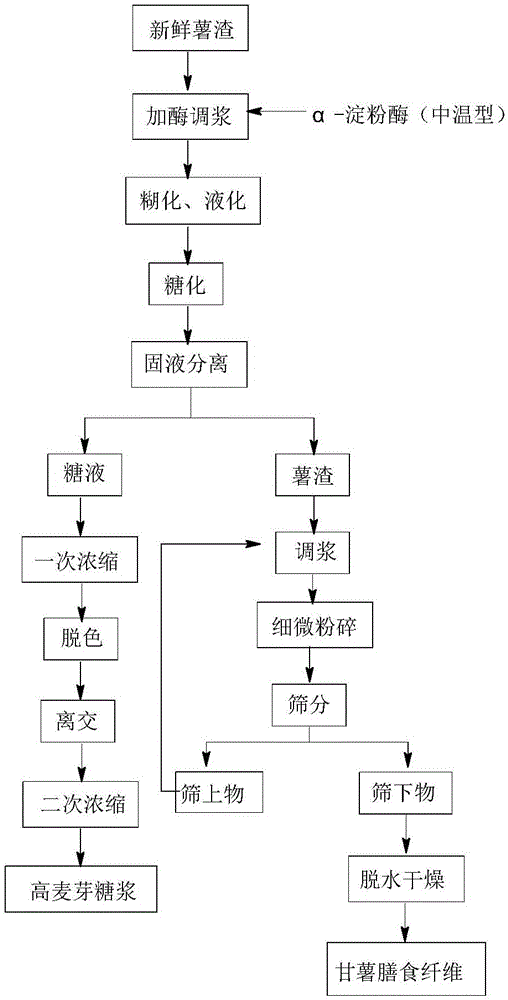

Production method for preparing high maltose syrup and dietary fibers by processing waste residues by means of sweet potato starch

A technology of high maltose syrup and sweet potato starch, which is applied in sugar production, maltose production, sugar production, etc., can solve the problems of insufficient utilization of sweet potato dregs, etc., and achieve the advantages of reuse, low glucose content and high maltose content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

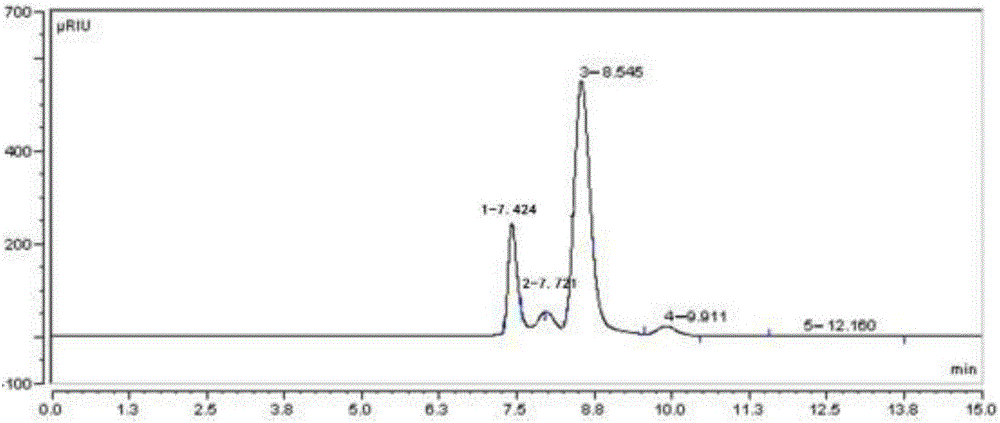

[0057] Take 10kg of fresh potato residue (produced by sweet potato starch processing, water content 88%, starch content 52.5% (dry basis), β-amylase activity 156U / g fresh potato residue), add α-amylase (Novozymes BAN480L) 0.3g / kg starch, after stirring evenly, heat to 80-85°C, keep warm for 5min, measure DE value to 15.8%, cool down to 63±2°C, measure DE value to 49.6% after keep warm and saccharify for 5 hours, filter, filter residue with a small amount of water Wash and combine the filtrates, a total of 13.2L, with a solid content of 4.4%, and concentrate the sugar solution under reduced pressure to a solid content of 20%. Add 6g of activated carbon to the concentrated sugar solution, raise the temperature to 80°C, and keep it warm for 30 minutes for decolorization. The decolorized sugar solution is ion-exchanged, and the impurities are removed in the order of cation-yin-yang. The cation resin is 732 type cation exchange resin, and the anion resin is D315 type anion exchang...

