Method for preparing degradable mulch by reusing organic waste residues of biomass

A technology for organic waste residue and plastic film degradation, applied in organic fertilizers, chemical instruments and methods, applications, etc., can solve problems such as imbalance of soil flora, difficulty in controlling fermentation conditions, pollution of harmful fungi, etc., to achieve the purpose of inhibiting the growth of weeds, The effect of solving bacterial pollution and moderate degradation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

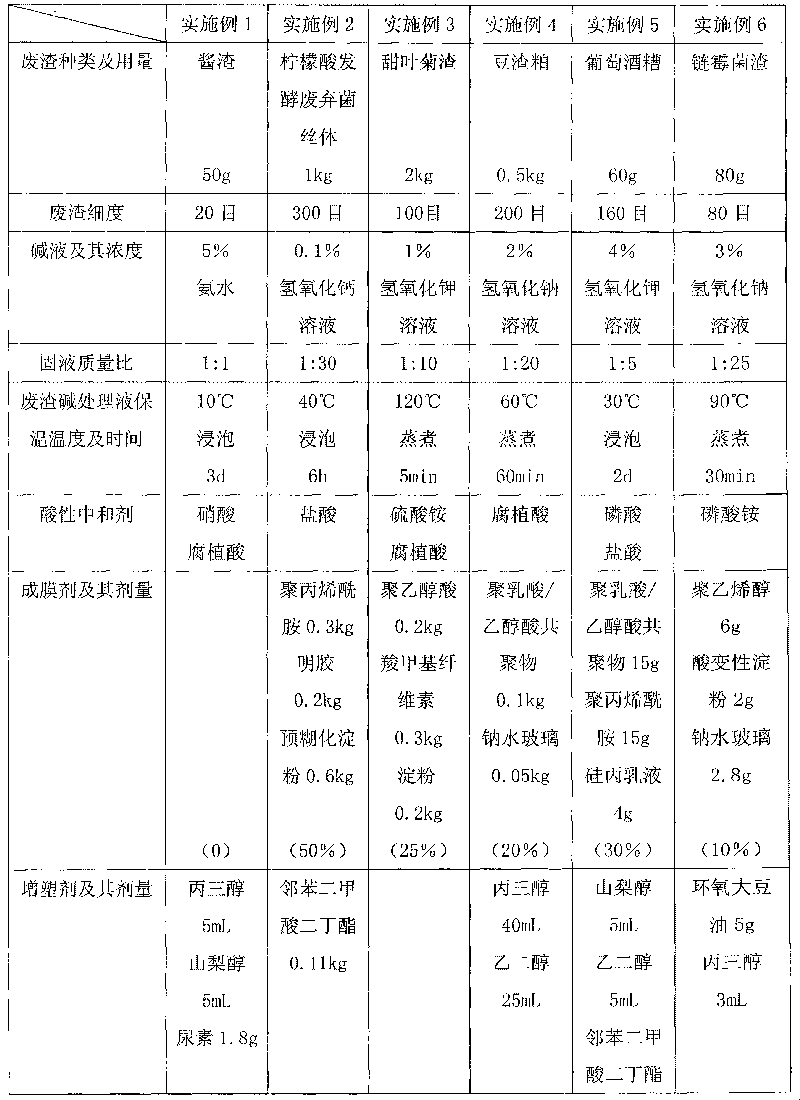

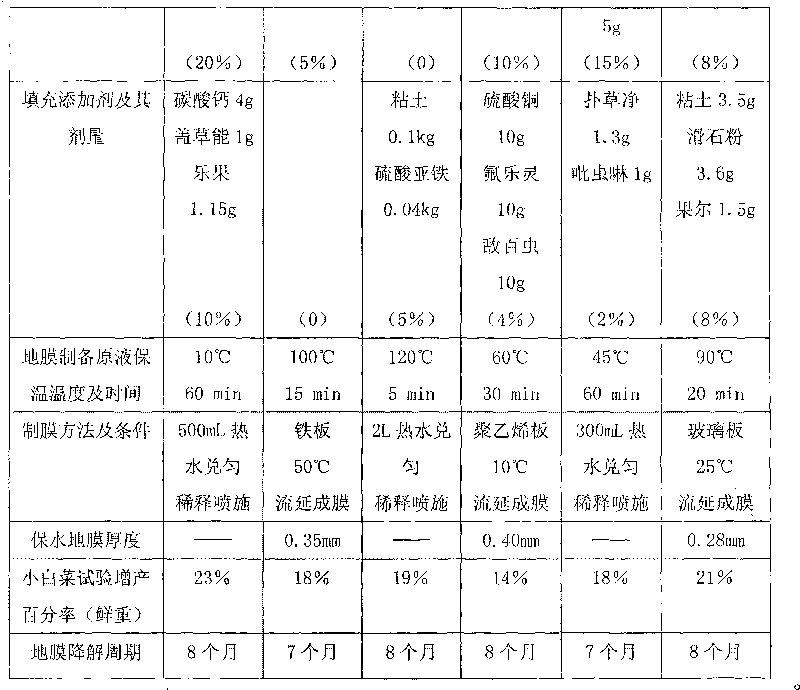

Embodiment 1

[0032] Take 50g of soy sauce crushed to 20 meshes, soak with 5% ammonia water at a mass concentration of 1:1, and soak at 10°C for 3 days, neutralize nitric acid and humic acid to neutrality, then add 5mL of glycerol, and 5mL alcohol, 1.8g urea, mixed with 4g calcium carbonate, 1g Gai Caoneng, 1.15g dimethoate, mix quickly, stir at 10°C and keep warm for 60 minutes, add 500mL hot water to mix evenly, dilute and spray on the soil surface . The yield increase rate of pakchoi planting test was 23%, and the degradation period was 8 months.

Embodiment 2

[0034] Take 1 kg of waste mycelia from citric acid fermentation that has been crushed to 300 mesh, use 0.1% calcium hydroxide solution with a mass concentration of 0.1%, solid-to-liquid mass ratio 1:30, keep warm at 40°C for 6 hours, neutralize hydrochloric acid to neutrality, and then add poly Acrylamide 0.3kg, gelatin 0.2kg, pregelatinized starch 0.6kg, supplemented with plasticizer dibutyl phthalate 0.11kg, stirred and kept at 100°C for 15 minutes, cast on iron plate, at 50°C Dry to form a degradable mulch film with an average film thickness of 0.35 mm. The yield increase rate of pakchoi planting test was 18%, and the degradation period was 7 months.

Embodiment 3

[0036] Take 2 kg of stevia rebaudiana slag crushed to 100 mesh, soak it with 1% potassium hydroxide solution with a mass concentration of 1:10, cook it at 120°C for 5 minutes, neutralize it with ammonium sulfate and humic acid, add 0.2kg of polyglycolic acid, 0.3kg of carboxymethyl cellulose, 0.2kg of starch, mixed with 0.1kg of clay, 0.04kg of ferrous sulfate fertilizer, mixed quickly and kept at 120°C for 5 minutes, added 2L of hot water and mixed evenly Then dilute and spray on the soil surface. The yield increase rate of pakchoi planting test was 19%, and the degradation period was 8 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com