Nitrogen-doped bagasse activated carbon and preparation method thereof

A sugarcane bagasse and activated carbon technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of complex preparation process, and achieve the effects of simple preparation method, prevention of mass loss, and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

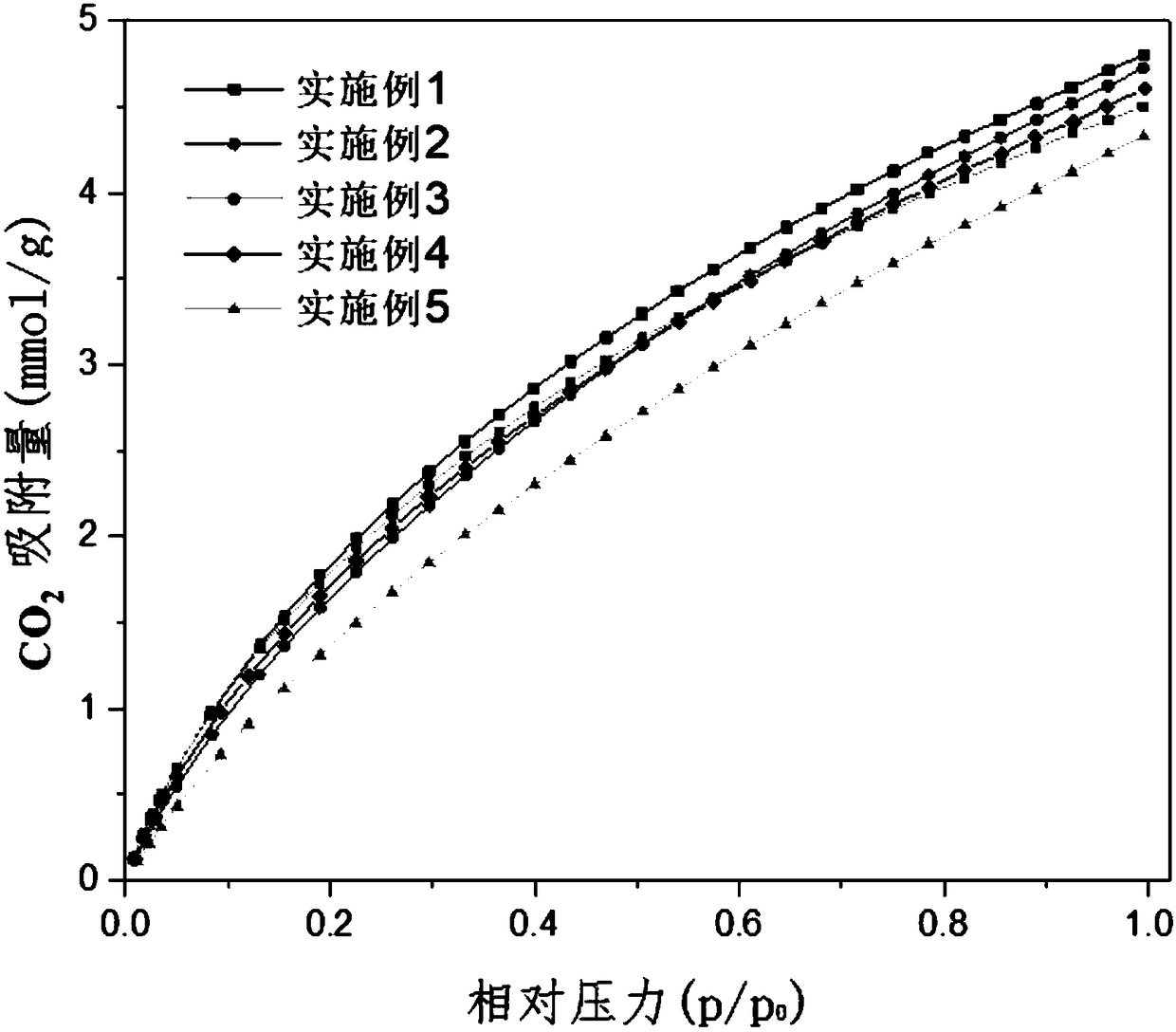

Embodiment 1

[0023] The bagasse is fully pulverized, sieved to 2-6mm, washed with deionized water for 3-5 times, and dried in a blast drying oven at 80-105°C to obtain the bagasse, which is set aside. The dried bagasse is mixed with urea accounting for 15% by weight of the bagasse, and an appropriate amount of deionized water is added, soaked for 12 hours, and dried. The above mixture was carbonized in a tube furnace at 600°C under a nitrogen atmosphere for 0.5h, taken out after cooling, rinsed repeatedly with deionized water for 6-10 times, and dried at 105°C to obtain a carbonized precursor.

[0024] The carbonization precursor and KOH were sampled at a mass ratio of 1:2. Dissolve KOH in an appropriate amount of deionized water, stir well and add the carbonized sample. After soaking for 12 hours, dry it in an oven at 95-110°C and transfer it to a tube Activate in a furnace at 600°C for 1 hour under a nitrogen atmosphere. After the sample is cooled to room temperature, it is washed with 1...

Embodiment 2

[0027] The bagasse is fully pulverized, sieved to 2-6mm, washed with deionized water for 3-5 times, and dried in a blast drying oven at 80-105°C to obtain the bagasse, which is set aside. The dried bagasse is mixed with urea accounting for 20 wt% of the bagasse, and an appropriate amount of deionized water is added, soaked for 8 hours, and dried. The above mixture was carbonized in a tube furnace at 600 °C under a nitrogen atmosphere for 1 h, taken out after cooling, rinsed repeatedly with deionized water for 6 to 10 times, and dried at 105 °C to obtain a carbonized precursor.

[0028]The carbonization precursor and KOH were sampled according to the mass ratio of 1:2, KOH was dissolved in an appropriate amount of deionized water, and the carbonized sample was added after fully stirring. Activate in a nitrogen atmosphere at 600°C for 1 hour in a nitrogen atmosphere. After the sample is cooled to room temperature, wash it with 1mol / L HCl for 2 to 3 times, then wash it repeatedly...

Embodiment 3

[0031] The bagasse is fully pulverized, sieved to 2-6mm, washed with deionized water for 3-5 times, and dried in a blast drying oven at 80-105°C to obtain the bagasse, which is set aside. The dried bagasse is mixed with urea accounting for 15% by weight of the bagasse, and an appropriate amount of deionized water is added, soaked for 10 hours, and dried. The above mixture was carbonized in a tube furnace at 500°C under a nitrogen atmosphere for 0.5h, taken out after cooling, rinsed repeatedly with deionized water for 6-10 times, and dried at 105°C to obtain a carbonized precursor.

[0032] The carbonization precursor and KOH were sampled according to the mass ratio of 1:3, KOH was dissolved in an appropriate amount of deionized water, and the carbonized sample was added after fully stirring. Activate in a furnace at 600°C for 1 hour under a nitrogen atmosphere. After the sample is cooled to room temperature, it is washed with 1mol / L HCl for 2 to 3 times, then repeatedly washed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com