Method for preparing semi-solid alloy rheological slurry or billet through annular-gap type electromagnetic stirring

A semi-solid slurry and electromagnetic stirring technology is applied in the field of preparation of semi-solid metal or alloy slurry or billet, which can solve the problem of inability to produce semi-solid alloy slurry or billet, slurry temperature field, slurry structure inhomogeneity, It is not easy to produce semi-solid slurries or billets, etc., to avoid adverse effects, ideal structure distribution, and good shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The main embodiment of the preparation of semi-solid metal rheological slurry or blank of the present invention is:

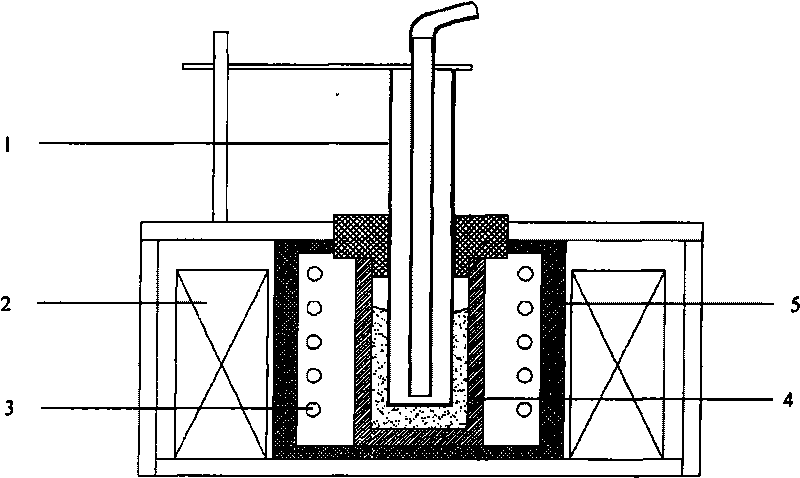

[0036] Such as figure 1 As shown, the internal cooling controller 1 is a cooling passage with a cooling medium in it. The cooling passage is composed of a central tube and its outer casing. In the same way, the central tube constitutes the cooling medium input channel; the upper opening of the outer sleeve is the cooling medium output port, and the internal cooling controller 1 can pass into the cooling medium. The external cooling controller 3 is a spiral tube with a plurality of evenly distributed small holes, which are placed inside the external thermal insulation material 5 of the pulping chamber 4 and at a certain distance from the wall of the pulping chamber. The external cooling controller 3 The cooling medium can also be passed inside. The pulping chamber is a cylindrical container, which is placed inside the insulation material to form a close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com