Gypsum retarder capable of improving strength and binding strength of gypsum base material

A gypsum retarder and bond strength technology, applied in the field of gypsum retarder, can solve the problems of gypsum product strength and bond strength loss, increase in strength and bond strength loss rate, gypsum strength and bond strength influence and other issues , to achieve the effect of strong adaptability of gypsum, improved strength and bond strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Formula

[0022] Polyvinyl alcohol 35%

[0023] Bone glue with a fineness of 250 mesh 10%

[0025] Instant Methyl Hydroxypropyl Cellulose Ether 1%

[0026] Fineness of 300 mesh heavy calcium powder 39%

[0027] 2. Preparation

[0028] Weigh raw materials according to the above ratio, stir in a dry powder mixer for 15 minutes, and pack.

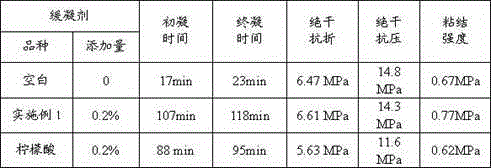

[0029] 3. Performance test

[0030] Get three parts of Sichuan Longyuan brand building gypsum with the same specifications, one part does not add retarder, one part adds the retarder prepared in Example 1 of 0.2% of building gypsum weight, one part adds 0.2% of building gypsum weight Citric acid, according to GB / T 17669.4-1999 "Determination of Physical Properties of Building Gypsum Plaster" and GB / T 17669.3-1999 "Determination of Mechanical Properties of Building Gypsum" standards, the various properties of building gypsum are tested, and the results are as follows:

[0031]

Embodiment 2

[0033] 1. Formula

[0034] Polyvinyl alcohol 25%

[0035] 300 mesh blood protein glue 20%

[0037] Instant Methyl Hydroxypropyl Cellulose Ether 0.5%

[0038] Dolomite powder with a fineness of 350 mesh 44.5%

[0039] 2. Preparation

[0040] Weigh the raw materials according to the ratio in the above table, stir in a dry powder mixer for 15 minutes, and pack.

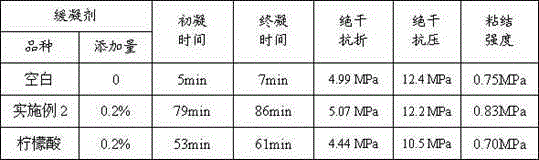

[0041] 3. Performance test

[0042] Take three parts of Sichuan Hongda Group industrial by-product gypsum-phosphogypsum with the same specifications, one part does not add retarder, one part adds the retarder prepared in Example 2 with 0.2% by weight of phosphogypsum, and one part adds 0.2% citric acid by weight of phosphogypsum, according to GB / T 17669.4-1999 "Determination of physical properties of building gypsum paste" and GB / T 17669.3-1999 "Determination of mechanical properties of building gypsum" to test the various properties of phosphogypsum , the result is as follows:

[0043]...

Embodiment 3

[0045] 1. Formula

[0046] Polyvinyl alcohol 35%

[0047] 300 mesh blood protein glue 25%

[0049] Instant Methyl Hydroxypropyl Cellulose Ether 0.7%

[0050] Fineness of 300 mesh heavy calcium powder 24.3%

[0051] 2. Preparation

[0052] Weigh the raw materials according to the ratio in the above table, stir in a dry powder mixer for 15 minutes, and pack.

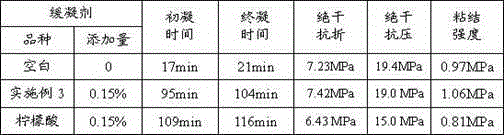

[0053] 3. Performance test

[0054] Take three parts of Chongqing Luohuang Power Plant's by-product gypsum with the same specifications - desulfurization gypsum, one part does not add retarder, one part adds the retarder prepared in Example 3 with 0.2% by weight of desulfurization gypsum, and one part adds phosphorus Gypsum weight 0.2% citric acid, in accordance with GB / T 17669.4-1999 "Determination of Physical Properties of Building Gypsum Plaster" and GB / T 17669.3-1999 "Determination of Mechanical Properties of Building Gypsum" to test the various properties of desulfurized gypsum, The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com