Full-resource iron tailing utilization method

A technology of iron tailings and all resources, applied in the field of recycling of solid waste resources, can solve the problems of low mechanical properties and narrow application range, and achieve the effects of promoting plant growth, reducing production costs, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

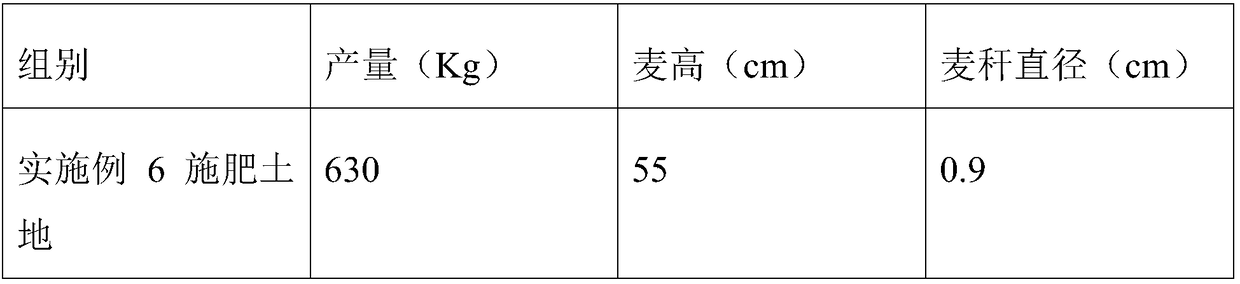

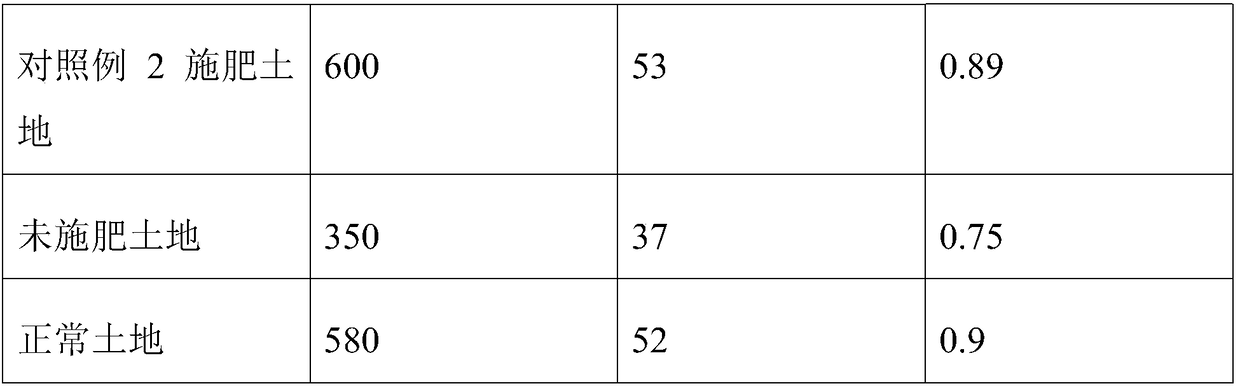

Examples

Embodiment 1

[0081] This embodiment is a method for fully utilizing iron tailings resources, including the following steps:

[0082] Step 1: Send the iron tailings to a 30mm-class screening machine through a feeder for pre-screening, and obtain materials with a particle size greater than 30mm and materials with a particle size less than 30mm respectively;

[0083] Step 2: Put the material with a particle size greater than 30mm into a crusher to be crushed to a particle size less than 30mm, and mix with the material with a particle size less than 30mm obtained in step 1, to obtain a mixed material;

[0084] Step 3: Pass the mixture through a 10mm-class sieving machine, and sieving to obtain coarse aggregates with a particle size of 10-30mm and materials with a particle size of less than 10mm;

[0085] Step 4. Put the material with a particle size of less than 10mm into the crusher for crushing, and then pass the crushed material through a 5mm-class sieving machine to obtain medium aggregates with a ...

Embodiment 2

[0092] This embodiment is the preparation method of iron tailing-based mineral compound fertilizer in embodiment 1, including the following steps:

[0093] Step 1: Mix 50 parts of iron tailings powder, 10 parts of saw mud, 10 parts of sedimentation mud, and 30 parts of potassium hydroxide to obtain a mixture material;

[0094] Step two, calcining the mixture, calcining at 1050°C for 3 hours, and then cooling to room temperature;

[0095] Step 3. Crush the cooled mixture to 300 meshes to obtain iron tailing-based mineral compound fertilizer;

[0096] The iron tailing-based mineral compound fertilizer prepared above was tested according to the corresponding test method of the chemical industry standard HG 2557-94 calcium-magnesium phosphate fertilizer standard of the People’s Republic of China. The active ingredient content is K 2 O is 22.10%, SiO 2 It is 26.50%, MgO is 2.86%, and CaO is 5.17%.

Embodiment 3

[0098] This embodiment is the preparation method of iron tailing-based mineral compound fertilizer in embodiment 1, including the following steps:

[0099] Step 1: Mix 50 parts of iron tailings powder, 15 parts of saw mud, 10 parts of sedimentation mud, and 30 parts of potassium hydroxide to obtain a mixture material;

[0100] Step two: calcining the mixed material, calcining at 1100°C for 2h, and then cooling to room temperature;

[0101] Step 3: Crush the cooled mixture to 120 meshes to obtain iron tailing-based mineral compound fertilizer.

[0102] The detection method of Example 2 was used to detect the iron tailing-based mineral compound fertilizer prepared above, and its effective ingredient content was: K 2 O is 23.10%, SiO 2 29.00%, MgO 2.96%, CaO 6.17%

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com