Method for recovering waste water generated in production of starch sugar

A technology for producing waste water and recycling methods, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of waste of water resources, large consumption of water resources, etc., and achieve production The effect of large water volume, saving water treatment cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

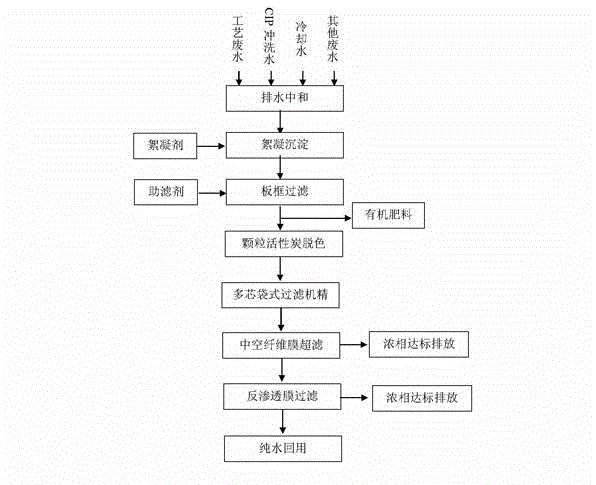

[0021] The waste water treatment and recovery process of fructose syrup production is as follows:

[0022] 1. 200 tons of production wastewater, the measured initial conductivity is 2482μs / cm, pH is 5.32, COD is 3500mg / L, and sodium hydroxide is added to adjust the pH to 6.5.

[0023] 2. Add 35mg / L of polyaluminum chloride, keep warm at 30°C for 30min, and then enter the plate frame for filtration.

[0024] 3. The pressure difference between the inlet and outlet water of the control plate and frame filter is 0.04MPa. After the filter residue of the plate and frame filter is collected, it is treated as an organic fertilizer.

[0025] 4. The effluent from the plate frame enters the activated carbon filter for filtration. The amount of granular activated carbon added to the activated carbon filter is 2 / 3 of the column height, and the filtration rate is 15 column volumes / h. Then it enters the bag filter for fine filtration.

[0026] 5. The water pressure difference between the in...

Embodiment 2

[0031] The wastewater treatment and reuse process of isomaltooligosaccharide production is as follows:

[0032] 1. 200 tons of production wastewater, measured initial conductivity 2620μs / cm, pH6.55, COD4000mg / L.

[0033] 2. Add 30mg / L of polyaluminum chloride and 12mg / L of polyaluminum sulfate, keep warm at 35°C for 30min, and then enter the plate frame for filtration.

[0034] 3. The pressure difference between the inlet and outlet of the plate and frame filter is 0.04MPa. After the filter residue of the plate and frame filter is collected, it will be treated as an organic fertilizer.

[0035] 4. The effluent from the plate frame enters the activated carbon filter for filtration. The amount of granular activated carbon added to the activated carbon filter is 1 / 2 column height, and the filtration rate is 12 column volumes / h. Then it enters the bag filter for fine filtration.

[0036] 5. Multi-core bag filter (8 cores) has a pressure difference of 0.04MPa between the inlet and...

Embodiment 3

[0041] Dextrin production wastewater treatment and reuse process is as follows:

[0042] 1. 220 tons of production wastewater, measured initial conductivity 3350μs / cm, pH 5.49, COD 4500mg / L, added sodium hydroxide to adjust the pH to 6.6.

[0043] 2. Add 25mg / L of polyaluminum chloride, 10mg / L of polyaluminum sulfate, and 0.1mg / L of polyacrylamide, keep warm at 35°C for 30min, and then enter the plate frame for filtration

[0044] 3. The pressure difference between the inlet and outlet water of the control plate and frame filter is 0.04MPa. After the filter residue of the plate and frame filter is collected, it is treated as an organic fertilizer.

[0045] 4. The effluent from the plate frame enters the activated carbon filter for filtration. The amount of granular activated carbon added to the activated carbon filter is 3 / 4 of the column height, and the filtration rate is 13 column volumes / h. Then it enters the bag filter for fine filtration.

[0046] 5. The pressure differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com