Method for improving sulfurous method production process in cane sugar factory

A sulfite method and production process technology, applied in the direction of using physical methods to purify, using adsorbents to purify, etc., can solve the problems of low sugar yield, easy formation of flocculent precipitation, and reduced recovery rate, and achieve a simple and easy production process. Achieve the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] 1. Clarify the material with activated carbon

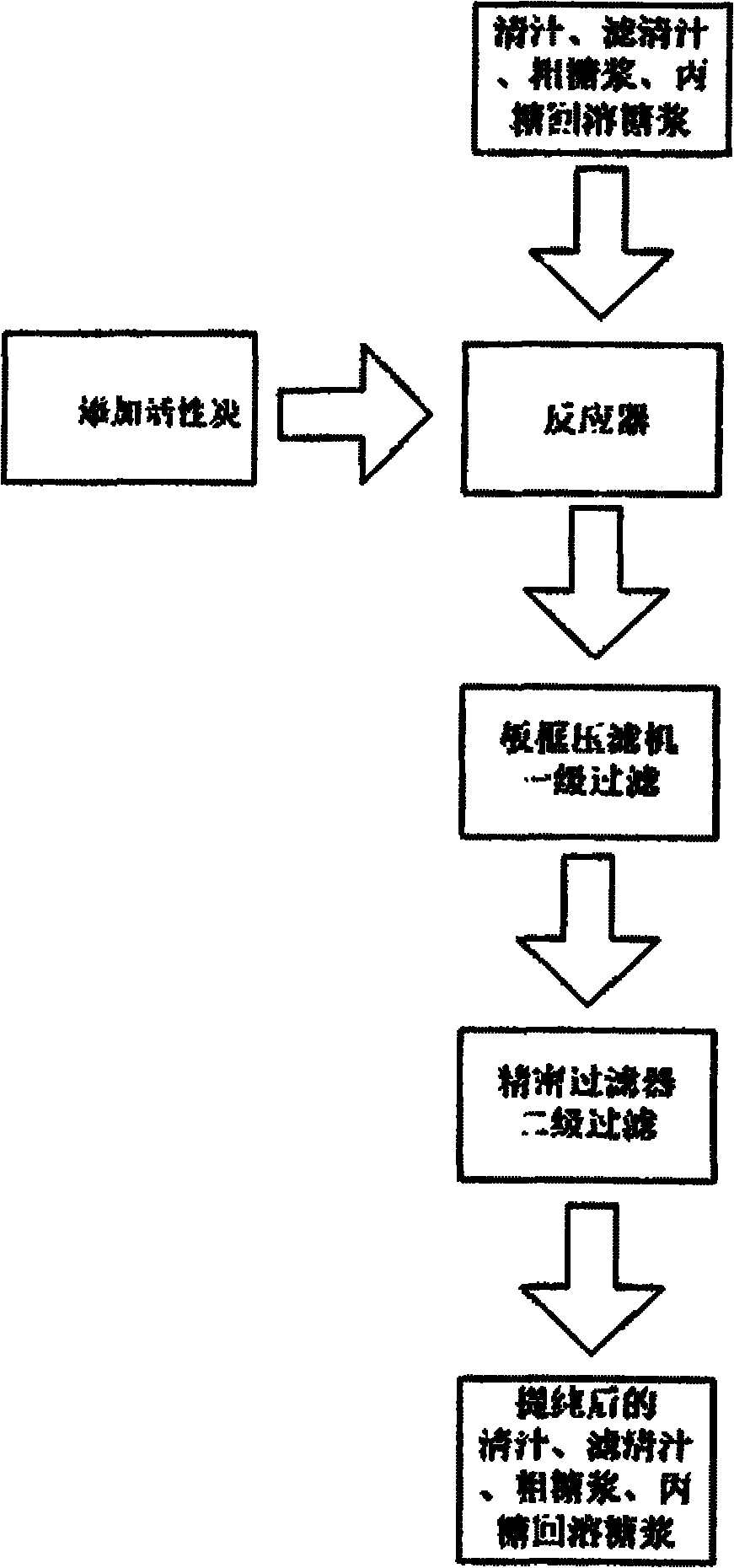

[0016] Extract the clear juice, filtered juice, rough syrup or triose redissolved syrup from the original production process, and add activated carbon to the clear juice, filtered juice, coarse syrup or triose redissolved syrup in the reactor according to 0.5-3.0% of the syrup mass , React at 60-90°C for 15-30 minutes to perform physical adsorption, impurity removal, and decolorization.

[0017] 2. Solid-liquid separation of activated carbon and materials

[0018] After the adsorption, clear juice, filtered juice, coarse syrup or triose redissolved syrup are discharged from the reactor, and are subjected to secondary filtration and solid-liquid separation through plate and frame filter press and precision filter, and high-purity clear juice is obtained after filtration , filtered juice, coarse syrup or triose redissolved syrup re-enter the original production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com