Sucrose waste molasses aquiculture feed and preparation method thereof

A technology of aquatic feed and waste molasses, which is applied in animal feed, animal feed, applications, etc., can solve the problems of increasing production costs, and there is no official report on the application of sucrose waste molasses, so as to reduce recycling costs and alleviate low economic benefits , The effect of reducing production cost and breeding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

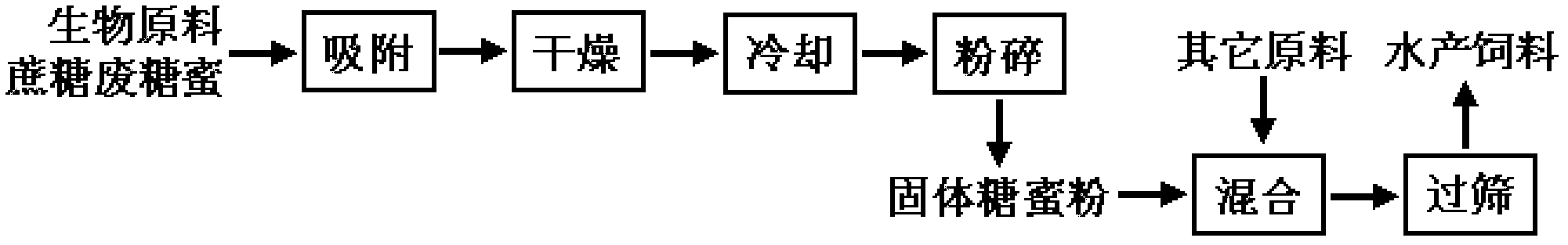

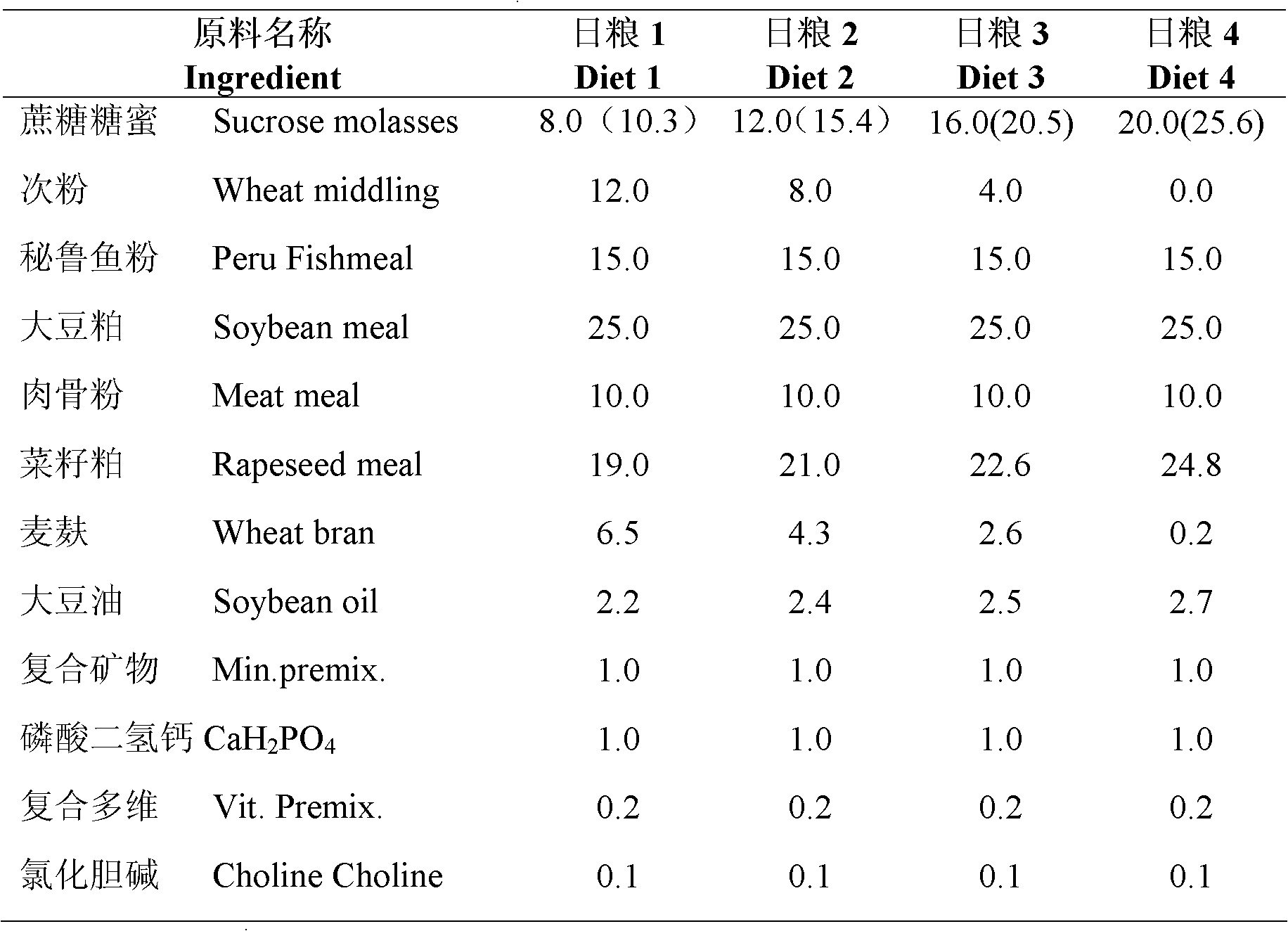

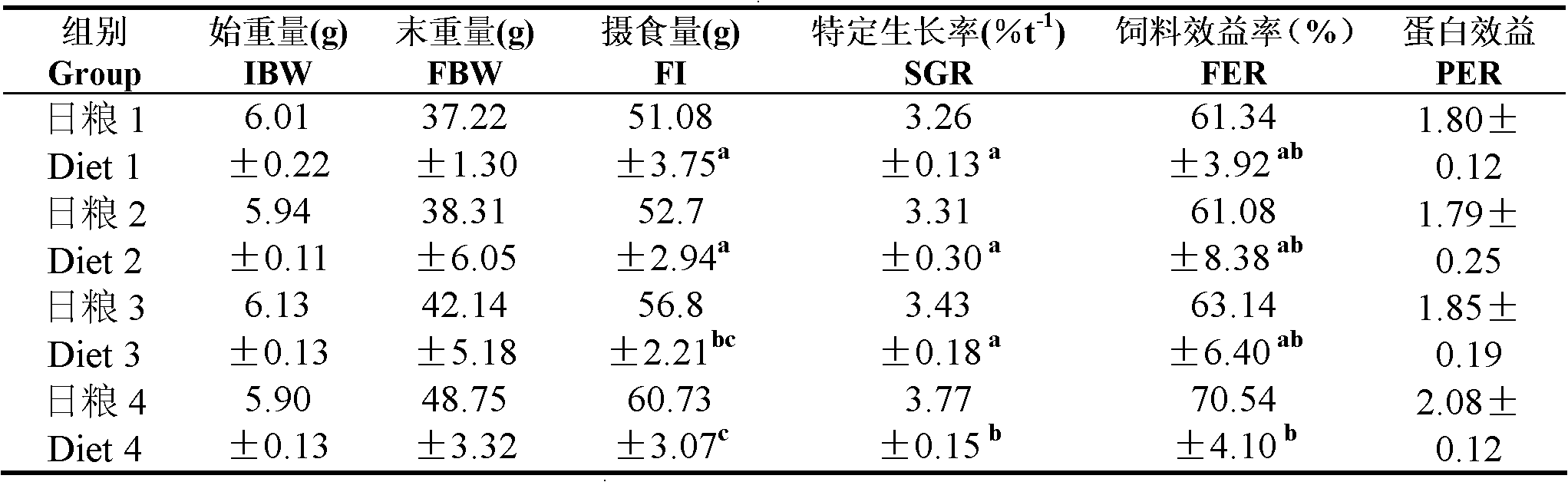

[0032] According to the feed formulation requirements of juvenile tilapia juveniles (see Table 1 for the specific formula), 4 kinds of aquatic feeds containing 8 parts, 12 parts, 16 parts and 20 parts of sucrose waste molasses are set to be converted into sucrose waste molasses respectively Parts by weight: 40 parts, 60 parts, 80 parts, 100 parts gradually replace secondary powder. Wheat bran, rapeseed meal, soybean meal and sucrose molasses are uniformly mixed in proportion to form a mixture containing sucrose molasses in different proportions; the above mixture is fully dried at a hot air temperature of 75-95°C until the water content is less than 12%; Place the dried mixture under airtight conditions to allow it to cool naturally; put the dried mixture into a pulverizer, stir evenly and pulverize, pass through a 40-mesh sieve to form solid molasses powder with high content of sucrose waste molasses; according to the table Add other raw materials to the production feed formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com