Full resource utilization process of titanium white waste acid

A technology of titanium dioxide waste acid and all resources, which is applied to the improvement of process efficiency, the preparation/treatment of rare earth metal compounds, manganese sulfate, etc., can solve the problems of high recycling cost, occupying land resources, complicated process, etc., and achieve good promotion foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

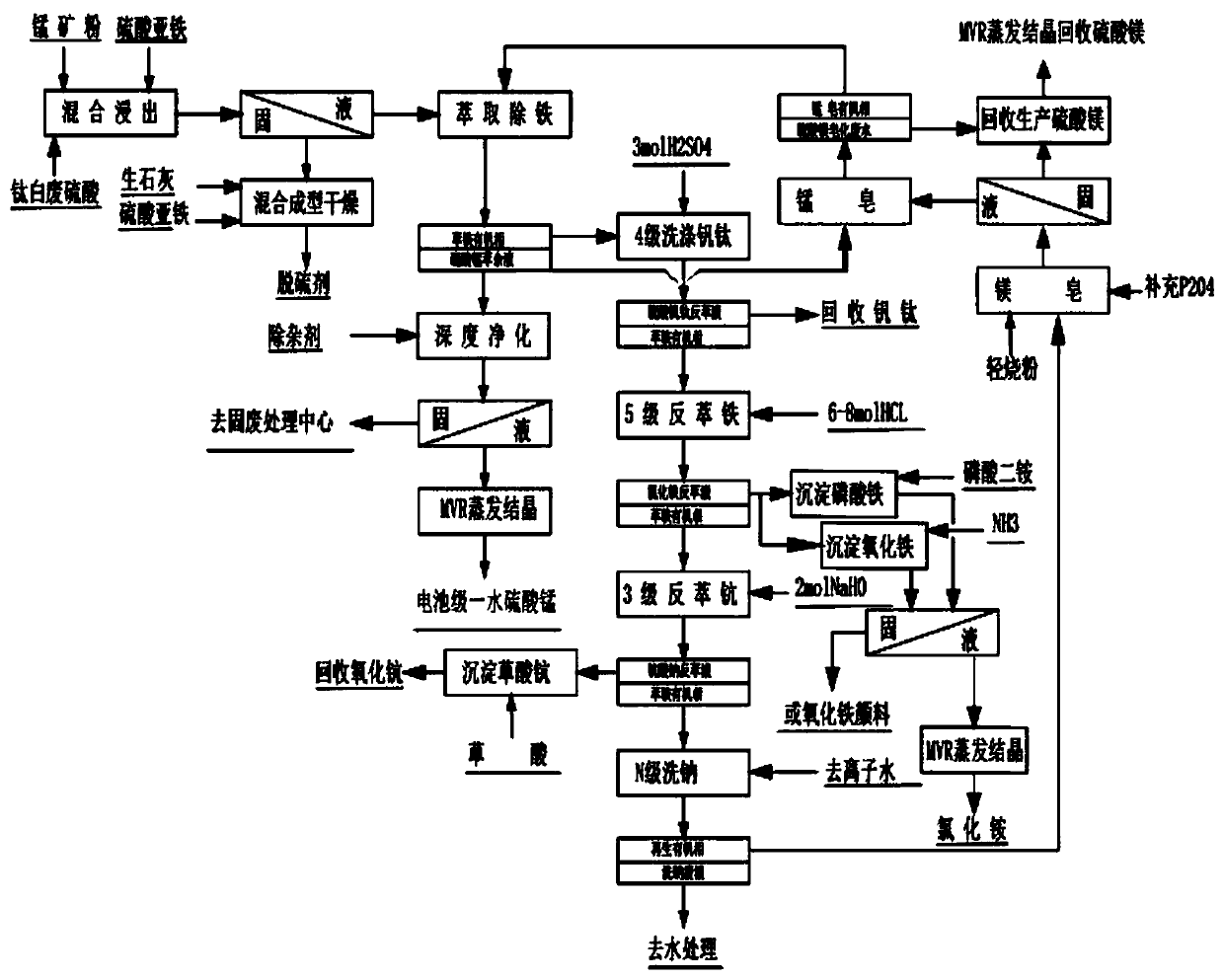

[0016] A process for fully resource utilization of titanium dioxide waste acid, specifically comprising the following steps:

[0017] 1) Use titanium dioxide waste acid and ferrous sulfate to reduce leaching manganese oxide ore to make iron oxide normal temperature desulfurizer: use manganese oxide ore to oxidize iron ions in titanium dioxide waste acid, and use titanium dioxide waste acid and ferrous sulfate to reduce leaching and oxidation The manganese ions in the manganese ore are subjected to solid-liquid separation after leaching to obtain solid leaching slag and leaching iron and manganese sulfate solution, adding ferrous sulfate lime to the solid leaching slag, mixing, extruding and forming, and drying to obtain iron oxide desulfurizer at room temperature;

[0018] 2) magnesium soap extraction is carried out to leaching iron and manganese sulfate solution to separate iron and manganese: magnesium oxide saponification P204 technology is adopted for leaching iron and mang...

Embodiment 2

[0021] A process for fully resource utilization of titanium dioxide waste acid, specifically comprising the following steps:

[0022] 1) Use titanium dioxide waste acid and ferrous sulfate to reduce leaching manganese oxide ore to make iron oxide normal temperature desulfurizer: use manganese oxide ore to oxidize iron ions in titanium dioxide waste acid, and use titanium dioxide waste acid and ferrous sulfate to reduce leaching and oxidation The manganese ions in the manganese ore are subjected to solid-liquid separation after leaching to obtain solid leaching slag and leaching iron and manganese sulfate solution, adding ferrous sulfate lime to the solid leaching slag, mixing, extruding and forming, and drying to obtain iron oxide desulfurizer at room temperature;

[0023] 2) magnesium soap extraction is carried out to leaching iron and manganese sulfate solution to separate iron and manganese: magnesium oxide saponification P507 technology is adopted to leaching iron and manga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com