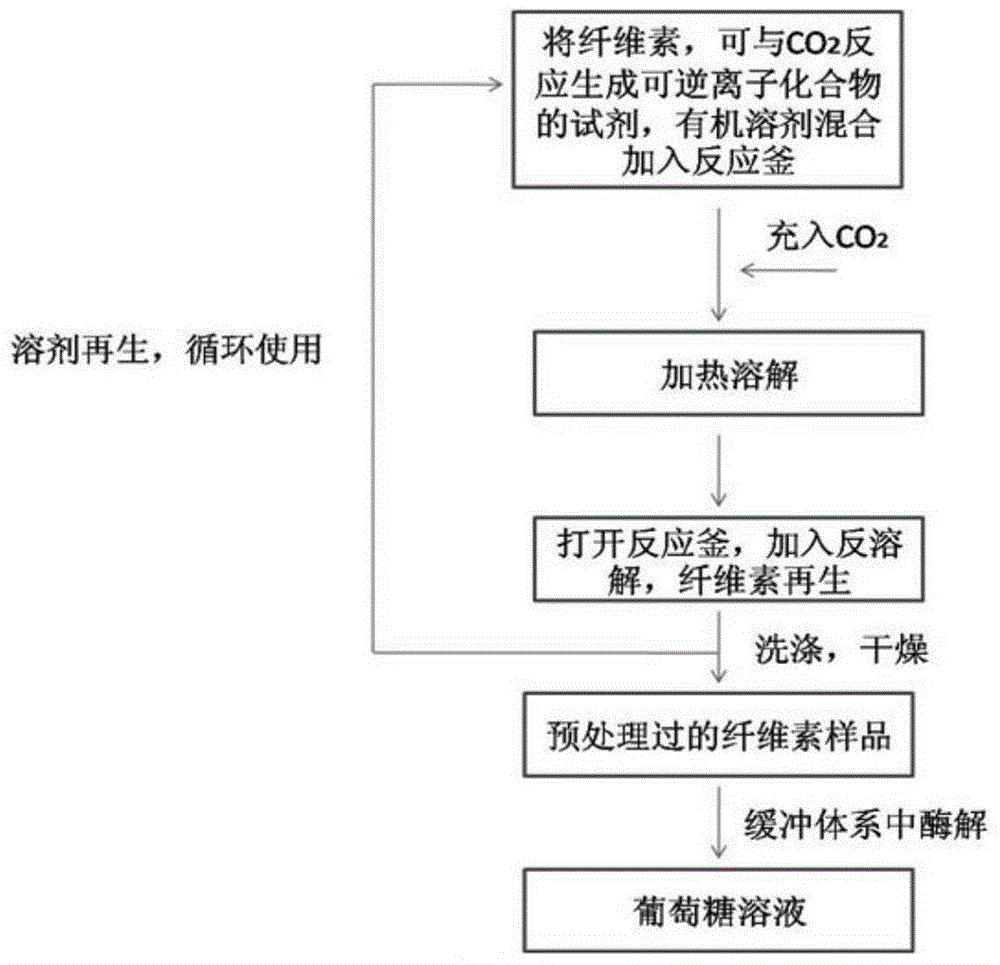

[0059] figure 1 It is a schematic flow chart of a method for improving the sugar production rate of cellulose enzymatic hydrolysis provided by the present invention. Such as figure 1 As shown, it is carried out according to the following steps:

[0060] 1. Using cellulose as raw material;

[0061] 2. Will be available with CO 2 One or two or more compound raw materials in the Switchable ionic compounds (Switchable ionic compounds) are mixed with cellulose to form a pre-dissolved system;

[0062] or will be available with CO 2 One or two or more compound raw materials in the switch-type ionic compound formed by reaction are mixed with cellulose and an organic solvent with good swelling effect on cellulose to form a pre-dissolved system;

[0063] or CO 2 One or more of Switchable ionic compounds are mixed with cellulose to form a pre-dissolved system;

[0064] or CO 2 One or two or more of the switch-type ionic compounds are mixed with cellulose and an organic solvent ...

