Novel method for saccharification of ligno-cellulose

A technology of lignocellulose and saccharification treatment, applied in biofuels, fermentation, etc., can solve the problems of high production cost, increased production cost, high corrosion resistance requirements, etc., to achieve increased contact specific surface area, equipment loss and low cost, The effect of eliminating individual differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The corn stover is crushed to a particle size of 0.5 mm. Take 3.00g of crushed raw materials and add 45mL H + After soaking in HCl solution with a concentration of 0.1mol / L for 8 hours at room temperature, use planetary ball mill, 60mL agate ball mill, rotating speed 340r / min, filling rate of agate grinding ball is 10%, alternating operation interval 3min, ball milling 15min; After the raw materials are ball milled, they are neutralized with a 10% NaOH solution, filtered and washed with water, and the washing liquid is collected to obtain an acid hydrolyzed sugar solution.

[0069] Select the cellulase and xylase for compounding:

[0070] A. Cellulase Accellerase 1000 (purchased from Genencor International)

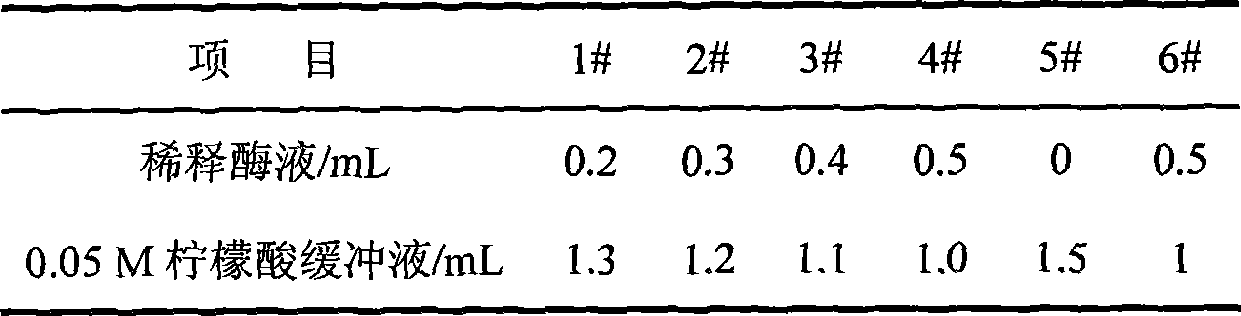

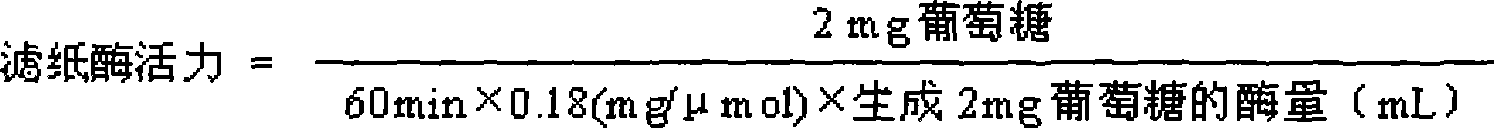

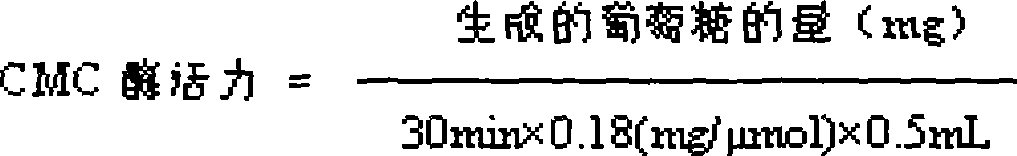

[0071] The result of enzyme activity determination is ( / mL cellulase): filter paper enzyme activity 93FPIU, CMC enzyme activity 7.38IU, β-glucosidase activity 1632.9IU;

[0072] B. Cellulase ZSL-1300 (Shandong Zesheng Biotechnology Company)

[0073] The result of enzym...

Embodiment 2

[0079] The sawdust is crushed to a particle size of 0.5 mm. Take 3.00g crushed raw materials and add 30mL H + H at a concentration of 0.01mol / L 2 SO 4 After the solution is soaked at room temperature for 12 hours, use a planetary ball mill, 60mL agate ball milling tank, rotating speed 340r / min, agate ball filling rate of 50%, alternating operation interval 3min, ball milling for 30min; after the raw material is ball milled, use 10% Ca( OH) 2 After the solution is neutralized, it is filtered and washed with water, and the washing liquid is collected to obtain the acid hydrolyzed sugar liquid.

[0080] Select the cellulase and xylase for compounding:

[0081] A. Cellulase R-10 (purchased from Shanghai Kaiyang Biotechnology Co., Ltd.)

[0082] The result of enzyme activity measurement is ( / g cellulase): filter paper enzyme activity 9FPIU, CMC enzyme activity 24IU, β-glucosidase activity 859IU;

[0083] B. Cellulase (purchased from Wuxi Gaorunjie Biological Engineering Co., Ltd.)

[00...

Embodiment 3

[0092] The coconut shell is crushed to a particle size of 2.5mm. Take 160.0g crushed raw materials and add 800mL H + H at a concentration of 0.01mol / L 2 SO 4 After soaking at room temperature for 4h, use planetary ball mill, 1000mL agate ball mill, rotate speed 390r / min, fill rate of agate ball is 50%, alternate operation interval 3min, ball mill for 15min; after ball milling, use 10% KOH solution After mixing, it is filtered and washed with water, and the washing liquid is collected to obtain an acid hydrolyzed sugar solution.

[0093] Select the cellulase and xylase for compounding:

[0094] A. Cellulase Accellerase 1000 (purchased from Genencor International)

[0095] The result of enzyme activity determination is ( / mL cellulase): filter paper enzyme activity 93FPIU, CMC enzyme activity 7.38IU, β-glucosidase activity 1632.9IU;

[0096] B. Cellulase (purchased from Wuxi Gaorunjie Biological Engineering Co., Ltd.)

[0097] The result of enzyme activity determination is ( / g cellul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com