A complex energy-saving and high-efficiency desulfurization, denitrification and dust removal integrated purification tower

A desulfurization, denitrification and desulfurization tower technology, applied in the field of environmental protection equipment, can solve the problems of consumption of limestone resources, heavy burden on enterprises, and easy damage of equipment, etc., and achieve the effect of good dust removal effect, small initial investment and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

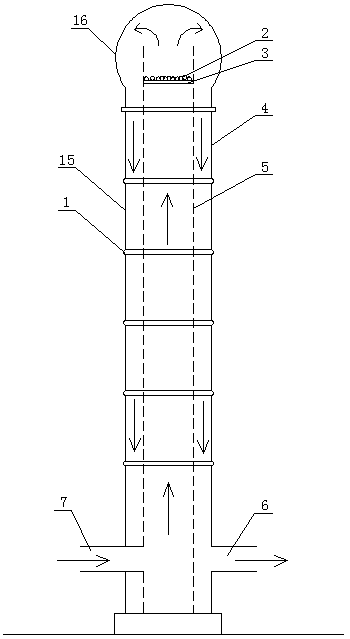

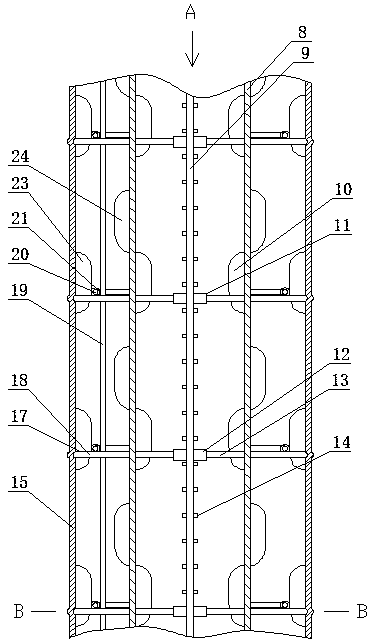

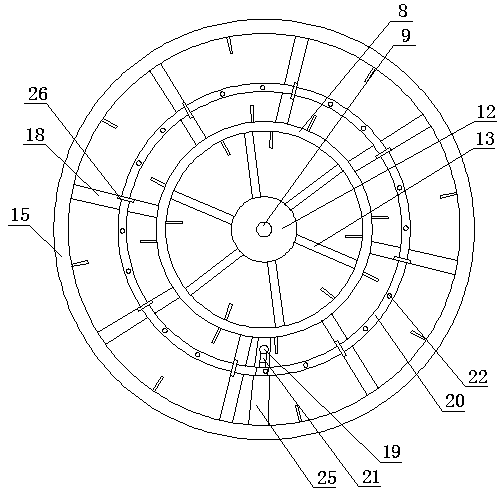

[0025] Such as figure 1 As shown in -4, the complex energy-saving and high-efficiency desulfurization, denitrification and dust removal integrated purification tower includes a desulfurization device 5 and a denitration device 4 made of polymer materials, and the desulfurization device 5 is arranged in the inner cavity of the denitrification device 4 .

[0026] The desulfurization device 5 includes a desulfurization tower 8 and a desulfurizer main pipe 9. The desulfurization tower 8 is arranged vertically and has an upper end opening. The third waveguide blade 10 is connected in the desulfurization tower 8. The grid filter layer 3 is connected to the upper end of the desulfurization tower 8. A purifying filler 2 is arranged on the mesh filter layer 3 . The desulfurizer main pipe 9 is vertically fixed in the desulfurization tower 8 through multiple sets of support assemblies 11, each set of support assemblies 11 includes a support base 12 and six support shafts 13, each support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com