Embodiment 2

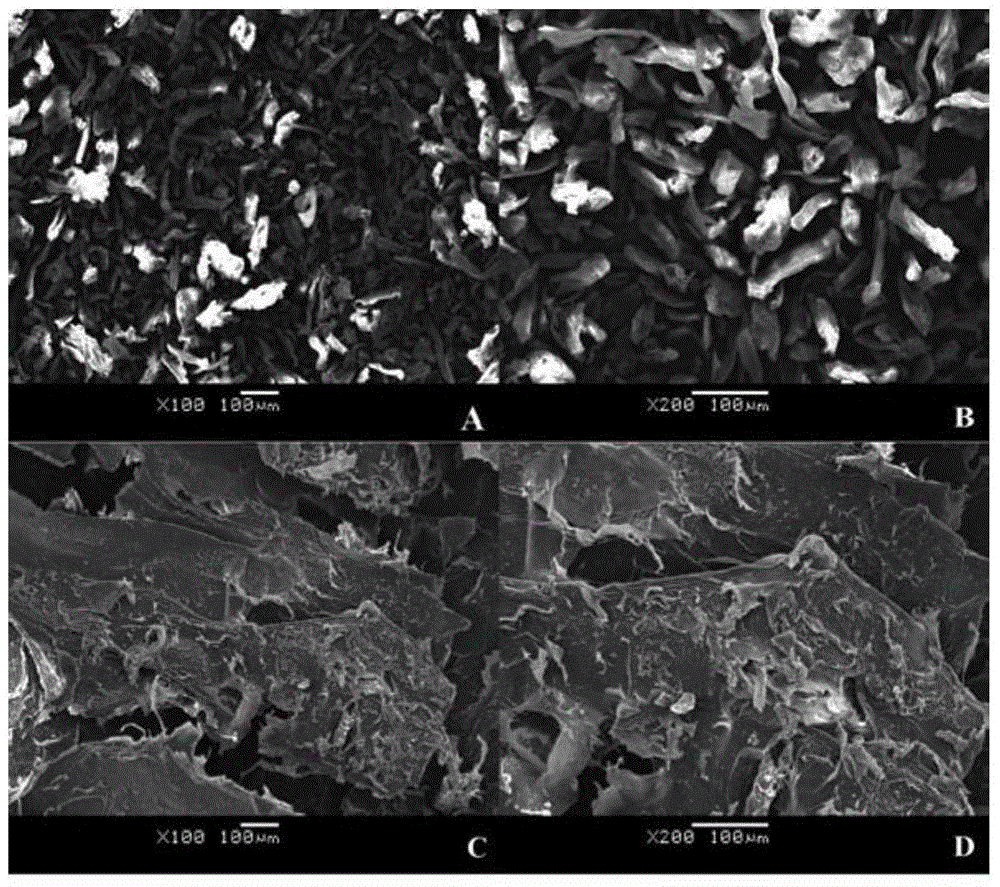

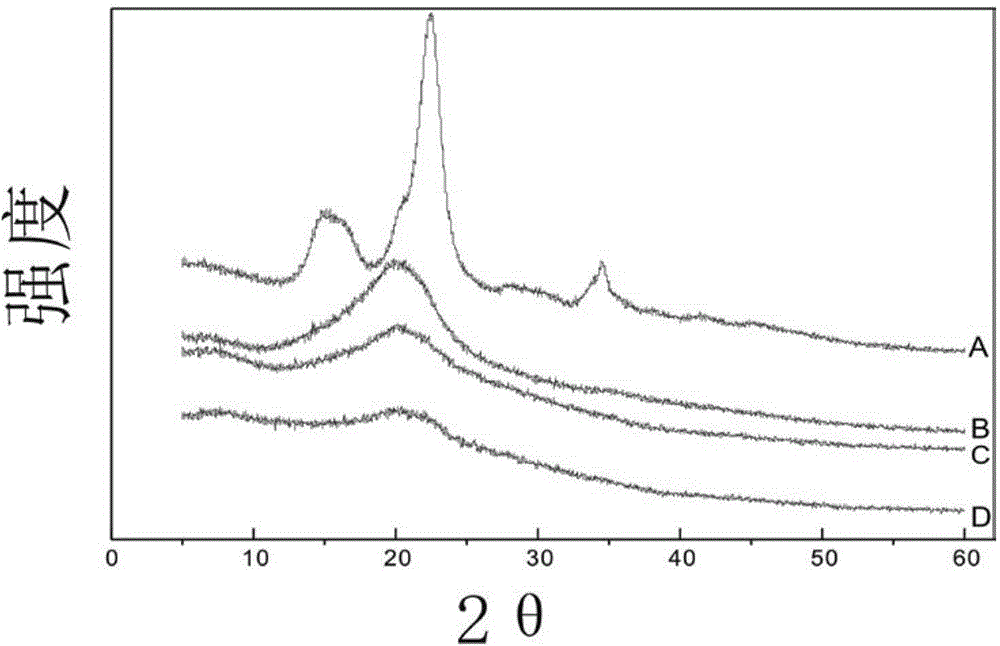

[0070] Mix methanol (0.039 mol, 0.8 g), tetramethylguanidine (0.039 mol, 4.5 g), DMSO (12.2 g), and 2.0 g of corn stalk cellulose, add to the autoclave, close the lid tightly, and pass in CO 2 , maintain the pressure at 0.2MPa, heat to 50°C, and dissolve for 60 minutes. cool down, releasing CO 2 , Open the reaction kettle, add 100ml of anhydrous methanol to the system under stirring conditions, regenerate the dissolved cellulose, filter, and collect the filtrate. Then the filter residue was washed with 2*100ml of anhydrous methanol, each time for 1h, to completely remove the solvent, and then dried to obtain dissolved pretreated cellulose. Filtrate, collect filter residue, and freeze-dry to obtain regenerated cellulose. Using regenerated cellulose as raw material, add acetic acid-sodium acetate buffer solution, the solid-to-liquid ratio is 1:10, the amount of Trichoderma viride is 15 FPU / g, the shaking table speed is 100 rpm, and the enzymatic hydrolysis condition is pH4.5. ...

Embodiment 3

[0072] Ethylene glycol (0.018 moles, 1.14 grams), tetramethylguanidine (0.036 moles, 4.14 grams), DMSO (12.7 grams), and 1.0 grams of microcrystalline cellulose were mixed, added to the autoclave, and the lid was tightly closed. Into CO 2 , maintain the pressure at 0.2MPa, heat to 50°C, and dissolve for 60 minutes. cool down, releasing CO 2 , Open the reaction kettle, add 100ml of anhydrous methanol to the system under stirring conditions, regenerate the dissolved cellulose, filter, and collect the filtrate. Then the filter residue was washed with 2*100ml of anhydrous methanol, each time for 1h, to completely remove the solvent, and then dried to obtain dissolved pretreated cellulose. Filtrate, collect filter residue, and freeze-dry to obtain regenerated cellulose. Regenerated cellulose was used as raw material, citric acid-sodium citrate buffer solution was added, the solid-to-liquid ratio was 1:20, the amount of Trichoderma viride was 20 FPU / g, the shaking table speed was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com