Total recycling method of PCB (printed circuit board) nitric acid type tin-lead stripping waste liquid

An all-resource, tin stripping technology, applied in chemical instruments and methods, ferric sulfate, process efficiency improvement, etc., can solve the problems of high energy consumption, high cost, low recovery rate, etc., achieve good sedimentation effect, low cost, The effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

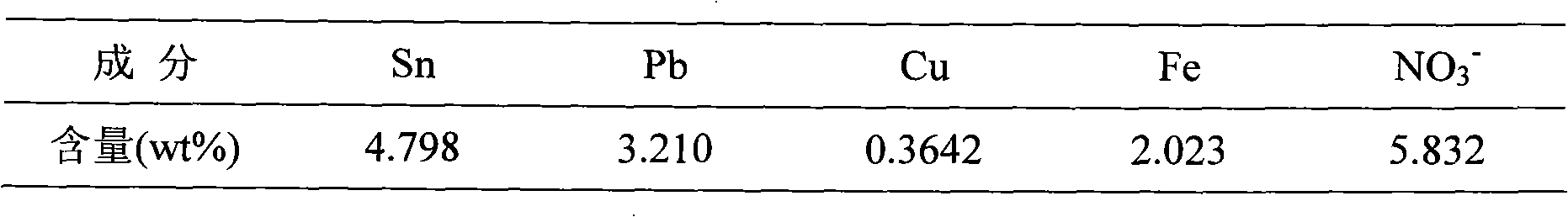

[0037] The composition analysis of WSP is shown in Table 1:

[0038] Table 1

[0039]

[0040] Introduce 25368kg of the above WSP into the 30m with stirring (7.5kW, 16rpm) 3 Buried type reaction tank, add 2400kg concentration under agitation condition and be the ferrous sulfate heptahydrate solution of 50wt%, finish adding in 1 hour, continue to stir, react 0.5 hour to obtain reaction solution, reaction solution is filtered and separated solid by plate-and-frame filter Liquid phase, the obtained filter cake is washed with 1000kg of clear water, and the filtrate and cleaning solution are combined into mother liquor, and the filter cake is tin-lead mud. The total amount of tin-lead mud is 12294kg, containing 9.839wt% of tin and 6.619wt% of lead (the extraction rates of corresponding tin and lead are respectively 99.38% and 99.93%); The mother liquor of wt%) is moved into the buffer tank, fills up the contact reactor with 1000kg iron shavings, then starts the acid-resistant ...

Embodiment 2

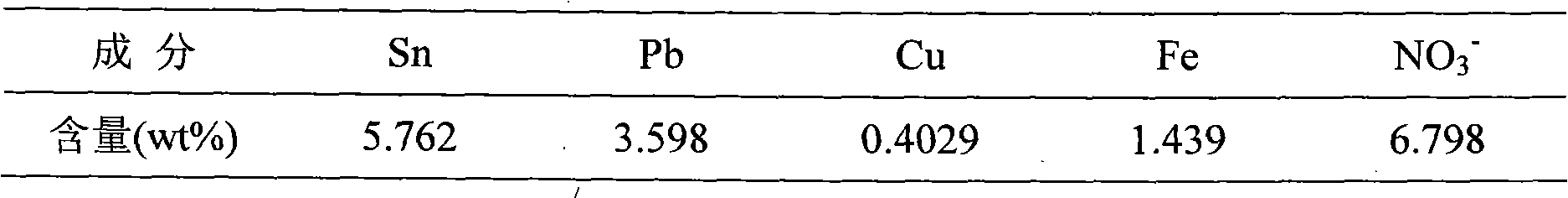

[0043] Implementation method and step are with embodiment 1, wherein in WSP, continue to stir after adding ferrous sulfate heptahydrate solution for 1 hour, the component analysis of WSP is as shown in table 2:

[0044] Table 2

[0045]

[0046] Wherein WSP is 24983kg, 50wt% ferrous sulfate heptahydrate solution 3600kg, tin-lead mud total amount 14408kg, wherein contains tin 9.958wt%, contains lead 6.237wt% (the extraction rate of tin, lead is respectively 99.67% and 99.97%); The total amount of mother liquor is 15672kg, which contains 0.6423wt% copper and 4.591wt% iron. The total iron consumption in the copper extraction process is 1135kg, the sponge copper is 113.8kg, and contains 88.01wt% copper (copper extraction rate is 99.50%); the total amount of raffinate is 15540kg, which contains 11.93wt% iron. Adding 11,550kg of ferrous sulfate heptahydrate and 2,000kg of concentrated sulfuric acid to the system can produce about 29,000kg of modified polyiron, with an iron conte...

Embodiment 3

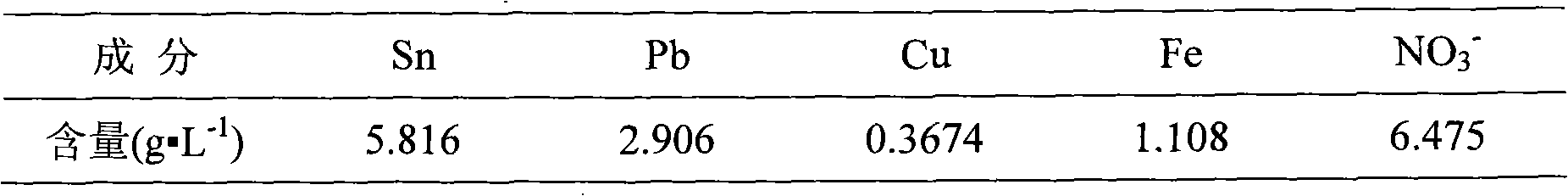

[0048] Implementation method and step are with embodiment 1, wherein continue to stir 2 hours after adding ferrous sulfate heptahydrate solution in WSP, the component analysis of WSP is as shown in table 3:

[0049] table 3

[0050]

[0051] WSP is 25143kg, 50wt% ferrous sulfate heptahydrate solution 5300kg, extracts tin-lead mud total amount 13542kg, wherein contains tin 10.79wt%, contains lead 5.395wt% (the extraction rate of tin is 99.92%, the extraction rate of lead is 99.99%); The total amount of mother liquor after extracting the tin-lead mud is 18506kg, which contains 0.4992wt% copper and 4.369wt% iron. The total iron consumption in the copper extraction process is 1048kg, the sponge copper is 122.2kg, and the copper content is 75.10wt% (copper extraction rate is 99.35%); the total amount of residual liquid after copper extraction is 19387kg, and the iron content is 9.575wt%. Add 5,000kg of ferrous sulfate heptahydrate and 1,500kg of concentrated sulfuric acid to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com