Process for producing high-safety white granulated sugar

A high-safety white granulated sugar technology, applied in sucrose production, sugar production, sugar juice purification, etc., can solve the problems of low clarity of clear juice, complicated process, low production efficiency, etc., to reduce labor costs, operate Simple, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

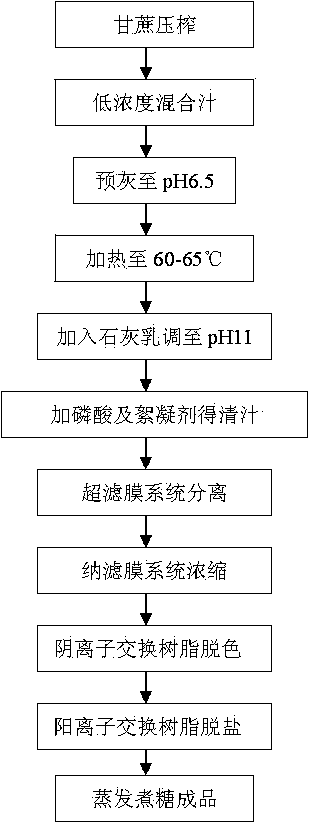

[0029] Attached below figure 1 And embodiment further describe the present invention.

[0030] Take the organic sugarcane and squeeze it to get the mixed juice, prelime the mixed juice to pH6.5, heat it to 60-65℃ once, then add lime milk to adjust the pH to 11, and add 100-300ppm phosphoric acid and 1-3ppm polypropylene The amide flocculant fully reacts and separates scum in the floater to obtain clear juice and mud juice. The colloidal organic matter in the clear juice is removed by more than 50%, the turbidity is reduced from 2800IU to 870IU, and the gravity purity of the clear juice is 2.4GP higher than that of the mixed juice. Take 50kg of clear juice and use the ultrafiltration membrane experimental equipment to circulate for 10 minutes, boost the pressure to 0.4MPa and filter through the ultrafiltration membrane to obtain 38.33kg of light yellow clear and transparent filtrate and 11.67kg of light brown thick liquid. With the increase of the impurity concentration in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com