A continuous preparation of boron-doped SiO 2 Airgel method

An aerogel and boron doping technology, which is applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of affecting the physical properties of silica aerogels, greatly affecting the thermal conductivity, and low porosity, achieving The effect of good light transmission, high continuity and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

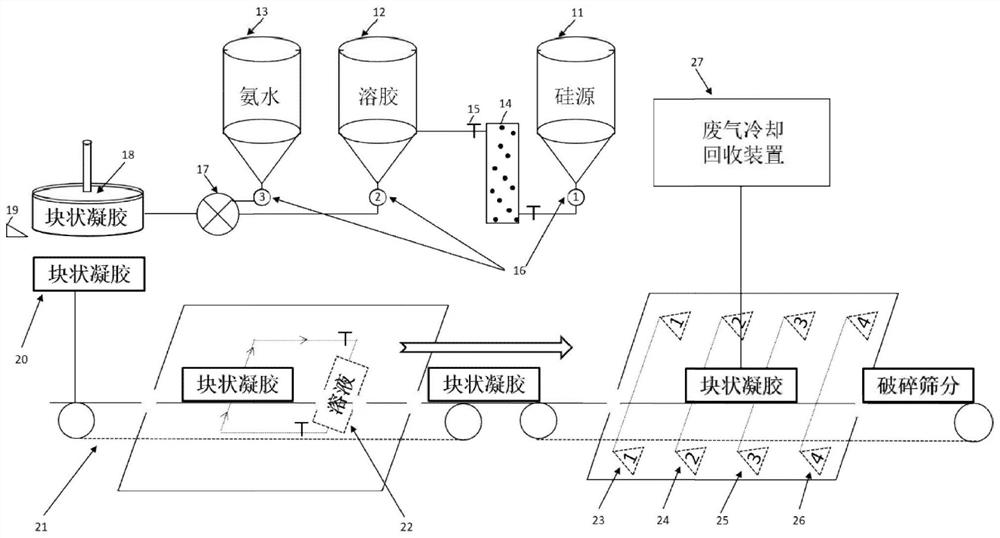

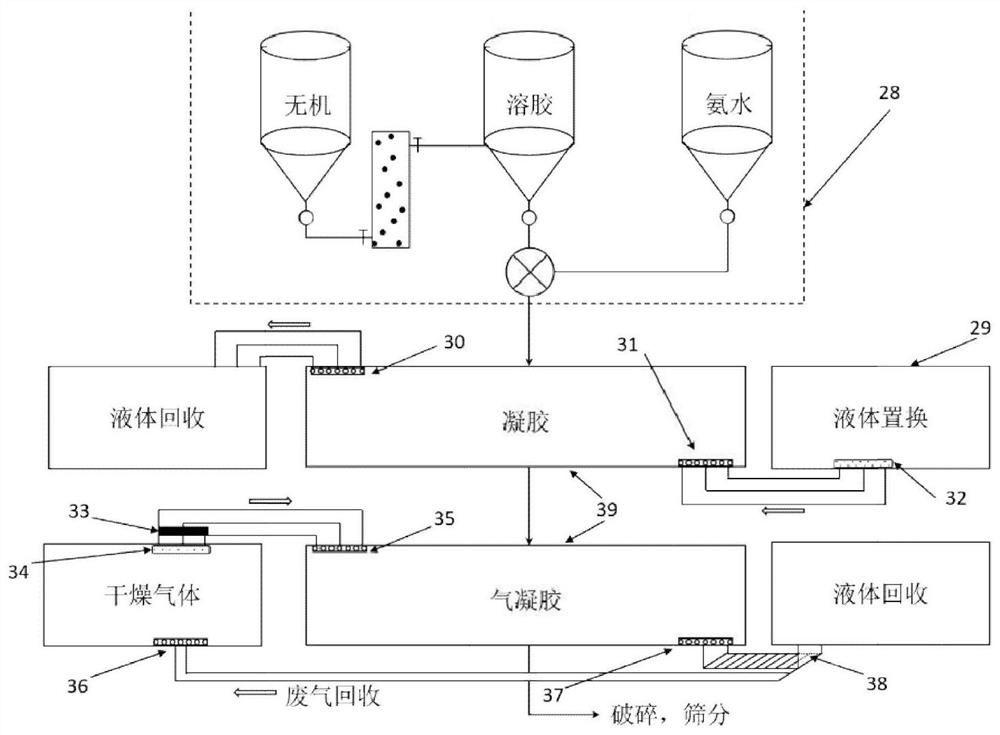

Method used

Image

Examples

Embodiment 1

[0057] Take the modulus as 3.2, SiO 2 Content is 2842g of water glass of 72.14%, and with water glass, deionized water according to the ratio of molar ratio is 1:15 mixes evenly, carries out ion removal by cation exchange resin device, obtains silicic acid sol, then adds dehydrated alcohol, Methyltriethoxysilane, boric acid and hydrochloric acid solution are mixed, and the overall molar ratio of industrial water glass, deionized water, hydrochloric acid, boric acid, absolute ethanol and methyltriethoxysilane is 1:15:0.001:0.001: 10:0.1. After uniform mixing, measure the pH value of the mixed solution at this time to be 3.4, and let it stand for 1 hour. The amount of ammonia added is 5% of the molar amount of water glass, which is diluted and slowly added to the mixed sol, stirred while adding, and the amount of ammonia added is controlled by a flow rate meter. Carry out post-treatment of the gel according to the process of process 1. After the gel reaction occurs, extrude t...

Embodiment 2

[0059] Take the modulus as 3.2, SiO 2 Content is 2842g of water glass of 72.14%, and water glass, deionized water are mixed evenly according to the ratio of 1:10 according to molar ratio, carries out ion removal by cation exchange resin device, obtains silicic acid sol, then adds dehydrated alcohol, Methyltriethoxysilane, boric acid and hydrochloric acid solution are mixed, and the overall molar ratio of industrial water glass, deionized water, hydrochloric acid, boric acid, absolute ethanol and methyltriethoxysilane is 1:10:0.1:0.1: 10:1. After uniform mixing, measure the pH value of the mixed solution at this time to be 1.8, and let it stand for 1 hour. The amount of ammonia added is 25% of the molar weight of water glass, which is diluted and slowly added to the mixed sol, stirred while adding, and the amount of ammonia added is controlled by a flow rate meter. After the gel reaction occurs, follow-up treatment is carried out according to the process of process 2. Put th...

Embodiment 3

[0061] Take the modulus as 3.2, SiO 2 Content is 2842g of water glass of 72.14%, and with water glass, deionized water according to the ratio that molar ratio is 1:30, mixes evenly, carries out ion removal by cation exchange resin device, obtains silicic acid sol, then adds dehydrated alcohol, Methyltriethoxysilane, boric acid and hydrochloric acid solution are mixed, and the overall molar ratio of industrial water glass, deionized water, hydrochloric acid, boric acid, absolute ethanol and methyltriethoxysilane is 1:30:0.01:0.5: 30:0.5. After uniform mixing, measure the pH value of the mixed solution at this time to be 3.6, and let it stand for 1 hour. The add-on of ammonia water is 16.8% of the molar weight of water glass, it is slowly added in the mixed sol after diluting, stirs while adding, controls the add-on of ammonia water by flow velocity meter. After the gel reaction occurs, process 1 is used to carry out subsequent treatment on the gel. Extrude the gel into the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com