Embodiment 2

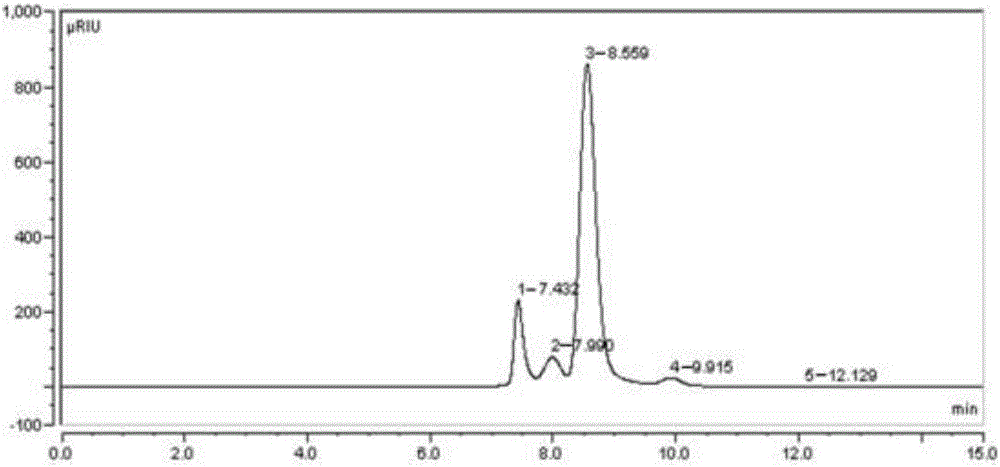

[0059] Take 15kg of fresh potato dregs (produced by sweet potato starch processing, water content 89%, starch content 48.5%, β-amylase activity 138U / g), add α-amylase (Novozymes BAN480L) 0.4g / kg starch, stir well , heated to 80-85°C, kept warm for 8 minutes, measured DE value was 21.4%, cooled to 60°C, and measured DE value reached 51.6% after 8 hours of heat preservation and saccharification, filtered, and the filter residue was washed with water to obtain a total of 18L filtrate with a solid content of 4.2 %, the sugar solution is concentrated under reduced pressure to a solid content of 20%. Add activated carbon to the concentrated sugar solution, keep warm and decolorize. The decolorized sugar solution is ion-exchanged, and the conductance of the outflowing sugar solution is controlled below 150 μs / cm. The sugar solution after ion exchange was concentrated under reduced pressure to a solid content of 78%, and a total of 0.93 L of maltose syrup was obtained. Detected by H...

Embodiment 3

[0061] Take 15kg of fresh potato dregs (water content 89%, starch content 49.8%, β-amylase activity 191U / g), add α-amylase (Novozymes BAN480L) 0.5g / kg starch, stir well, heat to 80- 85°C, heat preservation and liquefaction for 4 minutes, the measured DE value is 28.5%, lower the temperature to 60°C, and measure the DE value to 50.2% after heat preservation and saccharification for 2 hours, filter to obtain the saccharification liquid, concentrate the sugar liquid to a solid content of 20%, and then add activated carbon for heat preservation discoloration. The decolorized sugar solution is ion-exchanged, and the conductance of the outflowing sugar solution is controlled below 150 μs / cm. The sugar solution after ion exchange is concentrated to a solid content of 80%. The maltose content reaches 83.1% and the glucose content is 0.6% as detected by HPLC. The saccharified sweet potato dregs were mixed with water, finely pulverized, passed through a 120-mesh sieve, and dried to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com